Grinding head device for grinding silicon core or other crystalline materials

A crystalline material and a technology for grinding silicon cores, which are used in grinding machine parts, grinding/polishing equipment, metal processing equipment, etc., and can solve problems such as inability to locate in the left and right directions, poor polysilicon quality, and large lap resistance. , to avoid uneven processing quality, improve grinding surface quality, and uniformly grind silicon cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention can be explained in more detail with reference to the following examples, but the present invention is not limited to the combination of these examples.

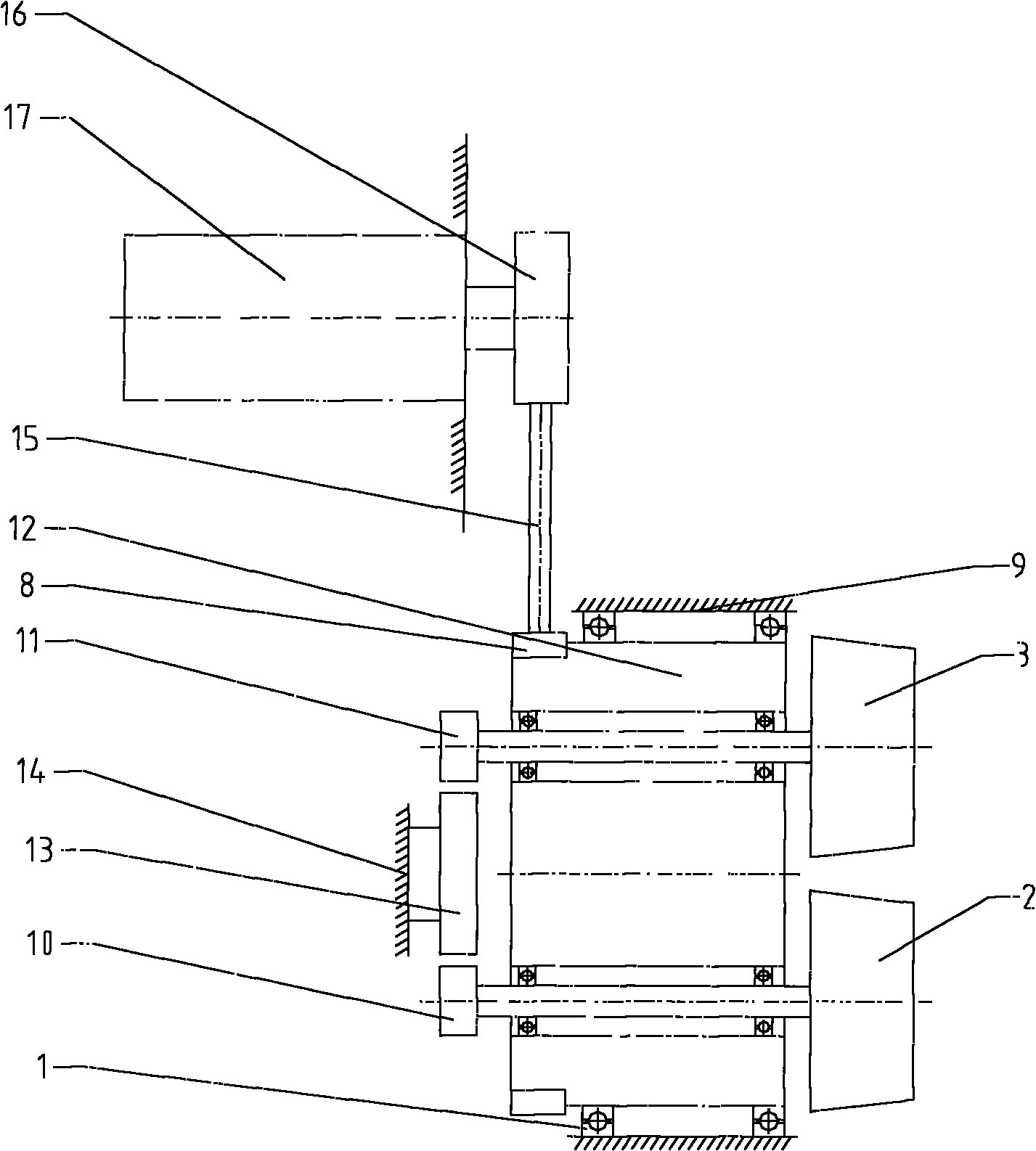

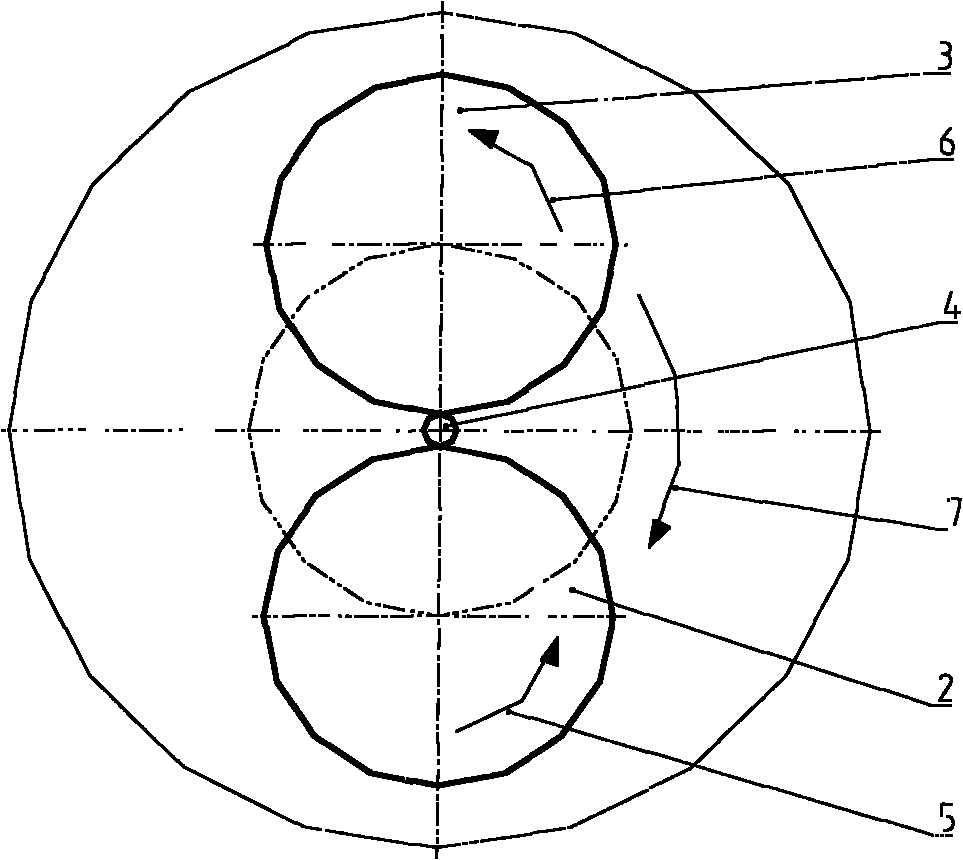

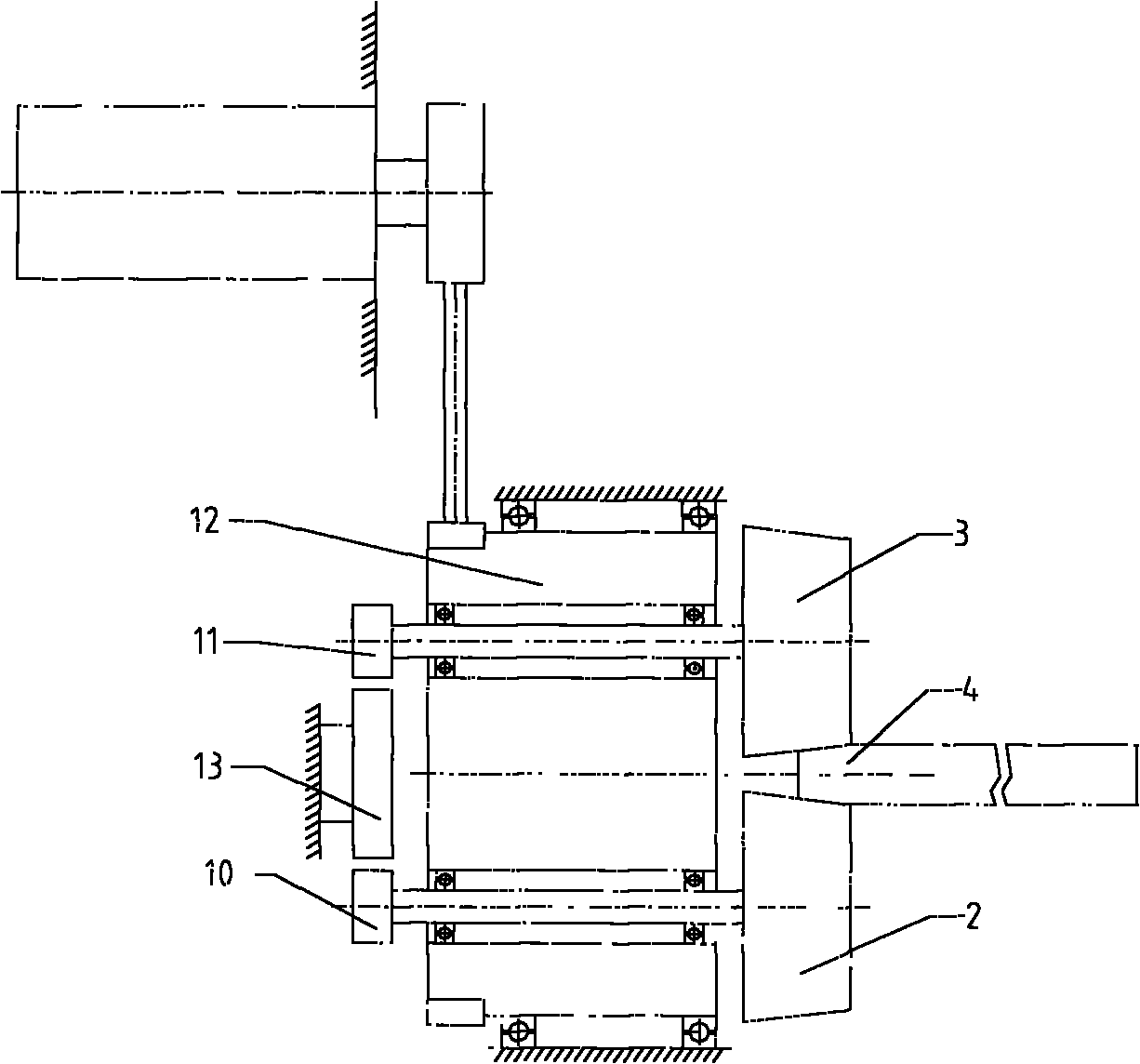

[0014] exist figure 1 Among them, the grinding head device for grinding silicon cores or other crystal materials of the present embodiment includes a mounting plate 14, a shaft seat, a motor 17, a transmission mechanism, a planetary system and a grinding wheel; the transmission system includes a small pulley 16 and a large pulley 8 And belt 15, motor 17 output ends are fixedly connected small pulley 16, and small pulley is connected with large pulley by belt 15, and large pulley is fixedly connected on the axle tube 12; Planetary system comprises pinion A10, pinion B11, large The gear 13 and the shaft cylinder 12, the large gear 13 is fixedly connected with the mounting plate 14, the pinion is arranged on the outside of the large gear and meshes with the large gear respectively; the shaft cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com