Compound type thickening agent applicable to common wet-mixed mortar

A wet-mixed mortar and composite technology, which is applied in the field of building materials, can solve the problems of low strength, poor water retention, and few types of thickeners, and achieve the effects of good working performance, meeting construction requirements, and good compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

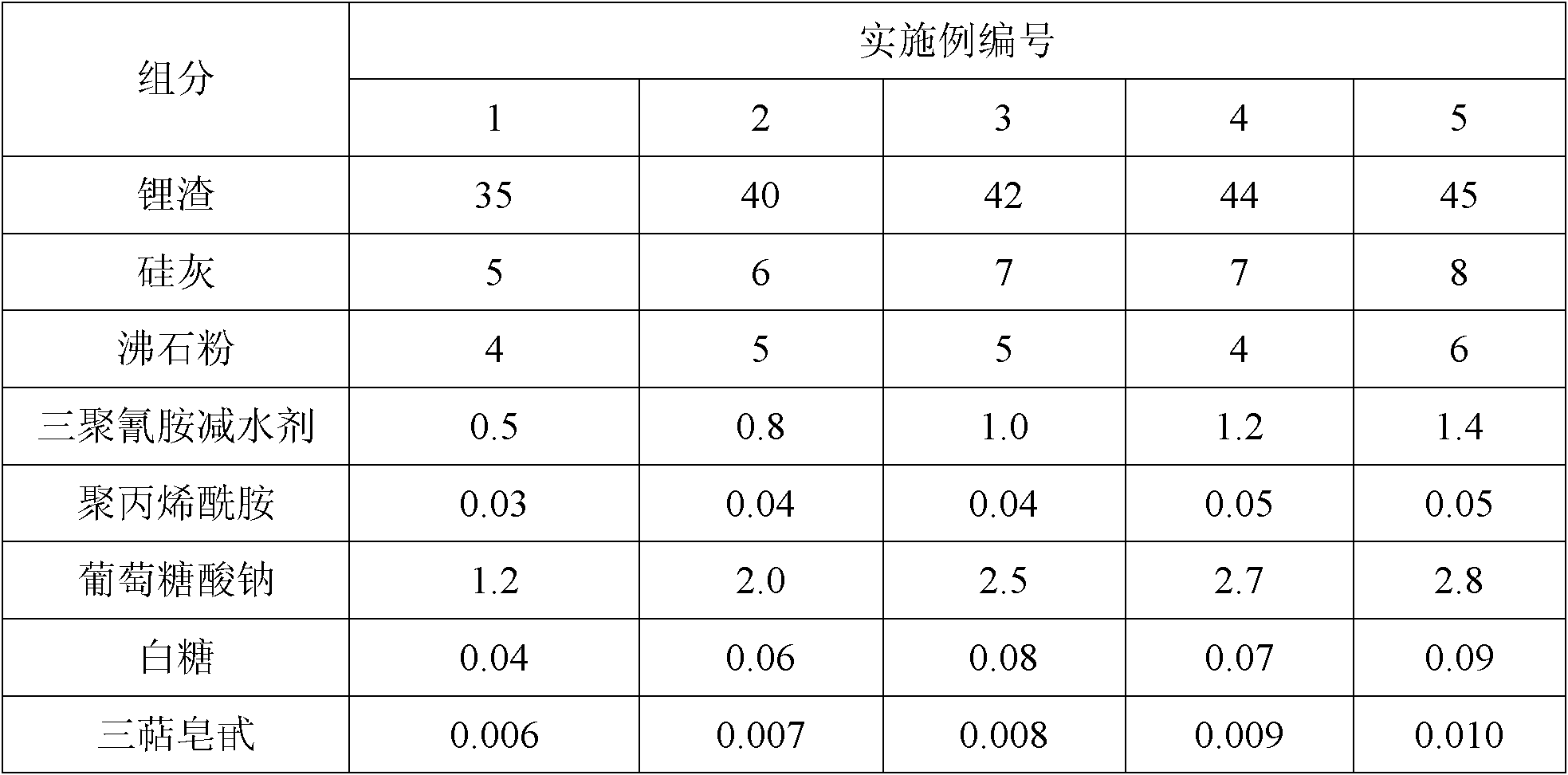

[0030] The raw materials and formulations of Examples 1-5 are as shown in Table 1.

[0031] Table 1, Composite thickener formulation table suitable for ordinary wet-mixed mortar (mass parts)

[0032]

[0033] The lithium slag is light yellow powder with a specific surface area of 420m 2 / kg.

[0034] The silica fume described is densified micro-silica fume, gray, with a specific surface area of 200,000 cm 2 / g.

[0035] The zeolite powder is in the form of a light yellow powder, with 11.2% remaining on an 80 μm square hole sieve.

[0036] The melamine water reducer is white powder, easily soluble in water, with a water content of 1.2% and a water reducing rate of 19.2%.

[0037] The polyacrylamide is white powder, non-ionic, easily soluble in water, and has a molecular weight of 8 million.

[0038] The sodium gluconate is light yellow powdery solid, easily soluble in water, with a water content of 0.5%.

[0039] The white sugar is edible white sugar with a sucrose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com