Natural gas filter element and manufacturing method thereof

A filter and natural gas technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as affecting the sealing effect, short circuit, end-face sealing installation leakage, etc., to ensure filtration accuracy, improve filtration accuracy, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

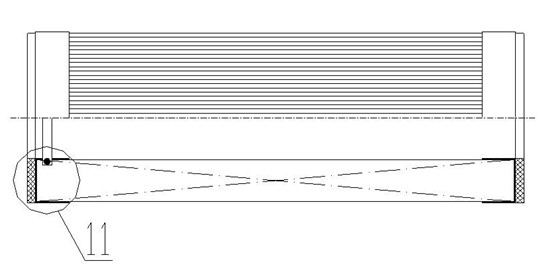

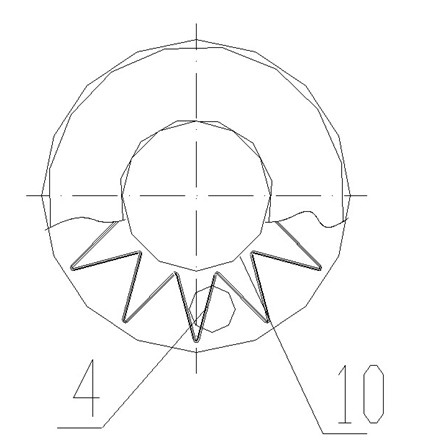

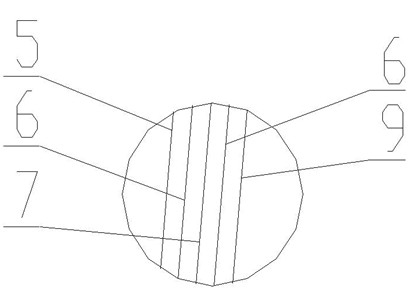

[0032] A natural gas filter element such as Figure 1 to Figure 4 As shown, it includes: a filter layer 4 and a core tube 10 , and the end 11 of the entire filter element includes a fixing ring 3 , a sealing gasket 2 , a sealing ring 1 and epoxy resin paste 12 . The filter layer 4 is a pleated filter layer, which adopts a multi-layer composite structure combining surface filtration and depth filtration, including an outer layer 5 , a middle layer 7 and an inner layer 9 . The outer layer 5 is a dense stainless steel mesh, the middle layer 7 is a polyester or glass fiber filter membrane, the inner layer 9 is a coarse wire mesh, and the non-woven protective layer 6 is used on both sides of the middle layer 7, and the non-woven protective layer 6 has a pore size of 1 to 5 μm.

[0033] The bonding material for pressure injection at the end 11 is epoxy resin mud 12, and then the end of the filter layer 4 is bonded and fixed with the fixing ring 3, and finally the sealing gasket 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com