Method for preparing micromolecule pectin

A technology of small molecules and pectin, which is applied in the field of high-molecular pectin production technology, and can solve problems such as no control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 5L three-neck flask, stir mechanically, reflux and condense, add 2.4L formic acid (concentration: 1.098g / mL) at room temperature, add 100g of natural orange peel pectin at room temperature under stirring, dissolve, then heat up to 100°C for 10h. After the reaction, concentrate the solvent, add water to dissolve the residue, adjust the pH to neutral, remove insoluble impurities by suction filtration, and then transfer the filtrate to a membrane filter for treatment with cellulose membranes with a molecular weight cut-off of 30,000 and 10,000, and collect 1 to 3 10,000 molecular weight filtrate, the filtrate was concentrated and dried to obtain 26.0 g of a brown solid, with a yield of 26.0%, a PDI value of 1.66, and a galacturonic acid content of 80.9%.

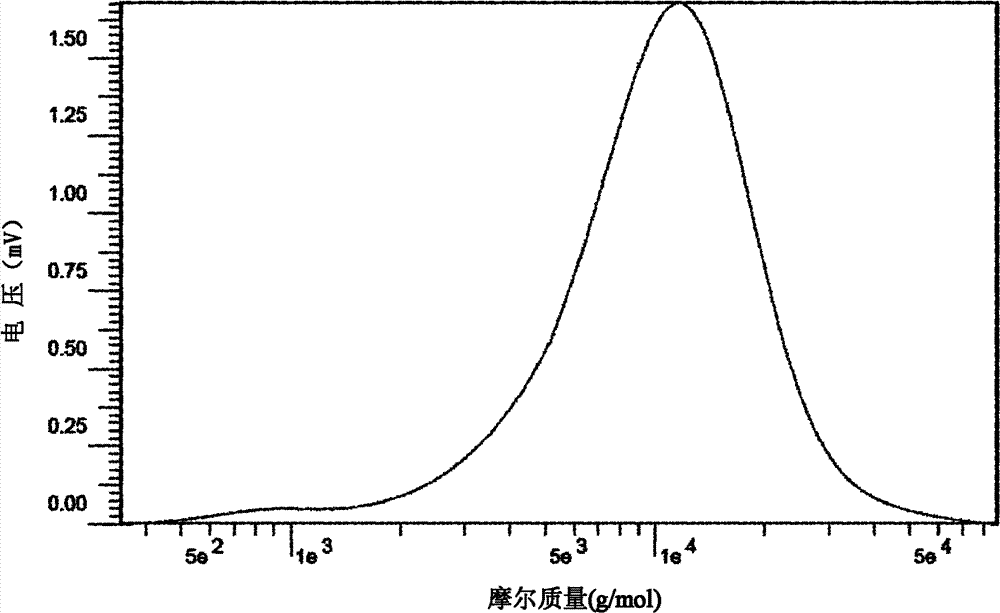

[0037] The GPC collection of illustrative plates of the pectin that embodiment 1 prepares sees figure 1 . The GPC spectrum shows the molecular weight distribution and molecular weight of the polymer substance. The ...

Embodiment 2

[0039] In a 20L three-neck flask, stir mechanically, reflux and condense, add 12L formic acid (concentration: 1.098g / mL) at room temperature, add 500g of natural orange peel pectin in batches under stirring at room temperature, dissolve, and then heat up to 100°C for 18h. After the reaction, concentrate the solvent, add water to dissolve the residue, adjust the pH to neutral, remove insoluble impurities by suction filtration, and then transfer the filtrate to a membrane filter for treatment with cellulose membranes with a molecular weight cut-off of 30,000 and 10,000, and collect 1 to 3 10,000 molecular weight filtrate, the filtrate was concentrated and dried to obtain 150.0 g of a brown solid, with a yield of 30.0%, a PDI value of 1.96, and a galacturonic acid content of 79.9%.

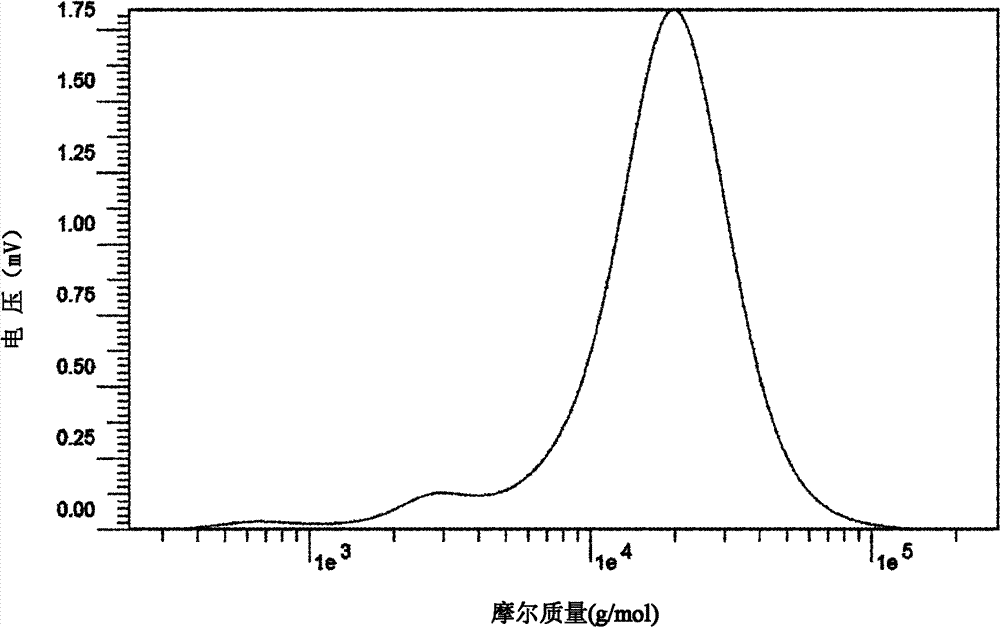

[0040] The GPC collection of illustrative plates of the pectin that embodiment 2 prepares sees figure 2 . The GPC spectrum shows the molecular weight distribution and molecular weight of the polyme...

Embodiment 3

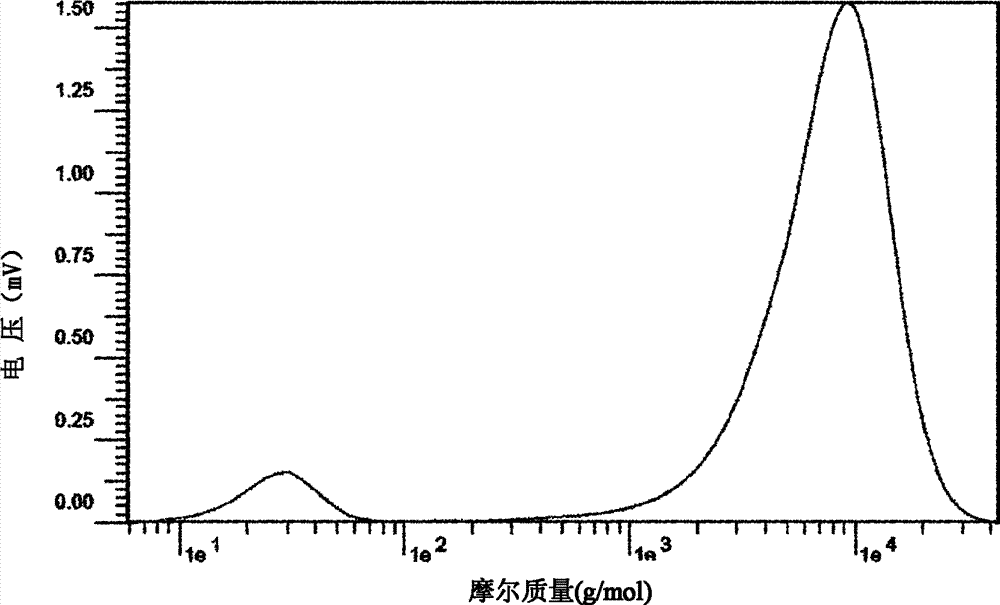

[0042] In a 2L three-neck flask, stir mechanically, reflux and condense, add 1.2L formic acid (concentration: 1.098g / mL) at room temperature, add 50g of natural orange peel pectin at room temperature under stirring, dissolve, then raise the temperature to 100°C for 3 hours. After the reaction, concentrate the solvent, add water to dissolve the residue, adjust the pH to neutral, remove insoluble impurities by suction filtration, and then transfer the filtrate to a membrane filter for treatment with cellulose membranes with a molecular weight cut-off of 30,000 and 10,000, and collect 1 to 3 10,000 molecular weight filtrate, the filtrate was concentrated and dried to obtain 2.7 g of a brown solid, with a yield of 5.4%, a PDI value of 1.81, and a galacturonic acid content of 79.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com