Parallel structure of voltage source type PWM (Pulse Width Modulation) rectifier and control method of the rectifier

A technology of voltage source type and control method, which is applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., and can solve problems such as harm, system performance degradation, and normal operation of rectifiers. The problem of current sharing and the effect of avoiding circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

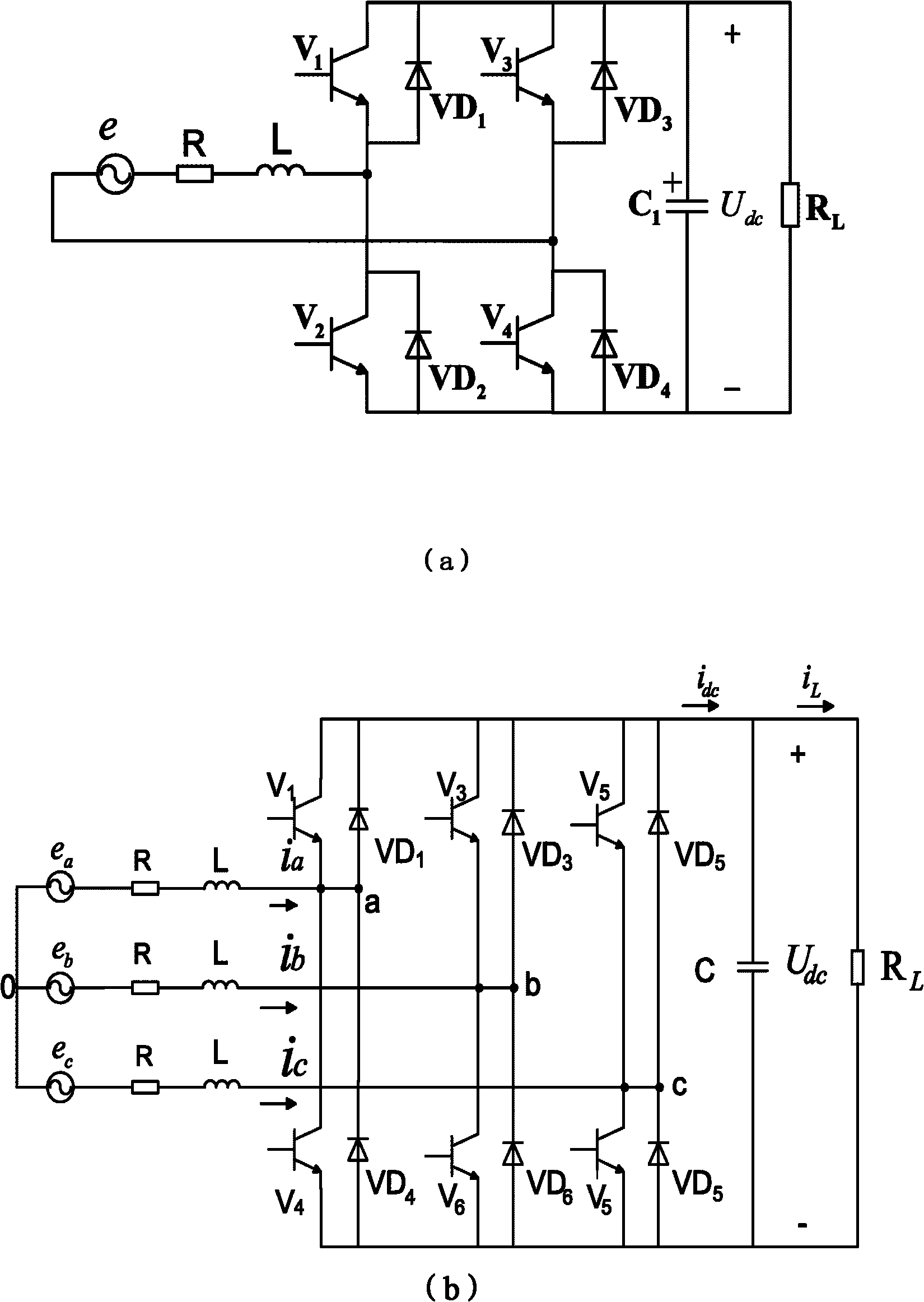

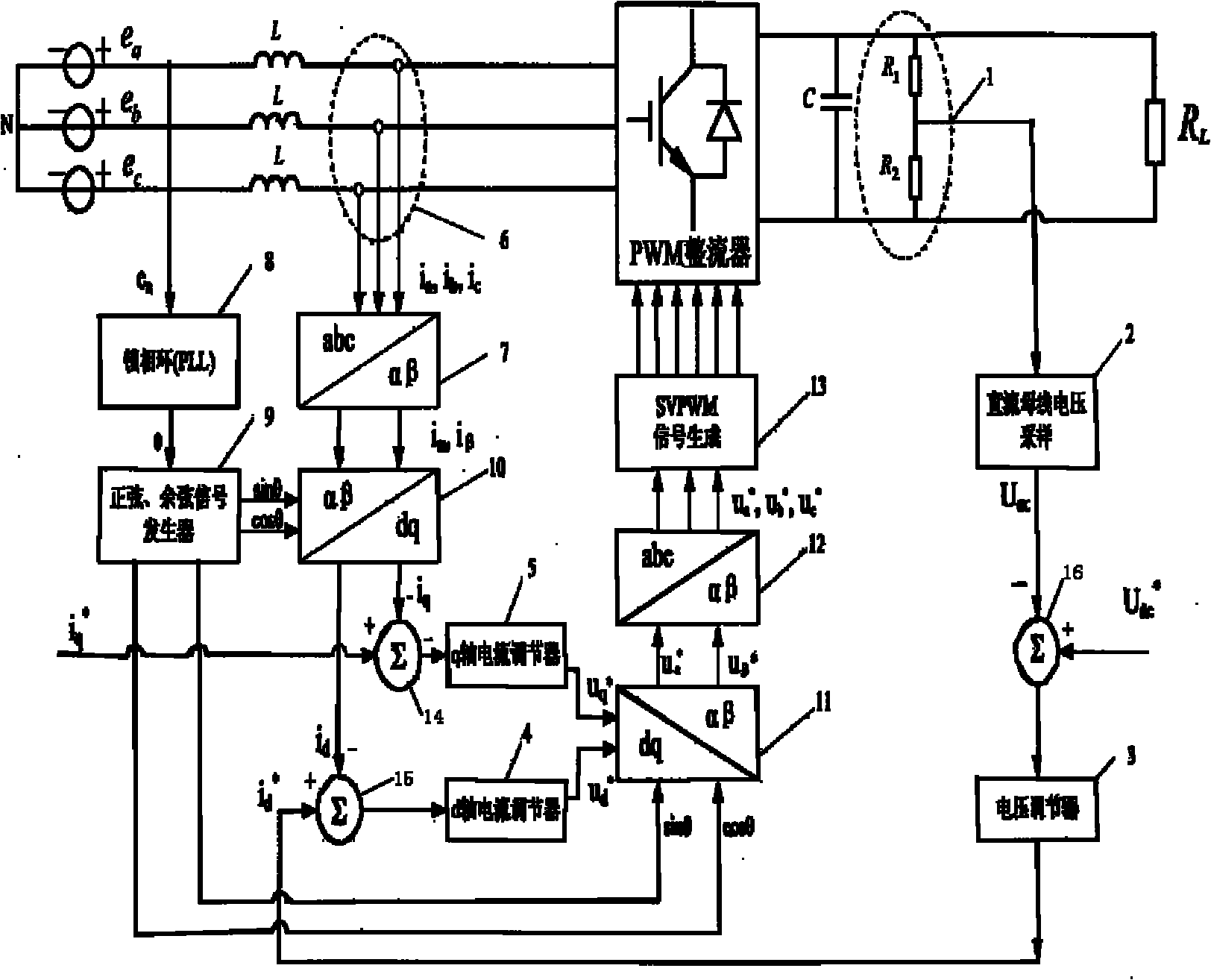

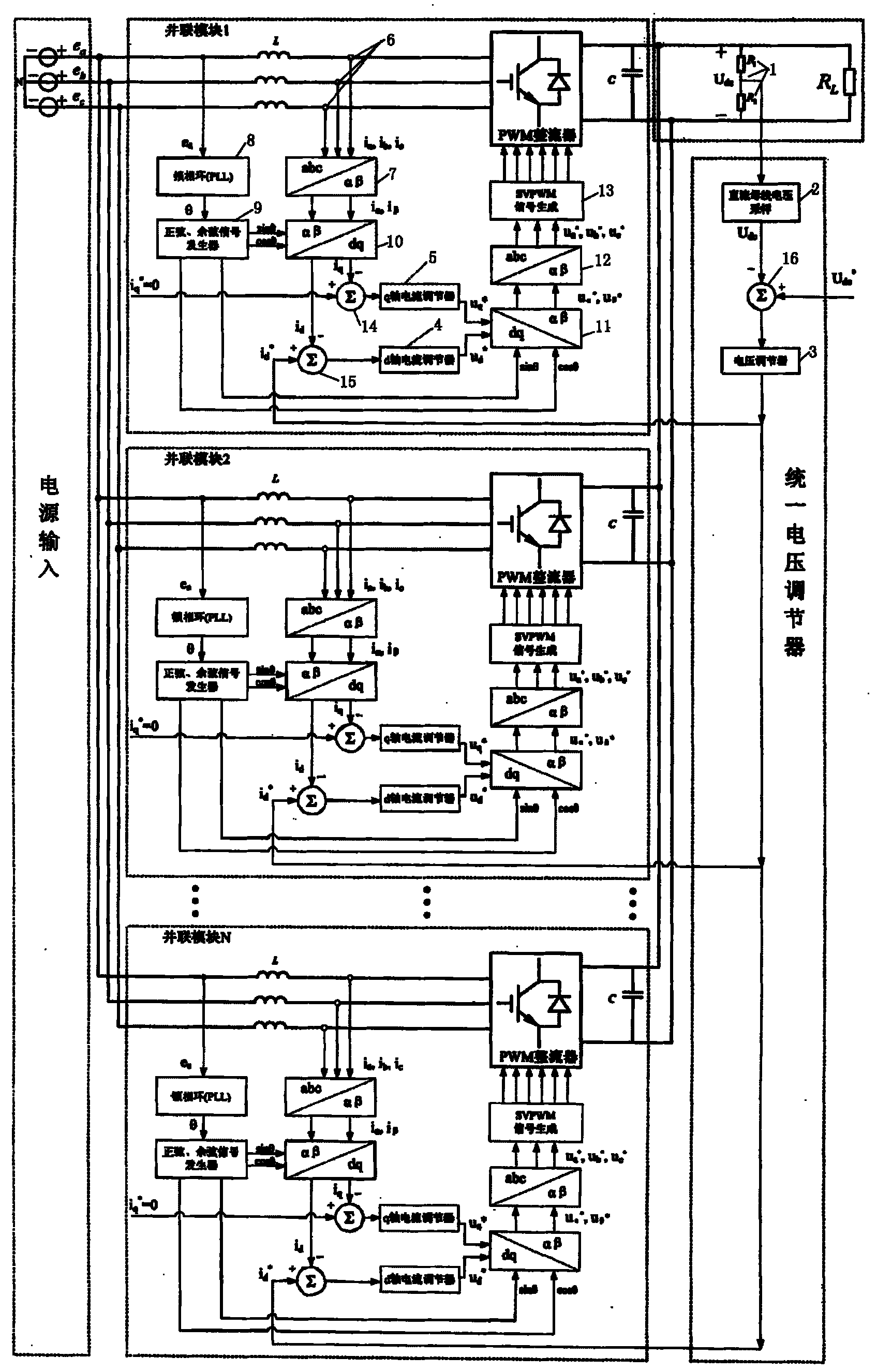

[0019] The logical relationship of its control is as follows image 3 shown. The detailed description is as follows: The electrical topology of the main circuit is divided into parallel connection of single-phase voltage source PWM rectifiers, parallel connection of three-phase voltage source PWM rectifiers, and parallel structure of multi-module three-phase voltage source PWM rectifiers. Typical voltage source PWM Rectifier topologies such as figure 1 (a), (b) shown. The main circuit uses power switch tubes with anti-parallel diodes to form the upper (or lower) arm, and the upper and lower arms are connected in series to form a bridge arm; two bridge arms are connected in parallel to form a single-phase bridge circuit such as figure 1 (a), three bridge arms are connected in parallel to form a three-phase bridge circuit such as figure 1 (b).

[0020] The parallel structure of the single-phase voltage source type PWM rectifier means that the main circuit is composed of an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com