Method for operating an injection system of an internal combustion engine

A technology of injection system and internal combustion engine, applied in the direction of fuel injection control, internal combustion piston engine, combustion engine, etc., can solve the problems of strong deviation of fuel supply, impossibility to accurately achieve fuel injection rate, high sensitivity, and achieve rapid control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] One embodiment of the present invention provides a method for operating a direct injection system of a diesel engine of an automobile, wherein the direct injection system includes one electrically controlled solenoid for each engine cylinder.

[0053] Since the operating method described works equally well for each engine cylinder, this exemplary embodiment is explained below with respect to individual engine cylinders.

[0054] During engine operation, a number of engine cycles occur consecutively within a cylinder, each engine cycle including a fuel injection phase spanning a compression stroke and an expansion stroke.

[0055] The fuel injection phase is carried out by the solenoid injector in a multi-injection mode, which is usually used to perform several different injection processes within the same injection phase.

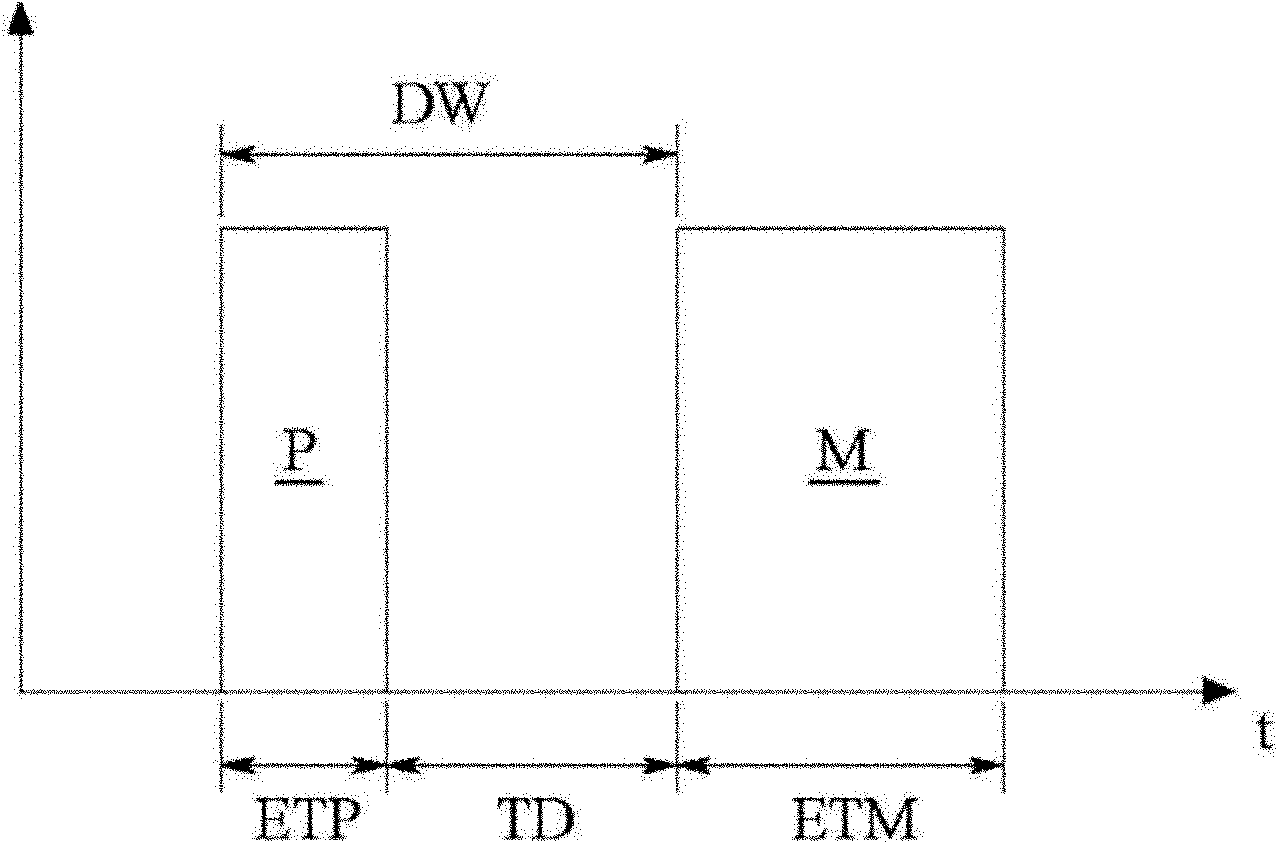

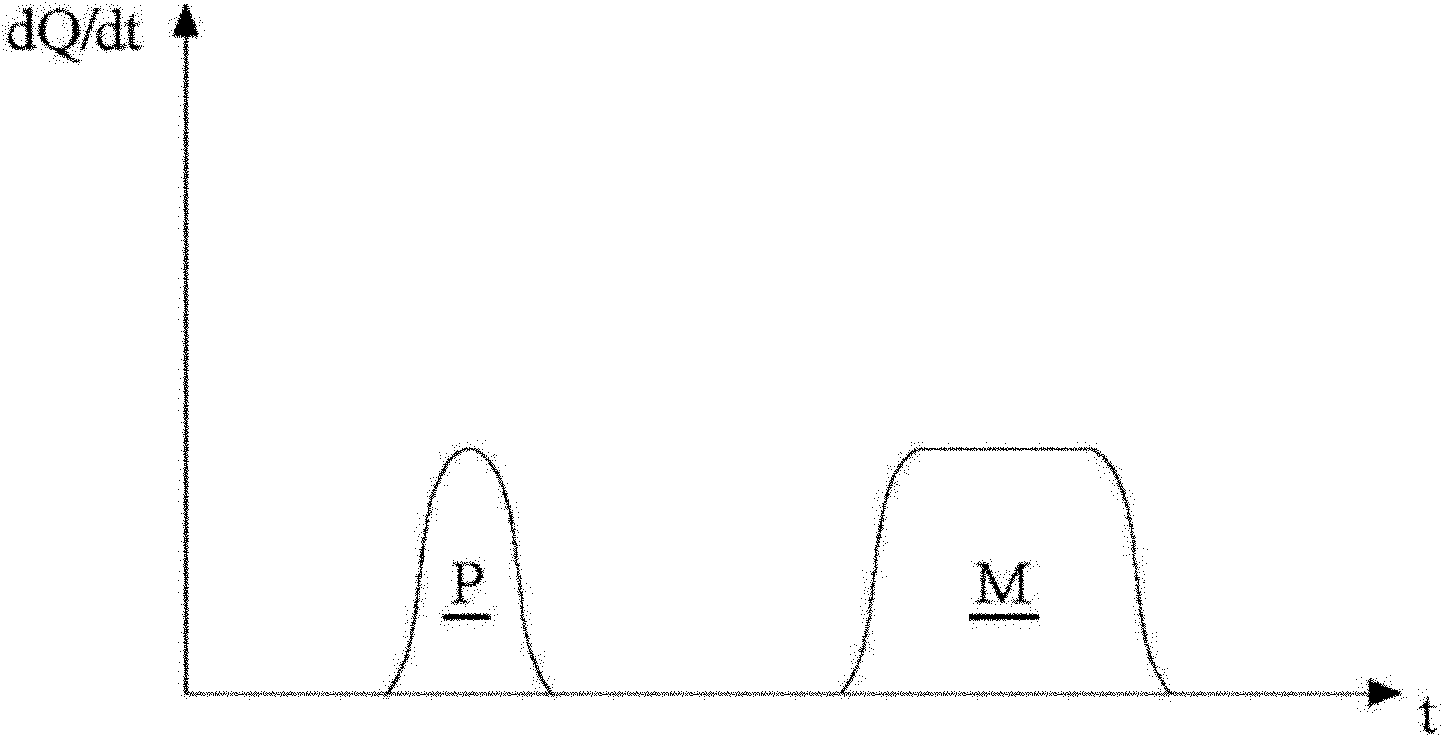

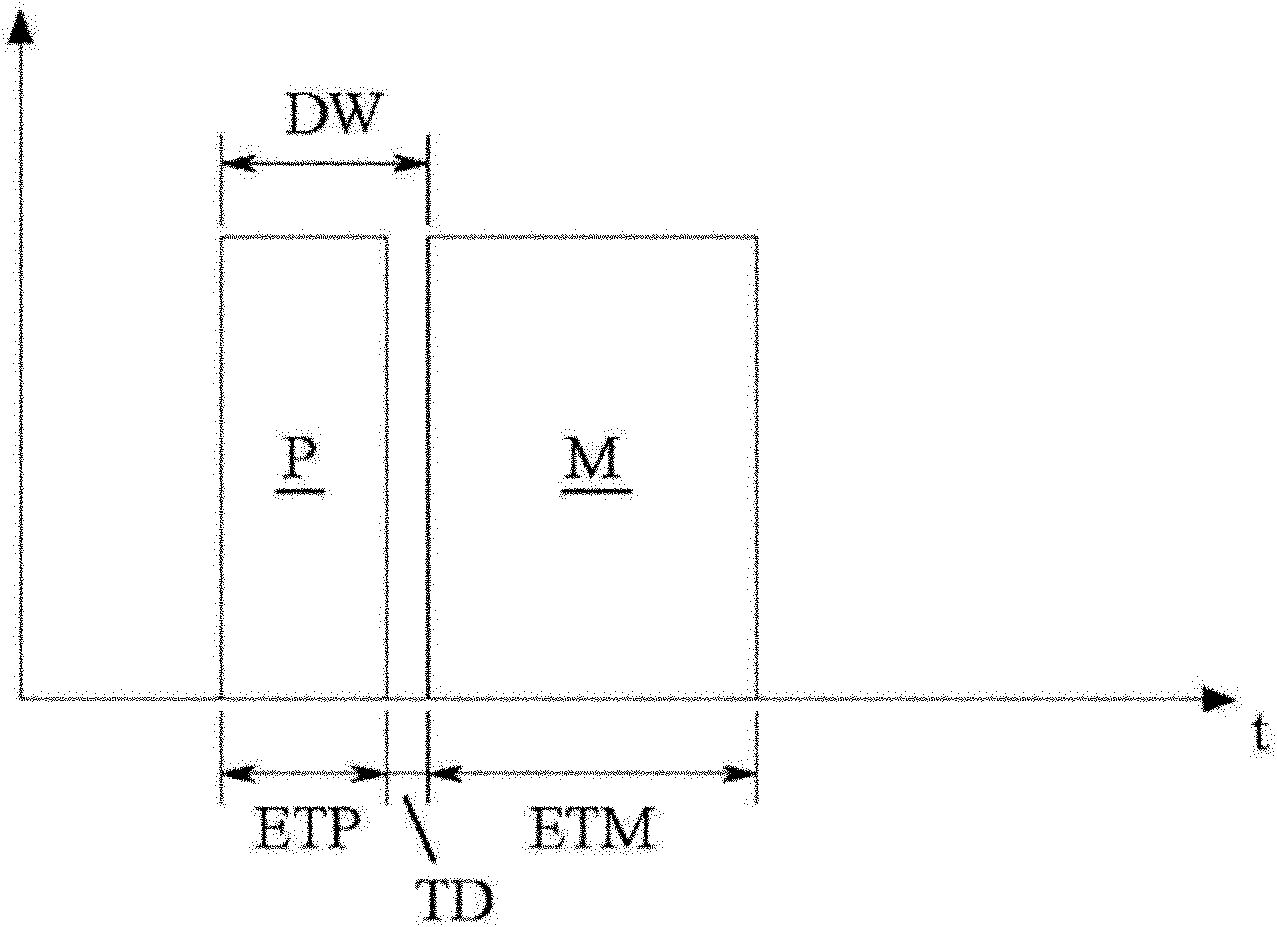

[0056] In this example (see figure 1 with 3 ), the multi-injection mode only includes two consecutive injection processes, namely the pilot inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com