Multi-combined fiber shading decorative fabric and preparation method

A technology of combining fibers and fabrics, which is applied in the direction of fabric surface trimming, textile material processing, liquid/gas/vapor textile processing, etc., which can solve the problems of no style appearance, quality guarantee, and shrinkage rate not meeting the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

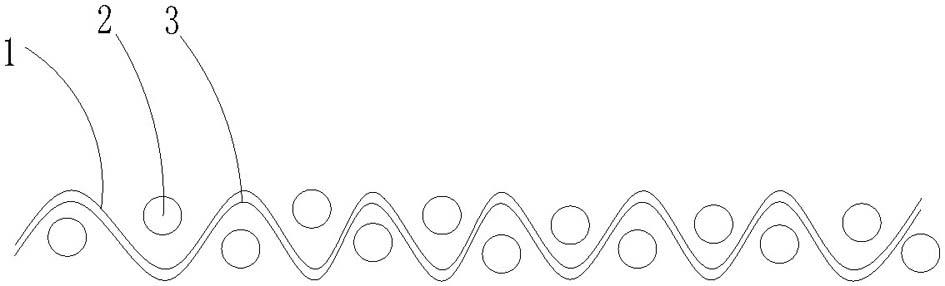

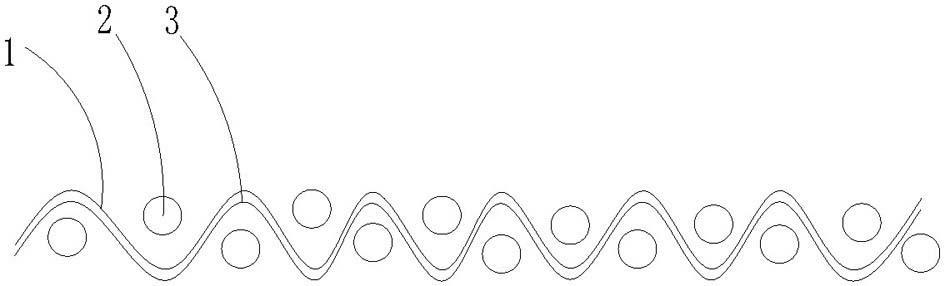

[0067] Example 1: as figure 1 As shown, a multi-combined fiber shading decorative fabric includes a surface layer 1, a middle layer 2 and an inner layer 3. The surface layer 1 is formed by intertwining polyester high-shrinkage filaments and polyester fine-denier filaments. The inner layer Layer 3 is composed of triangular special-shaped bright filaments, the middle layer 2 is polyester black low elastic yarn, the surface layer 1 and the inner layer 3 are wound into warp threads, the middle layer 2 is weft threads, and the warp threads are It is interwoven with the weft thread into a fabric, and its finished product width is 2 meters.

[0068] The surface layer 1 is formed by intertwining 30D / 12F polyester high-shrinkage filament and 75D / 144F polyester fine-denier filament, and the inner layer 3 is composed of 75D / 36F triangular special-shaped bright filament. Layer 2 is made of 300D / 96F polyester black low stretch yarn.

[0069] Described surface layer accounts for the perce...

Embodiment 2

[0093] A multi-combined fiber shading decorative fabric, comprising a surface layer 1, a middle layer 2 and an inner layer 3, the surface layer 1 is formed by intertwining polyester high-shrinkage filaments and polyester fine-denier filaments, and the inner layer 3 is Made of polyester cationic filaments, the middle layer 2 is made of polyester low elastic yarns, the surface layer 1 and the inner layer 3 are wound into warp threads, the middle layer 2 is weft threads, and the warp threads and weft threads are interwoven into a fabric .

[0094] The surface layer 1 is formed by intertwining 30D / 12F polyester high-shrinkage filament and 50D / 72F polyester fine denier filament, the inner layer 3 is composed of 75D / 36F polyester cationic filament, and the middle layer 2 Constructed of 300D / 96F polyester low stretch yarn.

[0095] The weight percentage that described surface layer accounts for fabric is 30.5%, and wherein the weight percentage that polyester high-shrinkage filament...

Embodiment 3

[0119] A multi-combined fiber shading decorative fabric, comprising a surface layer 1, a middle layer 2 and an inner layer 3, the surface layer 1 is formed by intertwining polyester high-shrinkage filaments and polyester fine-denier filaments, and the inner layer 3 is Made of polyester slub filaments, the middle layer 2 is made of polyester black low elastic yarn, the surface layer 1 and the inner layer 3 are wound into warp threads, the middle layer (2) is a weft thread, and the warp threads and The weft threads are interwoven into the fabric.

[0120] The surface layer 1 is formed by intertwining 30D / 12F polyester high-shrinkage filament and 75D / 144F polyester fine-denier filament, the inner layer 3 is composed of 75D / 72F polyester slub filament, and the middle Layer 2 is made of 300D / 96F polyester black low stretch yarn.

[0121] The percentage by weight of the surface layer of the fabric is 36.5%, wherein the percentage by weight of the polyester high-shrinkage filament i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com