Composite fiber band and production process

A composite fiber and fiber filament technology, applied in the direction of synthetic resin layered products, layered products, flexible slender elements, etc., can solve the problems of low tensile strength, short service life, damage to goods by loose packaging, etc. High, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mixture comprises 80% to 85% by weight of polypropylene, 0.5% to 10% by weight of short fibers, 12% to 70% by weight of long fibers, and 0 to 10% by weight of ‰ of antioxidant and 0-10‰ of anti-ultraviolet agent. Of course, the mixture may also include polyethylene in an amount of 0-20% by weight. Specifically: including 80% by weight of polypropylene, 5% by weight of short fibers, 14% by weight of long fibers, 5% by weight of antioxidants and 5% by weight anti-ultraviolet agent. Of course, the fiber filaments can also be twisted. Wherein, the length of the short-cut fibers is 0.09-1.5 mm. The short cut fibers are nylon fibers, polyester fibers, glass fibers, plant fibers or any combination thereof. The long fibers are nylon fibers, polyester fibers, plant fibers or any combination thereof.

Embodiment 2

[0027] In the composite fiber tape of the present invention, the mixture comprises 40% to 80% by weight of polypropylene, 0 to 20% by weight of polyethylene, and 1 to 40% by weight of polyolefin elastomer , 0.5%-10% by weight of short fibers, 12%-70% by weight of long fibers, 0-10% by weight of antioxidants and 0-10% by weight of anti-ultraviolet agents . Specifically: including 49% by weight of polypropylene, 10% by weight of polyethylene, 20% by weight of polyolefin elastomer, 5% by weight of short fibers, and 5% by weight of short fibers. 15% long fiber, 5% by weight of antioxidant and 5% by weight of anti-ultraviolet agent. Of course, the fiber filaments can also be twisted. Wherein, the length of the short-cut fibers is 0.09-1.5 mm. The short cut fibers are nylon fibers, polyester fibers, glass fibers, plant fibers or any combination thereof. The long fibers are nylon fibers, polyester fibers, plant fibers or any combination thereof.

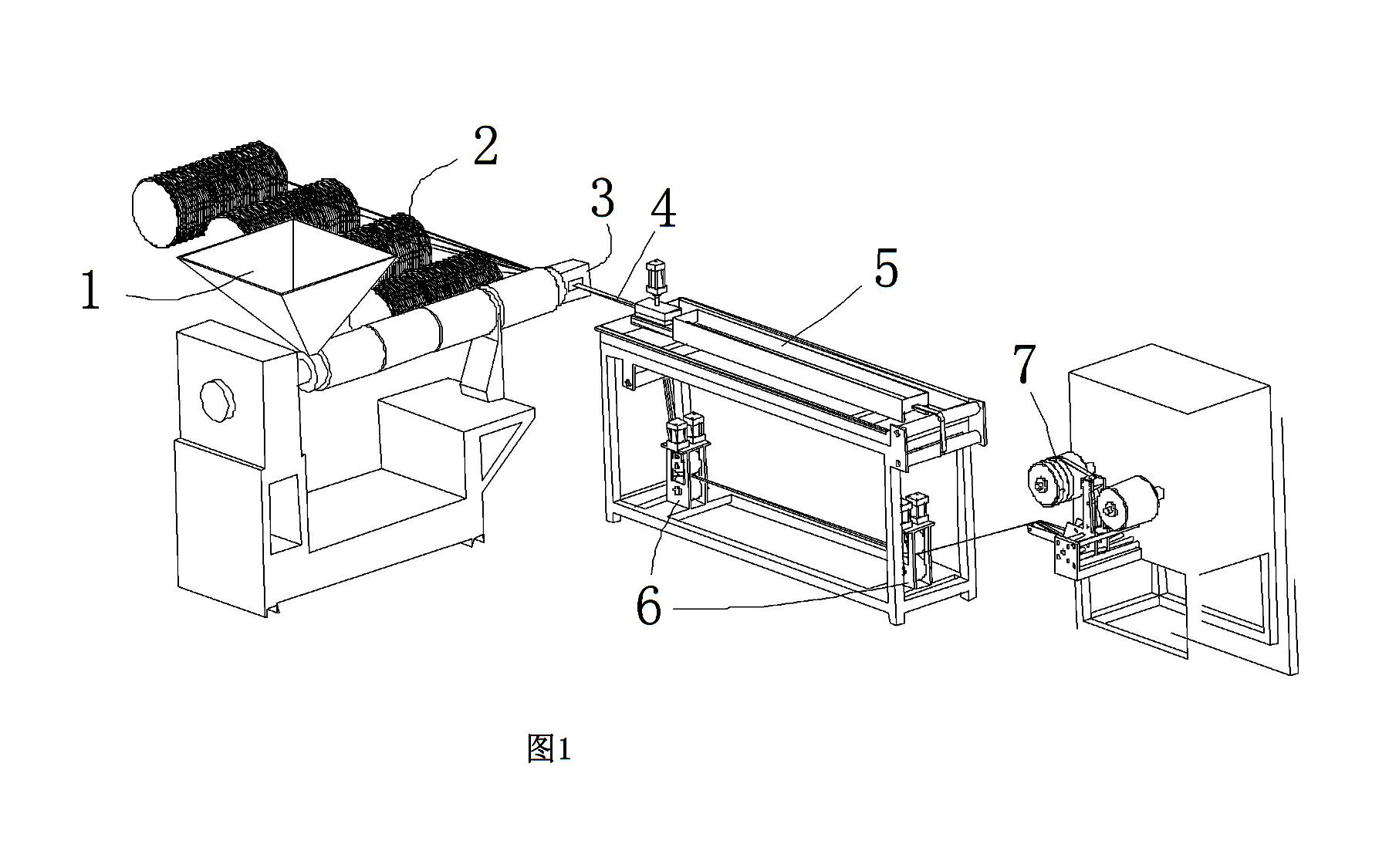

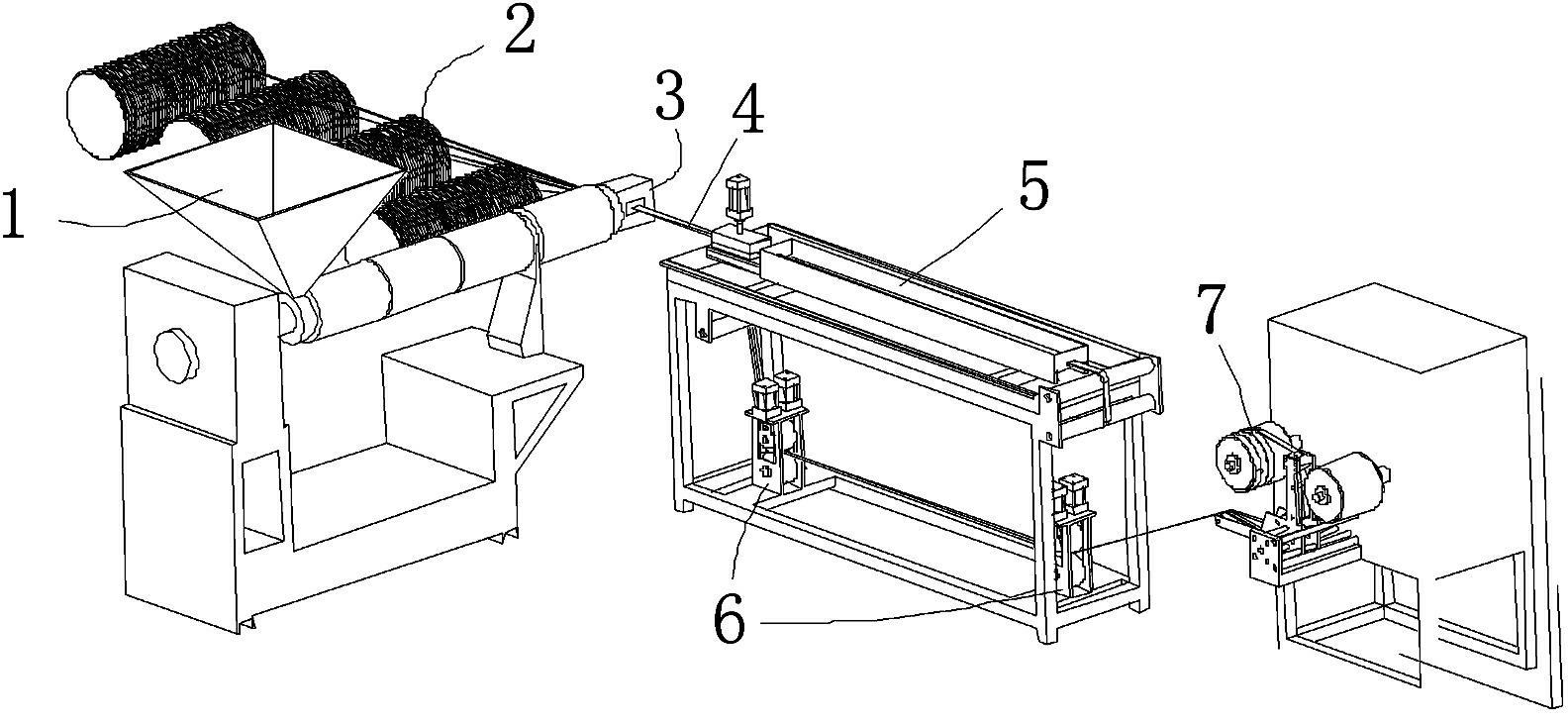

[0028] Such as figure 1 Shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com