Automatic bottle-inserting needle and catheter assembling device for disposable transfusion apparatuses

A technology of automatic assembly device and bottle inserting needle, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee product quality, low work efficiency, and high labor intensity of workers, so as to improve the degree of automation and improve the Production efficiency, the effect of saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

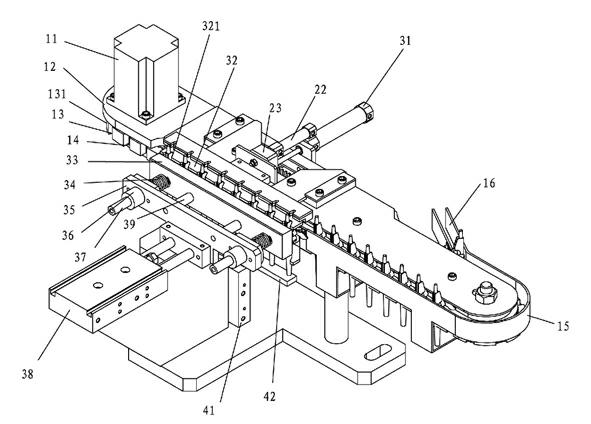

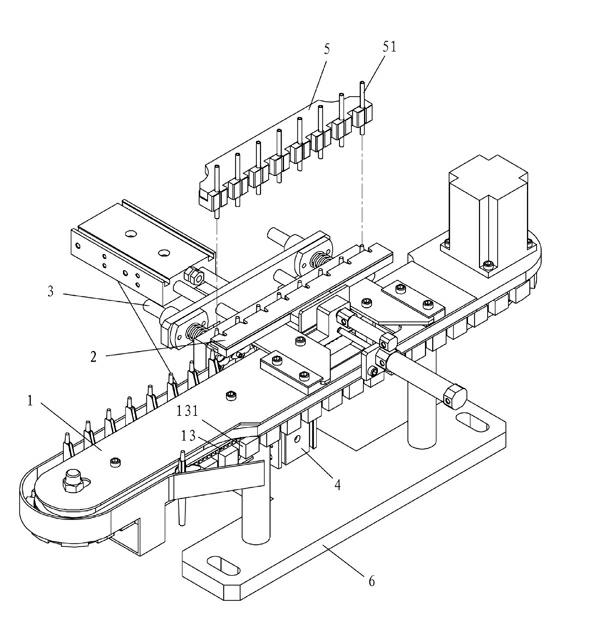

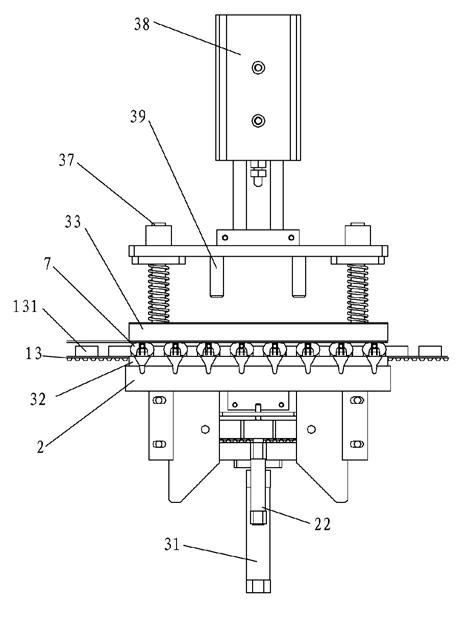

[0027] see figure 1 and figure 2 , an automatic assembly device for inserting needles and catheters of disposable infusion sets, including a step-by-step automatic feeding mechanism 1 for inserting needles, a gluing mechanism 2, an insertion positioning mechanism 3, an insertion mechanism 4, a catheter clamp 5 and a frame 6 .

[0028] The bottle insertion needle stepping automatic feeding mechanism 1 comprises a frame 6, the top surface of the frame 6 is a strip platform 12, the periphery of the strip platform 12 is provided with a feeding slideway 15, and the top surface of the strip platform 12 One side is equipped with stepper motor 11, and the output shaft end of stepper motor 11 stretches to the bottom of frame 6, and the output shaft end of stepper motor 11 is connected with synchronous belt 13 by synchronous belt pulley 14, and synchronous belt 13 lateral surfaces The square 131 that promotes bottle inserting pin is installed evenly.

[0029] The top surface and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com