Pressure-sensitive optical cable and manufacture method thereof

A pressure-sensitive, optical cable technology, applied in the direction of force measurement, fiber mechanical structure, etc. by measuring the change of optical properties of materials when they are stressed, which can solve unfavorable costs and mass production, limit the use of optical fiber sensors, production, packaging, etc. , transportation, difficulty in use and other problems, to achieve the effect of convenient processing, flexible use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

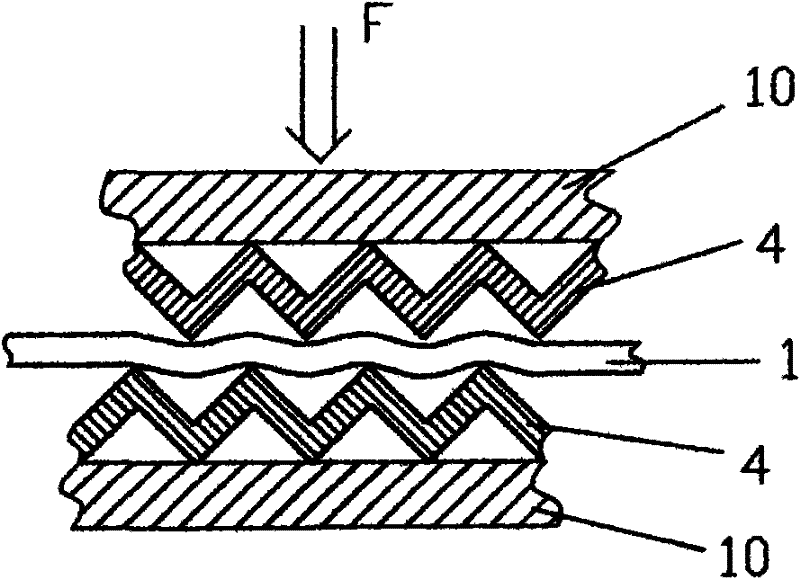

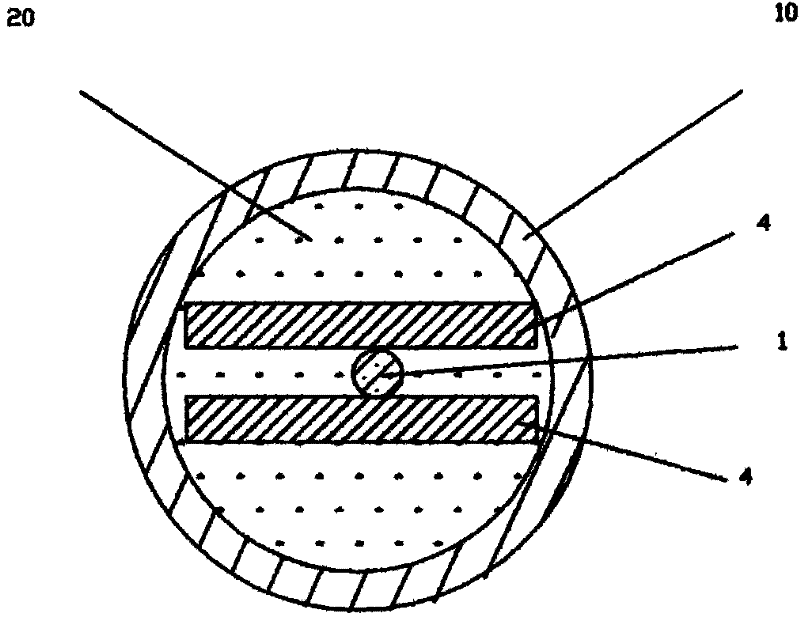

[0026] Such as figure 1 , figure 2 As shown, the present invention includes a toothed plate 4 made of flexible material, and a signal optical fiber 1 is sandwiched between the deformed teeth of the two toothed plates 4 , and the polymer sheath tube 10 wraps the two toothed plates 4 . During actual manufacturing, the void inside the polymer sheath tube is filled with water-blocking material 20 .

[0027] In this embodiment, the polymer sheath tube deforms under external pressure, thereby transmitting the external force to two tooth plates 4 made of flexible materials. Under the action of pressure, the two tooth plates 4 approach each other, and the The deformed teeth on the plate 4 will cause the signal optical fiber 1 to bend and deform, thereby changing the bending loss of the signal optical fiber 1 , thereby realizing the modulation of the light intensity in the signal optical fiber 1 . In this way, the pressure signal is converted into an optical signal and transmitted t...

Embodiment 2

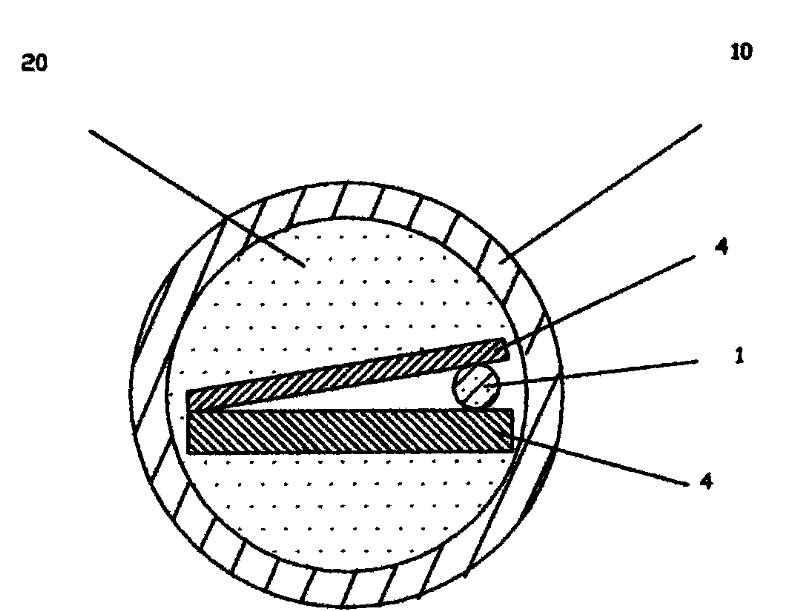

[0030] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is that one side of the two tooth plates 4 is fixed together, which can prevent the pressure-sensitive optical cable from appearing in the processing and use of the two tooth plates 4 The relative movement causes the deformed teeth on the two tooth plates 4 to be unable to correspond alternately; in actual processing and production, the preferred manufacturing method is to make full use of the existing embossing machine of the optical cable manufacturer to make the tooth plates 4. The process is: There is a longitudinal dividing line, and on both sides of the dividing line, the staggered corresponding embossing is rolled out at the same time, and the embossing is the deformed tooth, and then the metal strip is folded in half along the dividing line, and two pieces with one side fixed together can be obtained. The tooth plate 4 can adjust the depth and the pitch of the embossing as required, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com