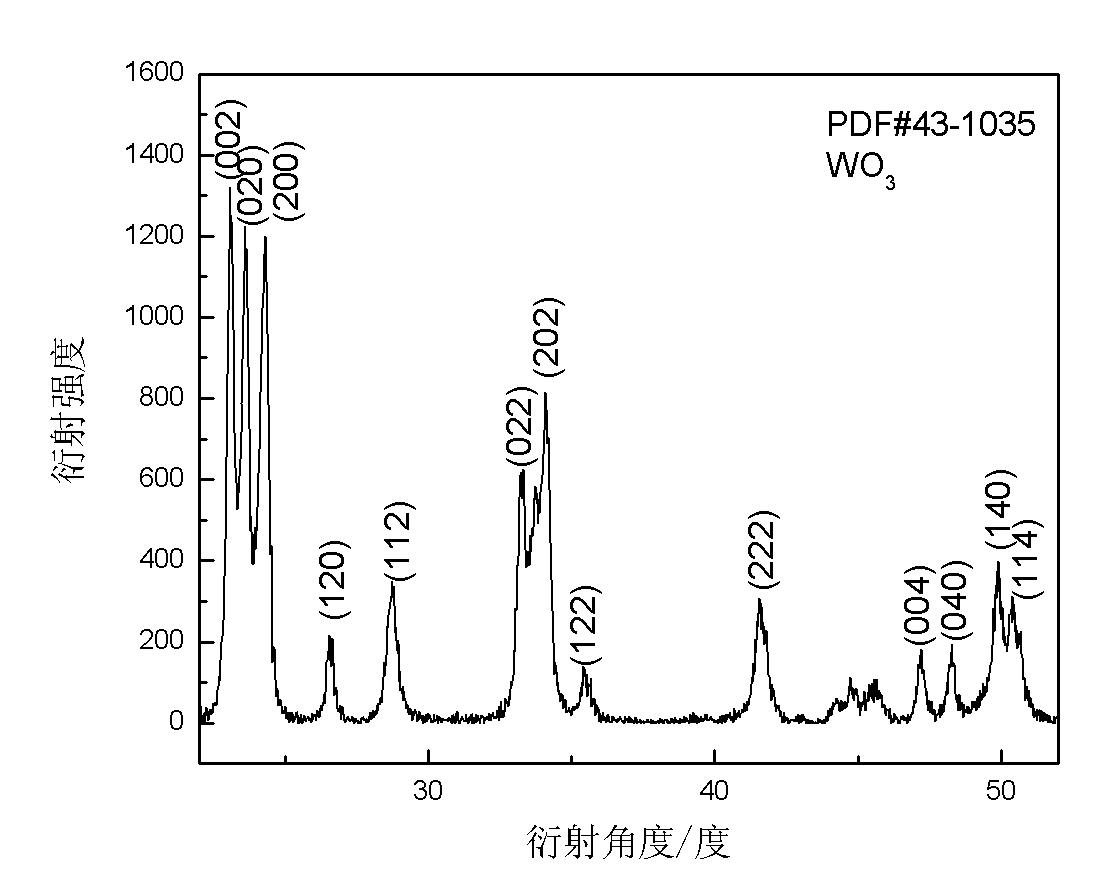

Preparation method of hollow porous tungsten oxide sphere

A tungsten oxide, hollow technology, applied in the direction of tungsten oxide/tungsten hydroxide, etc., can solve the problems of low preparation efficiency, wide particle size distribution, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment, the present invention will be further described.

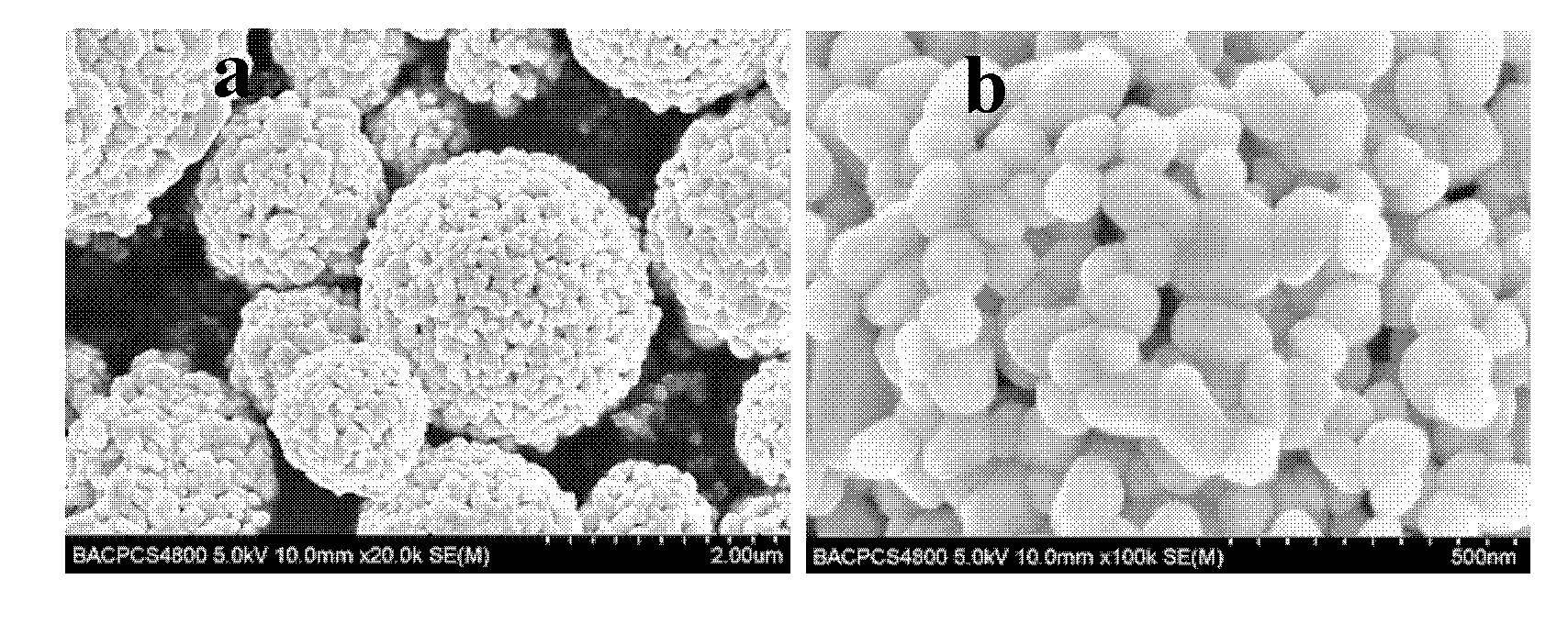

[0015] Select ammonium tungstate as the tungsten source, prepare a certain concentration of aqueous solution (the specific concentration is shown in Table 1), and use the EYELA SD-1000 spray dryer produced in Tokyo, Japan to spray dry. The obtained powder has an inlet temperature of 130 ° C. The outlet temperature is 95°C, and the blast speed is 0.7m 3 / min, spray pressure 100kPa, feed rate 300ml / h, decompose in Hefei Kejing GSL-1600X tube furnace (decomposition temperature and holding time are shown in Table 1) to obtain hollow porous tungsten oxide balls, process parameters and The result is as follows:

[0016] Table 1 Process and results of preparation of hollow porous tungsten spheres by ammonium tungstate

[0017]

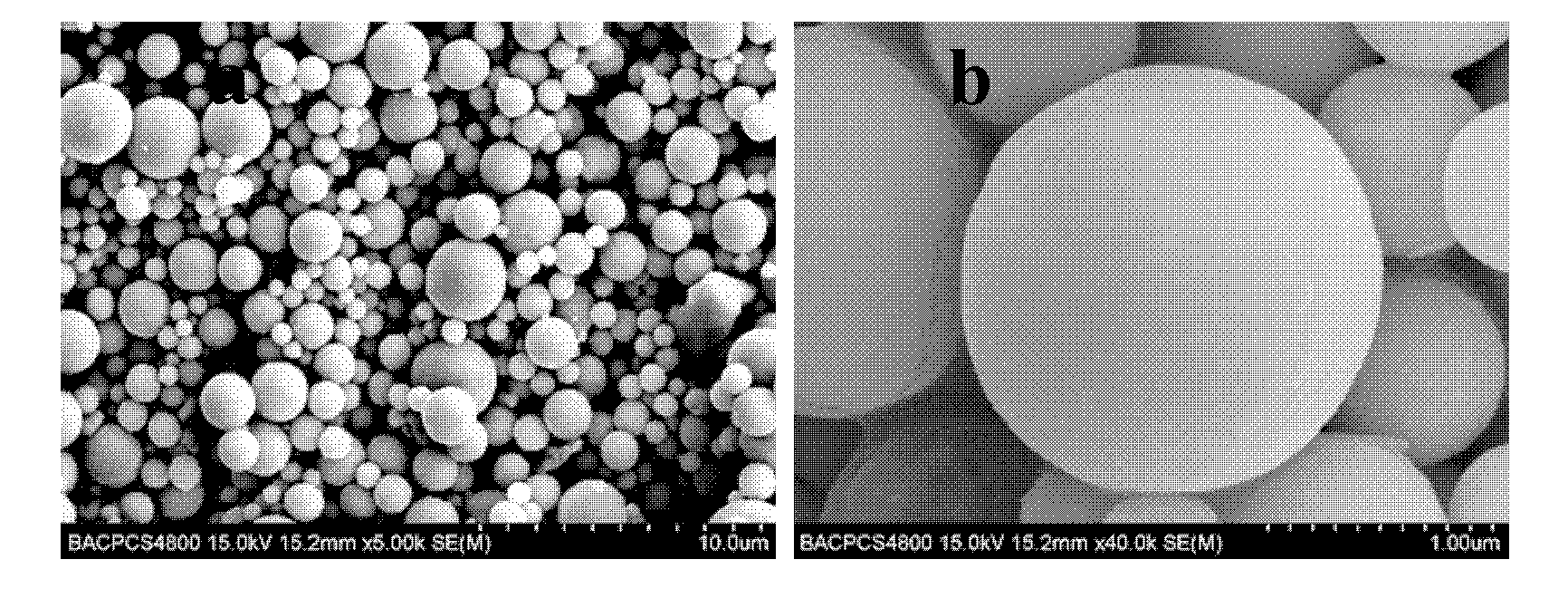

[0018] Select ammonium metatungstate as the tungsten source, configure an aqueous solution of a certain concentration (the specific concentration is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com