High-illumination LED (light emitting diode) lamp bulb with 360-degree full fire angle

A technology of LED light bulbs and high illuminance, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve problems such as fragile, high cost, and inconsistent with environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

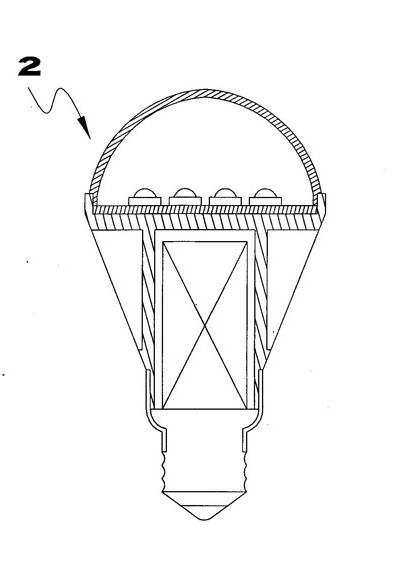

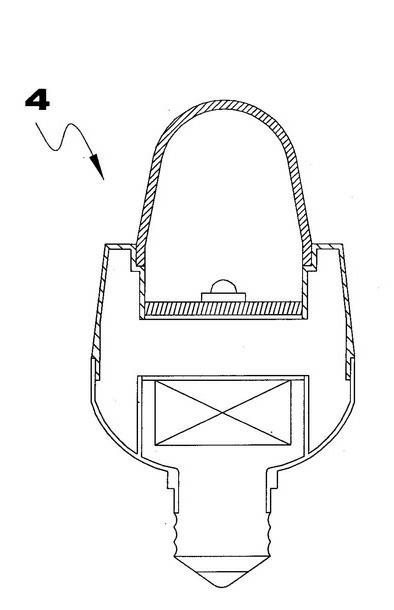

[0046] as attached Figure 5 As shown, the first preferred embodiment of the high-illuminance LED light bulb 1 with a 360° total incidence angle of the present invention: the light bulb 1 includes a light-transmitting lamp holder 11, a light-transmitting lampshade 12, a light-transmitting support plate 112, a The radiator 153 , a first light emitting module 13 and a second light emitting module 14 . The light-transmitting lamp holder 11 includes a lower end 119 and an upper end 114 . The lower end 119 of the light-transmitting lamp holder 11 is mounted with a lamp cap 10 . The upper end 114 of the light-transmitting lamp holder 11 forms an opening 19 . The transparent lampshade 12 is combined with the upper end 114 of the transparent lamp holder 11 and closes the opening 19 so that the transparent lamp holder 11 and the transparent lampshade 12 jointly define a chamber 110, and a driver 17 is installed inside the chamber 110 A step 111 is provided around the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com