Supporting stand column for foundation pit and construction method of supporting stand column

A technology of supporting columns and construction methods, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problem of low cost-effective bearing capacity and steel consumption, complex joints of large-diameter steel pipe columns, beam-column joints, and inability to meet multi-channel support Requirements and other issues, to achieve the effect of saving steel and concrete consumption, simple joint method, and low positioning requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

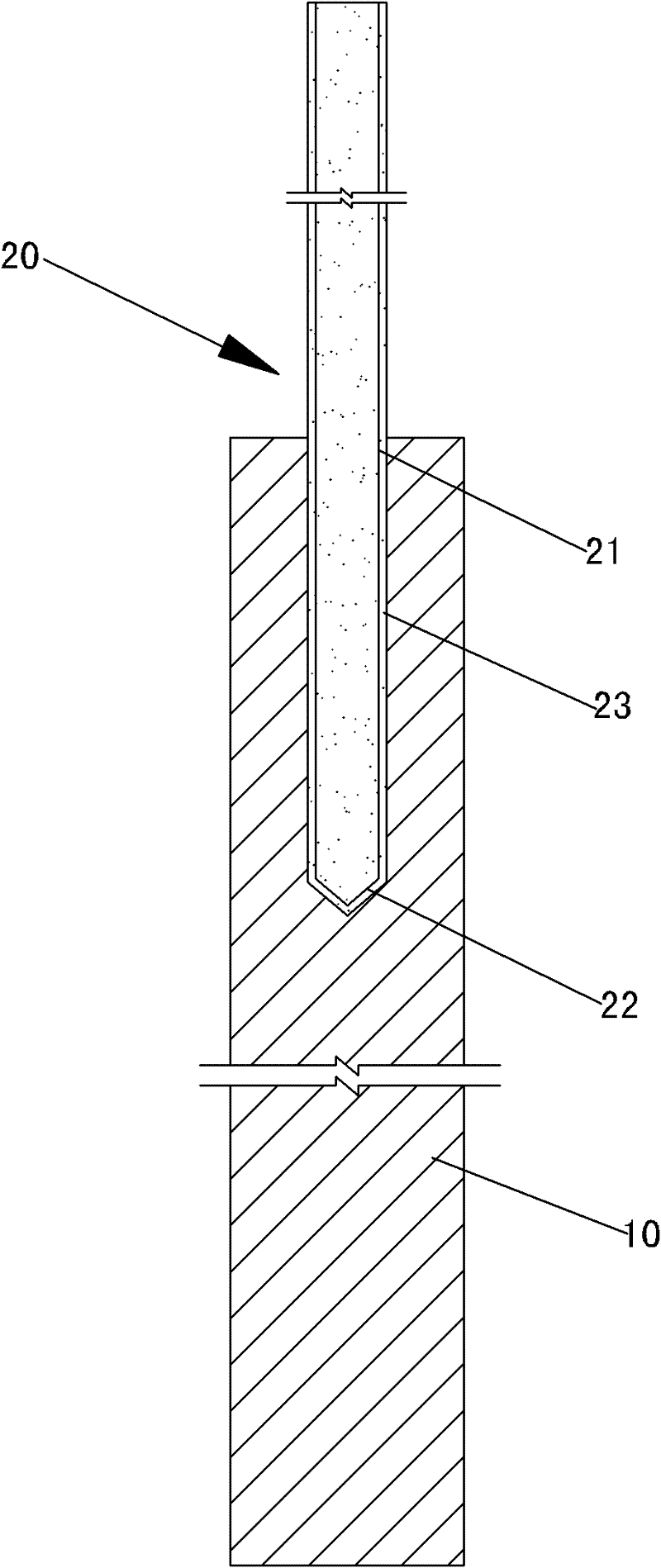

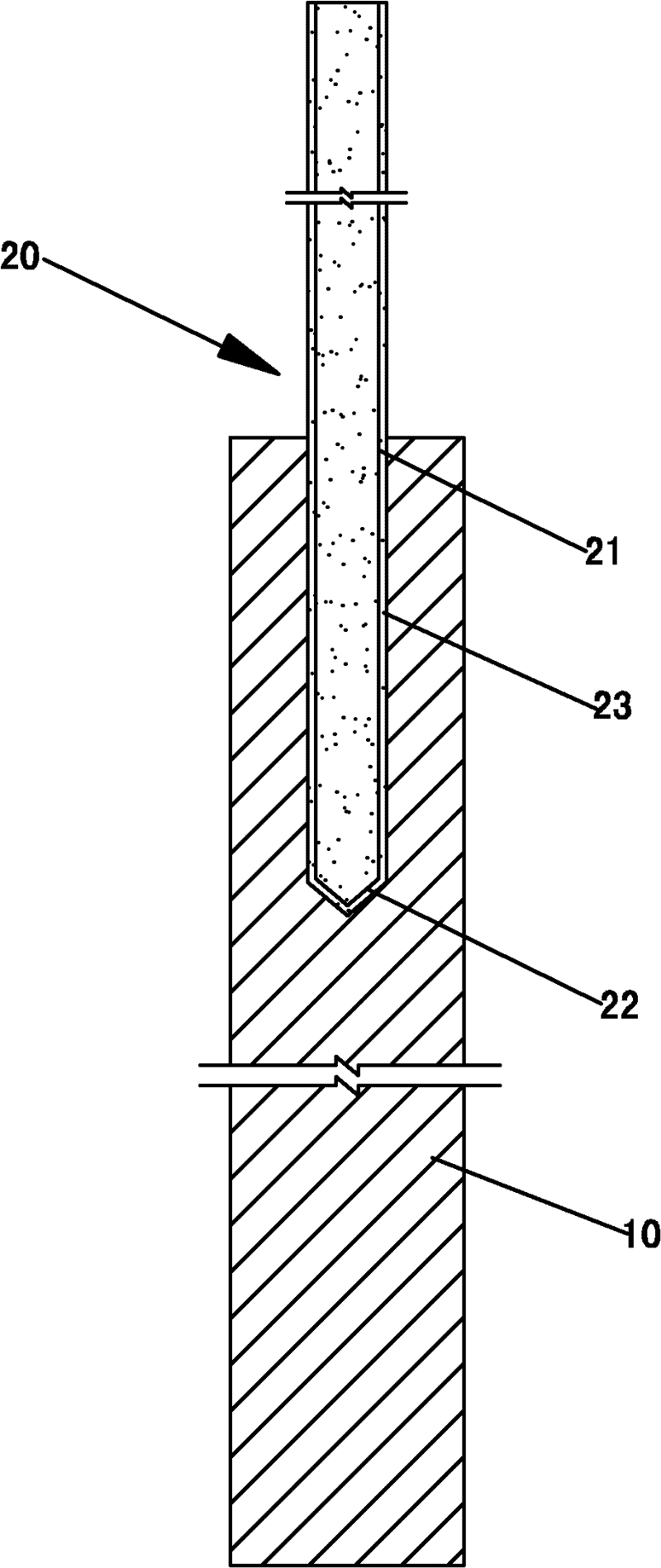

[0030] Please check figure 1 , a support column for a foundation pit, which includes a cast-in-place pile 10 and an insertion portion 20 .

[0031] The cast-in-situ pile 10 is constructed by pouring concrete through drilled steel bars.

[0032] The insertion part 20 includes a steel pipe 21 and a tapered seat 22 . The steel pipe 21 is a circular pipe with an upper port and a lower port. The conical seat 22 has a conical cavity with an opening facing upwards, the conical seat 22 is a conical piece, and the conical cavity is a conical cavity. In this embodiment, the outer diameter and inner diameter of the steel pipe 21 and the maximum outer diameter and maximum inner diameter of the tapered seat 22 are respectively adapted to be equal. The lower port of the steel pipe 21 and the upper port of the conical seat 22 are sealed and fixed together by welding, so that the inner hole of the steel pipe 21 and the conical cavity of the conical seat 22 fit together to form a cavity 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com