Middle modulus poly (p-phenyl-terephthalamide) fiber and preparation method thereof

A technology of poly-p-phenylene terephthalamide and p-phenylene phthalamide, which is applied in the field of medium modulus poly-p-phenylene terephthalamide fiber and its preparation, and can solve the problem of affecting industrial efficiency , Difficult fiber technology and other issues, to achieve a wide range of applications, high efficiency, and fill the gaps in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

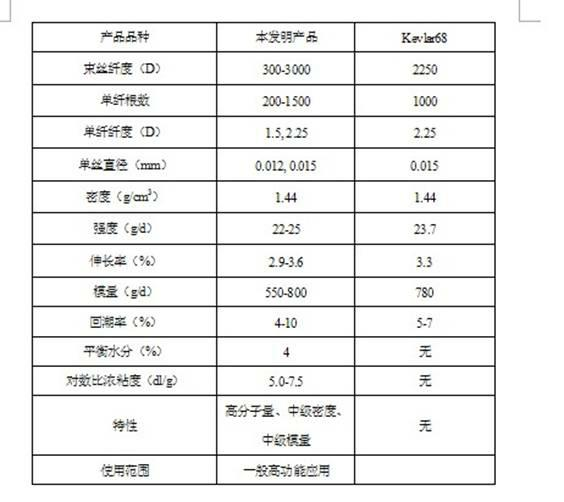

[0046] Adopt the method described in "Application No. 200910216761.X" to make general fibers, and the specific scheme of its polymerization and spinning process is as follows:

[0047] The poly-p-phenylene terephthalamide (PPTA) polymer is synthesized by a low-temperature solution polycondensation method as raw materials, as follows:

[0048] A. Polymerization raw materials include:

[0049] p-phenylene diamine [PPD],

[0050] Terephthaloyl chloride [TPC],

[0051] The solvent is (N-methyl pyrrolidone) [NMP],

[0052] Polymerization-assisting salt (i.e. co-solvent) is calcium chloride (CaCl 2 );

[0053] Where: the molar ratio of PPD / TPC is equal to 1.0, CaCl 2 The molar ratio of / PPD is equal to 1.4, and the solid content of the polymerization mixture is 11%;

[0054] B. Polymerization method:

[0055] Pass nitrogen into the oven after drying, then add dry NMP / CaCl 2 Solvent and dry high-purity p-phenylenediamine (PPD), turn the agitator, mix well, start the chilled w...

Embodiment 2

[0062] The polymerization and spinning process for this example was the same as that described in Example 1, but with wet yarn stretching prior to drying in the spinning step.

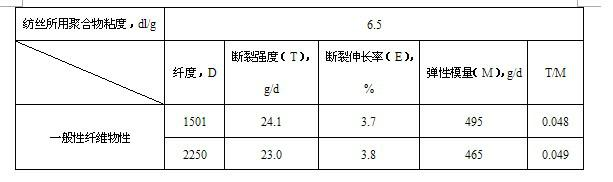

[0063] In this embodiment, wet yarn stretching is mainly carried out before the drying process, that is, by adjusting V 6 / V 5 Ratio to achieve stretching. through different V 6 / V 5 Ratio, the obtained fiber properties are shown in Table 3.

[0064] Table 3 Mechanical properties of fibers subjected to wet yarn micro-stretching before drying

[0065]

[0066] The above data clearly indicate that stepwise wet yarn stretching during washing and drying increases fiber strength and modulus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com