Circulating water internal cold friction drum for brake device

A brake device and friction drum technology, applied in the direction of brake drums, slack adjusters, etc., can solve the problems of low degree of automation and difficult control of cooling effect, and achieve the effects of saving costs, improving heat decay, and saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

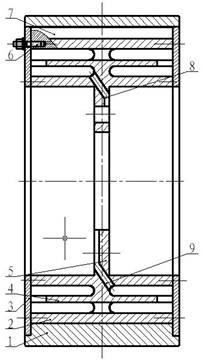

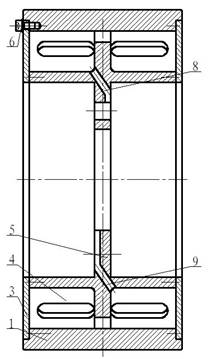

[0024] The outer wheel drum 1 is closely connected with the inner wheel drum through a plurality of keys 7 and related positioning fasteners to form an integral friction drum, forming a circulating water internal cooling friction drum for the braking device; the braking device is internally cooled by circulating water The drum is connected by bolts between the output shaft flange of the automobile gearbox and the flange of the universal joint, that is, it is connected to the transmission shaft of the automobile. During the driving process of the automobile, the inner cooling friction drum rotates with the transmission shaft and can be used as an electromechanical Friction drum for ACBS retarder.

[0025] When this cooling device is used, under a certain pressure, the cooling water enters the friction from the water inlet 8, and flows in the friction under the guidance of the deflector 4, absorbing the friction generated by the friction plate and the friction drum during braking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com