Backlight unit and display device including the same

A technology of backlight unit and light source group, which is applied in the direction of lighting and heating equipment, mechanical equipment, optical components, etc., and can solve the problems that hinder the reduction of the thickness of liquid crystal display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

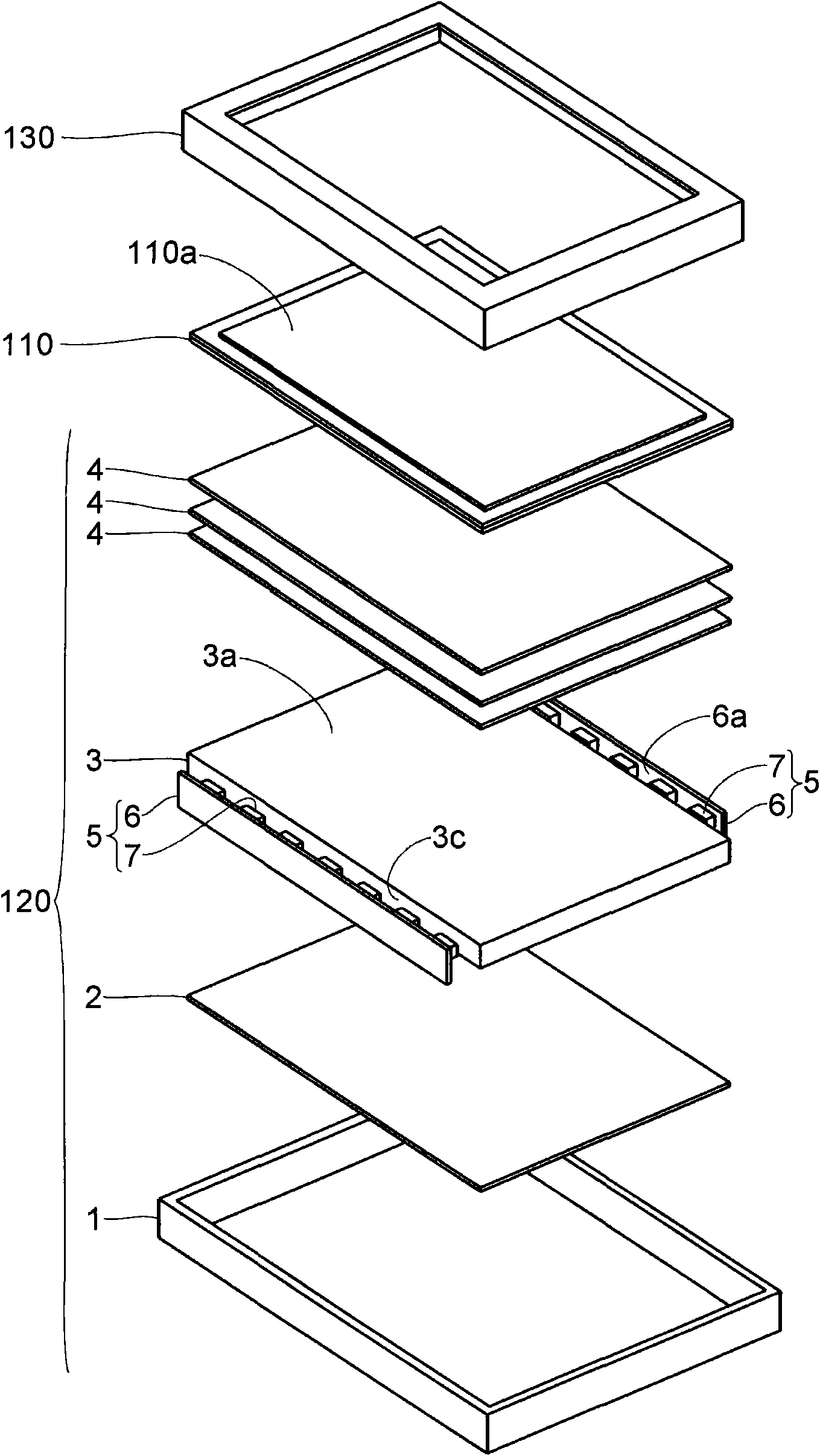

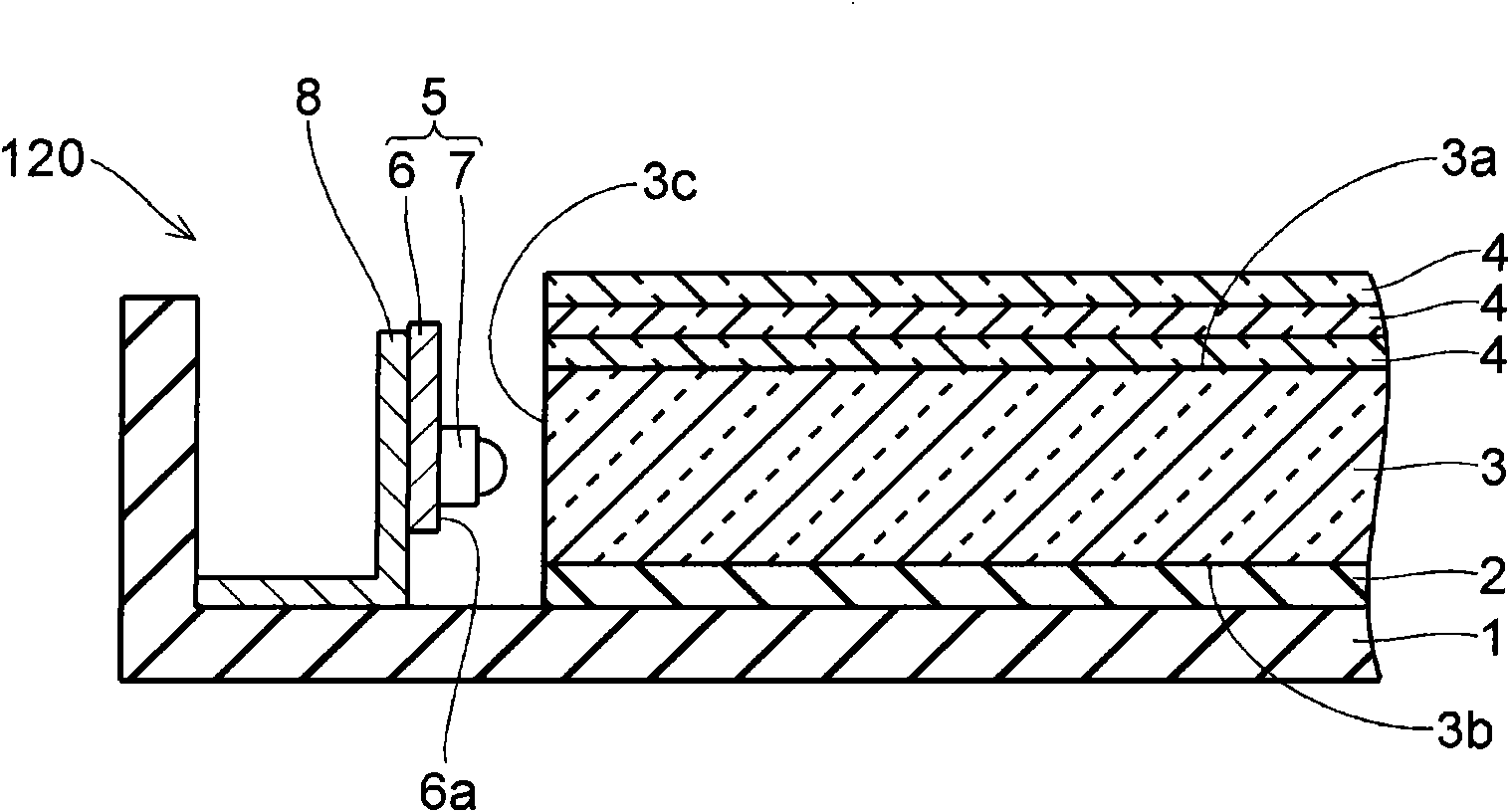

[0054] Refer to the following Figures 1 to 7 A display including the backlight unit according to the first embodiment of the present invention is described.

[0055] Such as figure 1 As shown, the display is a liquid crystal display, and includes at least a liquid crystal display panel 110 having a display surface 110a, and an edge-light type backlight unit placed on the rear surface side of the liquid crystal display panel 110 (the side opposite to the display surface 110a side) 120. When the backlight unit 120 is mounted at an appropriate position on the rear surface side of the liquid crystal display panel 110 , the frame 130 is attached to the same side of the liquid crystal display panel 110 as the display surface 110 a. During a display operation, the backlight unit 120 emits light in a planar manner, and illuminates the rear surface of the liquid crystal display panel 110 with light.

[0056] To describe the specific structure of the display, the liquid crystal dis...

no. 2 example )

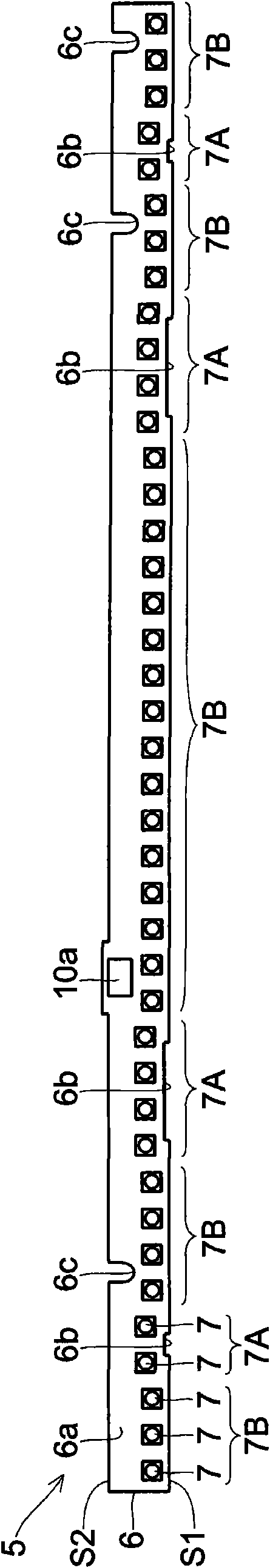

[0084] Refer to the following Figure 10 A description is given of the structure of the light source module installed in the backlight unit according to the second embodiment of the present invention.

[0085] In the second embodiment, as Figure 10 As shown, by setting the mounting density of the LED group 7A higher than that of the LED group 7B, the total luminance of the LED group 7A is made higher than the total luminance of the LED group 7B. Specifically, the gap (pitch) between LEDs 7 adjacent to each other in the longitudinal direction of the printed board 6 in the LED group 7A is narrower than that in the LED group 7B. In the second embodiment, the LEDs 7 belonging to the LED group 7A and the LEDs 7 belonging to the LED group 7B have substantially the same luminous flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com