Method for intensifying Cr-Mo alloy cast iron thin-wall cylinder liner

A technology of alloy cast iron and cylinder liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail:

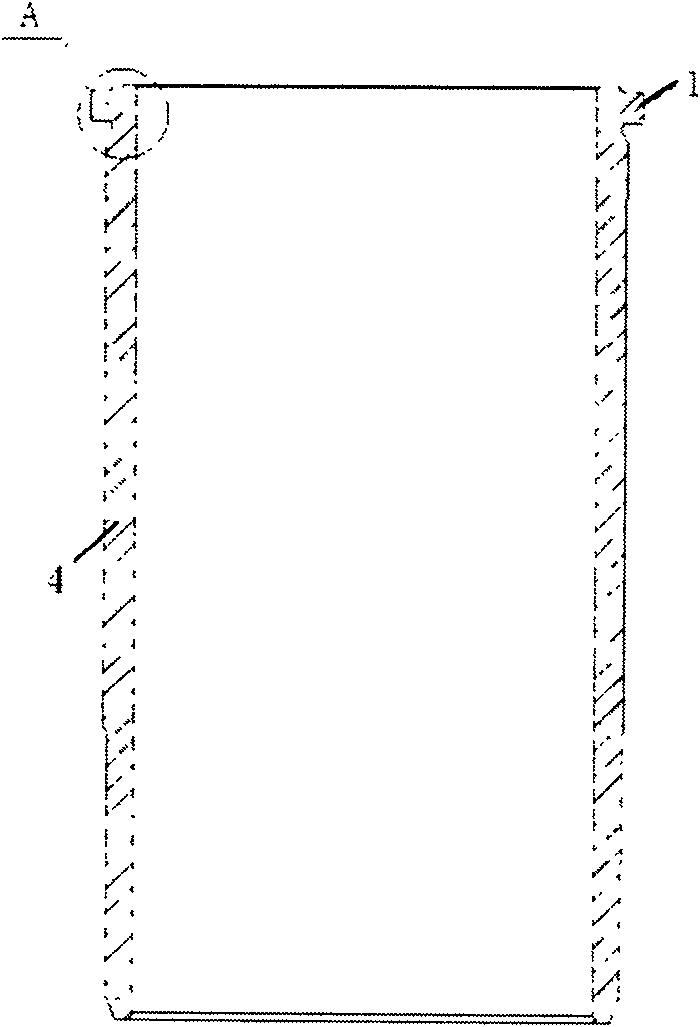

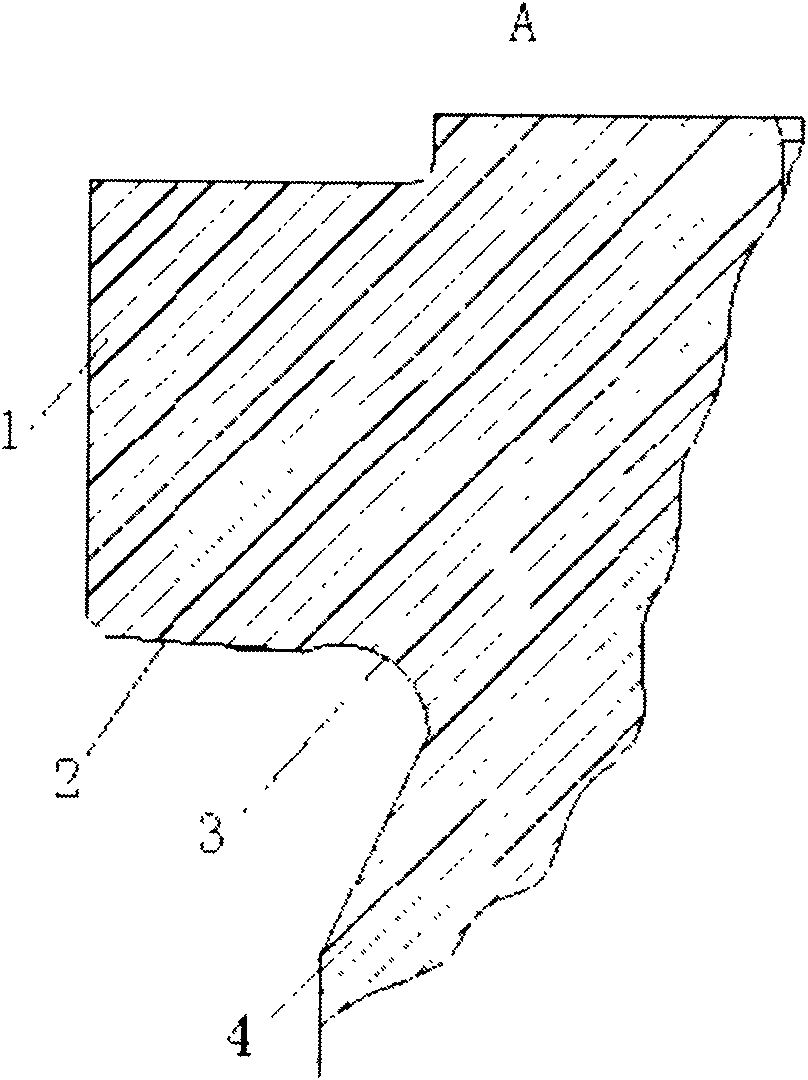

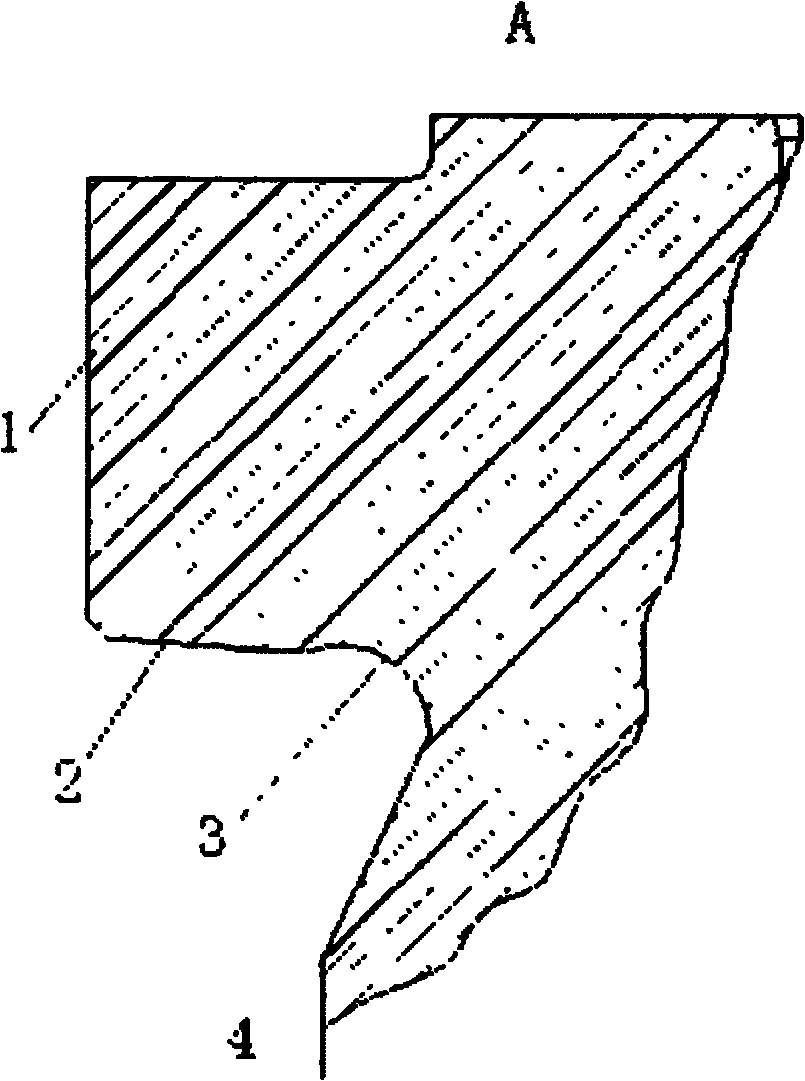

[0015] A method for strengthening the Cr-Mo alloy cast iron thin-walled cylinder liner. Centrifugally cast a cylinder liner blank with a flange 1 matching the box body. The cylinder liner blank is machined, and the lower end surface of the flange is machined outward. The upward bearing surface 2 with a 5′ cone angle to the horizontal plane is used for the transition fillet 3 of the cylinder liner by special rolling equipment. The rolling force is locally strengthened for rolling.

[0016] Another embodiment of the strengthening method of a Cr-Mo alloy cast iron thin-walled cylinder liner. The lower end surface of the flange is processed to form an outward and upward support surface 2 with a cone angle of 20' with the horizontal plane, and the cylinder is aligned by special rolling equipment. Set of transition fillets with 3 uses The rolling force is locally strengthened for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com