Granulating device for sintered ferrite magnet dry pressing

A permanent magnet ferrite, dry pressing forming technology, applied in the direction of solid separation, granulation in static tanks/slots, sieving, etc., can solve the problem of uneven particle size distribution, harsh workplace environment, large workplace dust, etc. problems, to achieve the effect of ensuring the pass rate, preventing agglomeration and accumulation, and ensuring comfort and hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

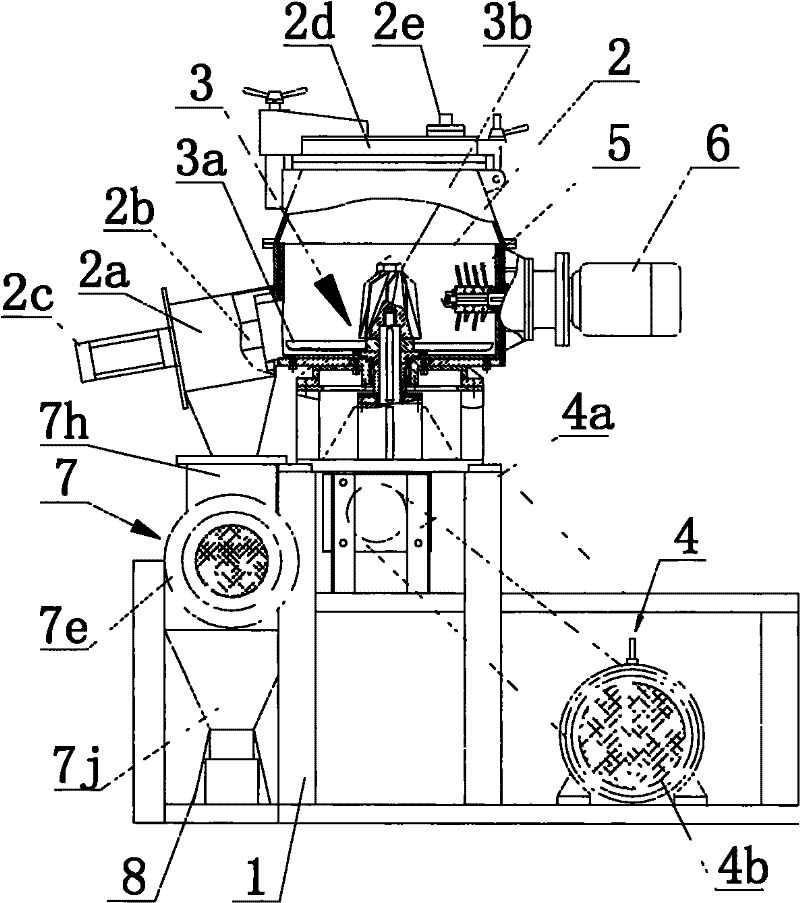

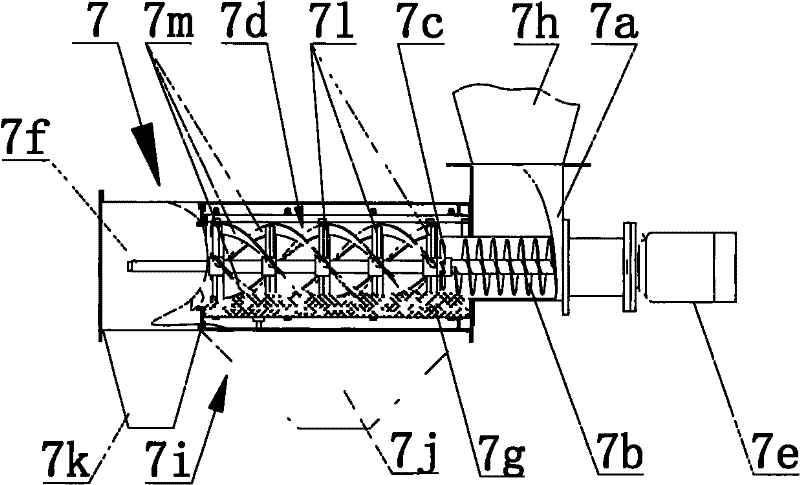

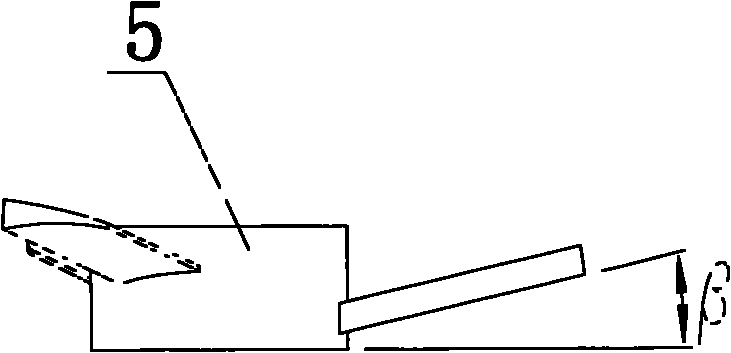

[0022] refer to Figure 1 to Figure 5 As shown, a granulation device for dry pressing of sintered permanent magnet ferrite according to the present invention includes a machine 1, a granulation chamber 2 is provided on the machine 1, and a sealing cover is provided above the granulation chamber 2 The plate 2d is provided with a glue filling port 2e on the sealing cover plate 2d, and a stirring mechanism 3 is provided at the inner bottom of the granulation chamber 2. The stirring mechanism 3 is composed of a coaxially connected mixing paddle 3a and a centrifugal wheel 3b. The centrifugal wheel 3b Set above the mixing paddle 3a; the mixing paddle 3a is composed of three blades with an angle α of 20°-30° to the horizontal plane, and the gap between the blades and the bottom surface of the granulation chamber 2 is 1-3mm; the mixing paddle 3a A centrifugal wheel 3b is provided above to prevent the accumulation of the intermediate magnetic powder. The centrifugal wheel 3b consists o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com