Hydro-hybrid ceramic main shaft device

A spindle device, dynamic and static pressure technology, applied in the field of mechanical assembly parts, can solve the problems of poor bearing capacity of water-lubricated spindles, short life of metal friction pairs, temperature rise of oil-lubricated spindles, etc., to make up for poor tensile strength and improve spindle life , The effect of increasing the spindle speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

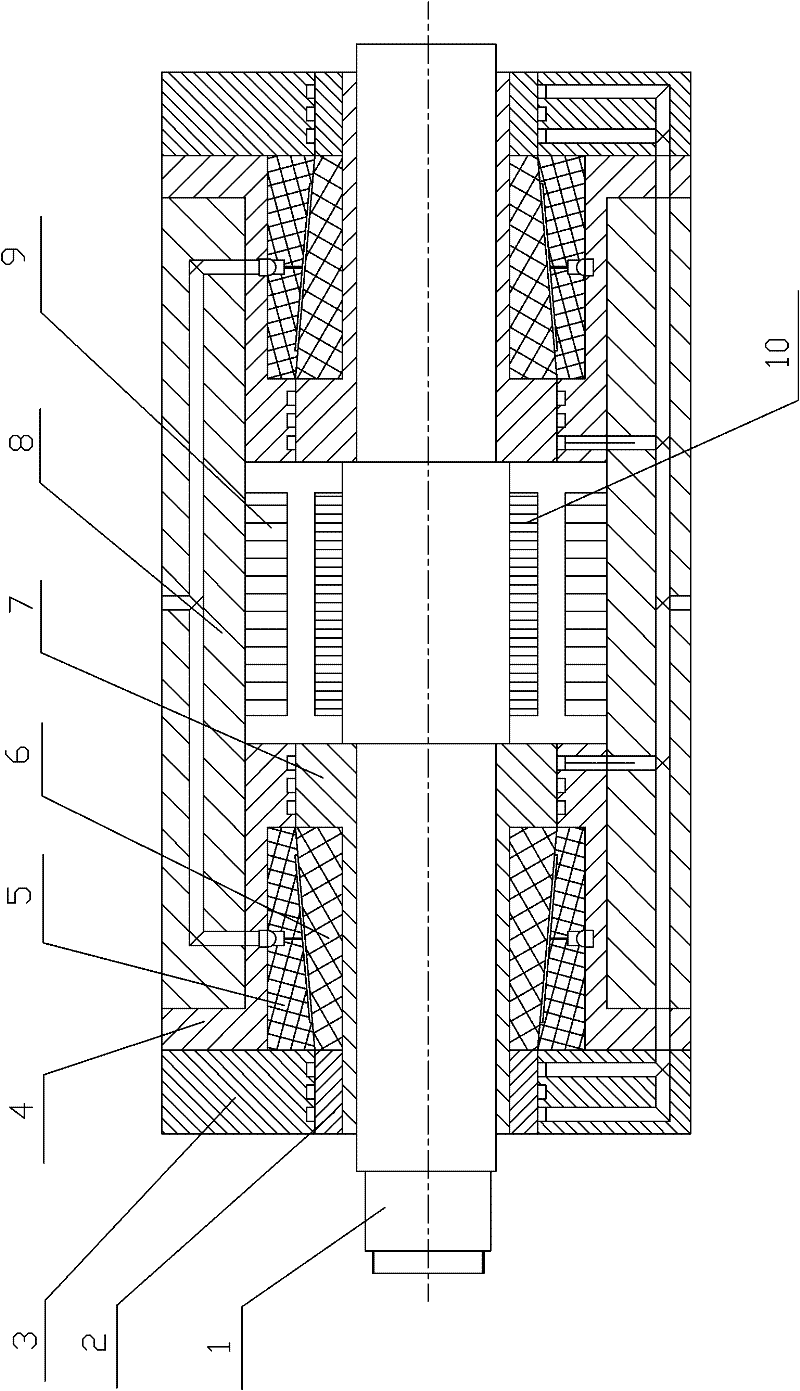

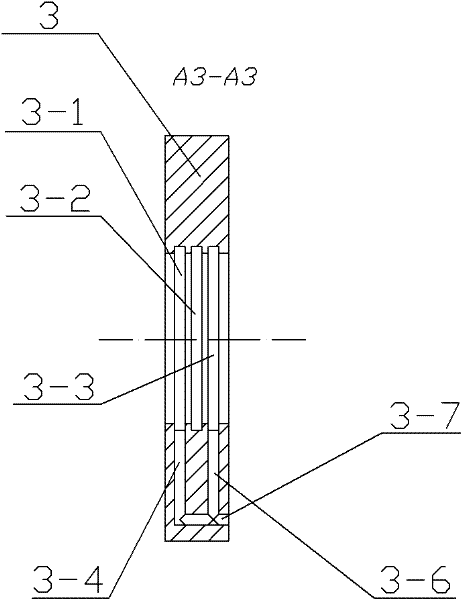

[0046]Aiming at the problems of high temperature rise and low bearing capacity of water-lubricated spindles at high speeds for ordinary oil-lubricated spindles, the present invention proposes a dynamic and static pressure ceramic spindle device, wherein the lubricant of the spindle is water-based lubricating fluid. In order to solve the problems of poor wear resistance and high thermal expansion coefficient of the traditional spindle-bearing metal friction pair, and to adapt to the state where boundary friction and dry friction are prone to occur in the low-viscosity lubrication of water-based lubricating fluid, the material of the spindle-bearing friction pair in the present invention for ceramic materials. In view of the fact that the structure of the simple ceramic sliding bearing is too simple to meet the working needs of the main shaft, and the ceramic parts are prone to stress concentration, the design of the main shaft structure in the present invention adopts the cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com