Metal substrate with thermally-sprayed anti-sticking wear-resistant coating and preparation method as well as application thereof

A metal substrate, wear-resistant coating technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of non-stick performance failure, large peeling force, insufficient wear resistance, etc. The effect of light adhesive peel force, improved surface strength, excellent abrasion resistance and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

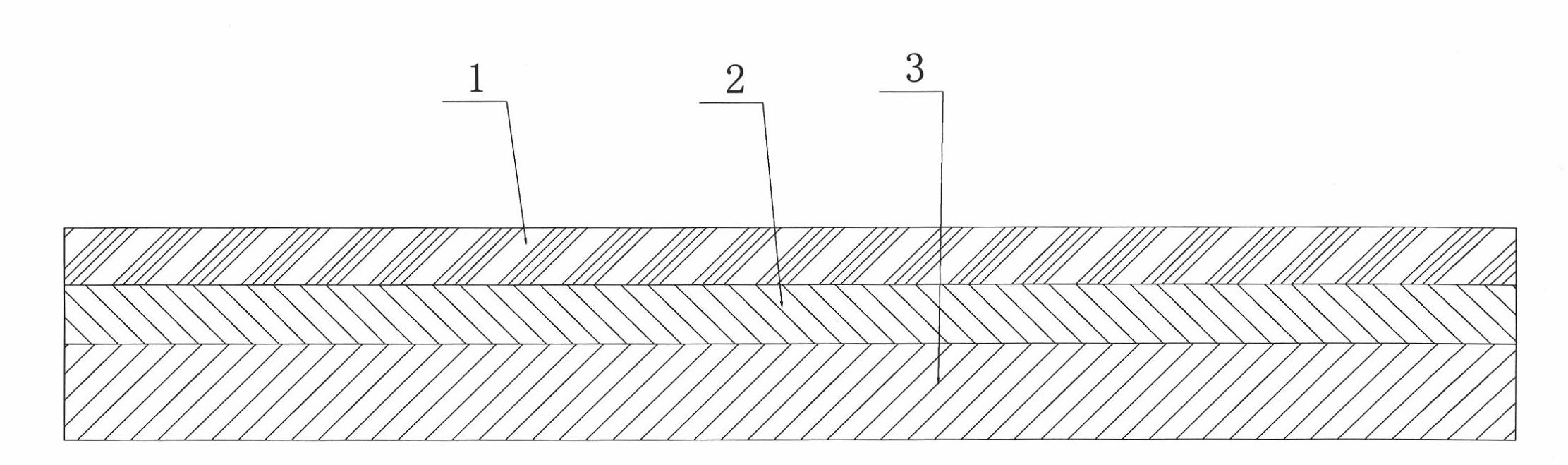

[0028] Such as figure 1 Shown is a metal substrate 3 with thermal spraying anti-sticking and wear-resistant coating, the surface of the metal substrate 3 is provided with a nickel-based alloy coating 2, and the surface of the nickel-based alloy coating 2 is dispersed and bonded with silicon polymerization The material resin layer 1, the silicon polymer resin layer 1 is cured and cross-linked by addition type siloxane resin. The layer thickness of the nickel-based alloy coating 2 is 120 μm, and the surface hardness is HRC50˜HRC60.

[0029] The formulation of the nickel-based alloy coating 2 in this embodiment is as follows: C 0.5-1.1%, Si 3.0-5.5%, B 3.0-4.5%, Cr 15-30%, Fe=5.0%, and the balance is Ni.

[0030] The silicone polymer resin is commercially available from Ningbo Chemical Industry Co., Ltd.: A component: addition type siloxane; B component: composite platinum catalyst.

[0031] The above-mentioned method for the metal substrate with thermal spraying anti-sticking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com