Valve with bellows seal

A bellows and valve technology, applied in shaft seals, valve details, valve devices, etc., can solve the problems of small wall thickness of bellows, great difference in thickness, and failure of bellows seals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

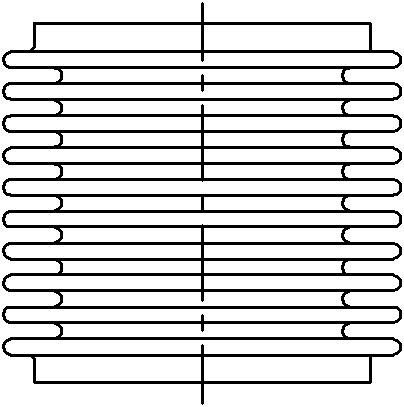

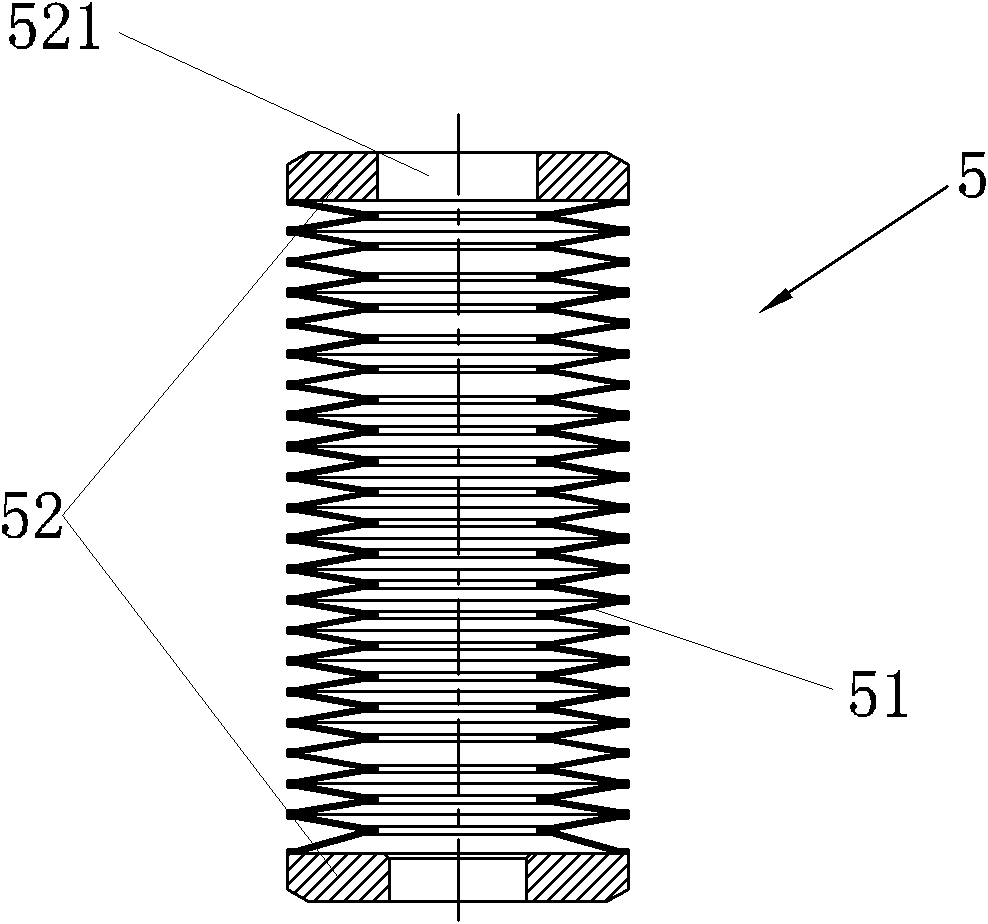

[0016] Such as figure 2 , 3 , 4, this embodiment includes a valve body 1, and a valve cover 2 installed on the valve body 1, a valve disc 3, a valve stem 4, a bellows 5 and a driving mechanism 6, and the valve body 1 is provided with a valve Cavity 11, the first fluid passage 111 and the second fluid passage 112 leading to the valve chamber 11 respectively, and the valve stem installation passage 12 leading to the inner and outer spaces of the valve chamber 11 and for installing the valve stem 4, the valve disc 3 is located at the first A fluid channel 111 and a second fluid channel 112 constitute the opening and closing of the valve cavity 11. The valve cover 2 is provided with a valve stem installation hole 21 for the valve stem 4 to pass through. The valve cover 2 is fixed on the valve stem for installation. At the opening end of the channel 12, one end of the valve stem 4 is linked with the valve disc 3, and the other end is linked with the driving mechanism 6. The bello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com