Improved copper-clad aluminum wire and preparation method thereof

A copper-clad aluminum strip and an improved technology are applied in the field of composite materials and their preparation, which can solve the problems that the improved copper-clad aluminum strip cannot be produced, the thickness of the electroplated copper layer is limited, the bonding strength is low, and the like, and good promotion value is achieved. and market value, novel preparation method, and the effect of ensuring bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

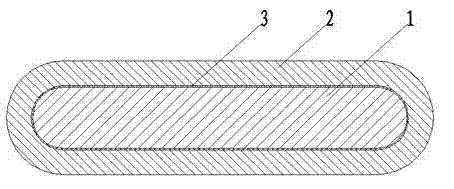

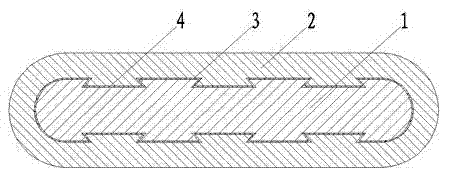

[0024] see figure 2 , an improved copper-clad aluminum row in the present invention, comprising an aluminum row substrate 1 and a copper layer 2, the copper layer 2 is coated on the outer surface of the aluminum row substrate 1; A double metal layer 3 with interatomic metallurgical bonding; the outer surface of the aluminum row substrate 1 is provided with grooves 4 at intervals; the copper layer 2 is embedded in the groove 4 of the aluminum row substrate 1 .

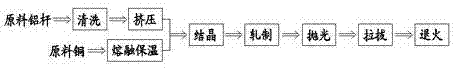

[0025] A kind of preparation method of improved copper-clad aluminum row among the present invention comprises the following steps:

[0026] 1. Cleaning, put the raw aluminum rod into the sodium hydroxide alkaline solution with a temperature of 30 degrees Celsius and soak it for 8 minutes, then clean the oxide and dirt on the surface of the raw aluminum rod, and send the raw aluminum rod to the continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com