Method of manufacturing heat-preservation and fireproof decorative panel

A decorative board and panel technology, applied in covering/lining, architecture, building structure, etc., can solve the problems of insulation layer limit, insulation layer easy to rise, poor fire protection effect, etc., to increase strength, not easy to deform, strengthen The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for making a thermal insulation and fireproof decorative board, the method comprises the following steps:

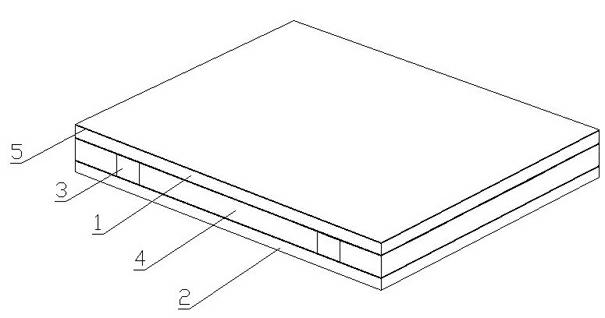

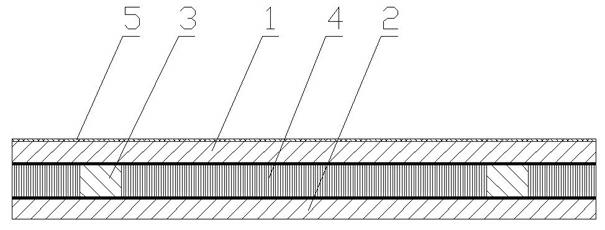

[0026] A. Make the upper panel 1, the lower panel 2, the rock wool layer 4 (the rock wool layer 4 is formed by superimposing and pressing multiple thin fiber layers) and the reinforcing rib 3 respectively.

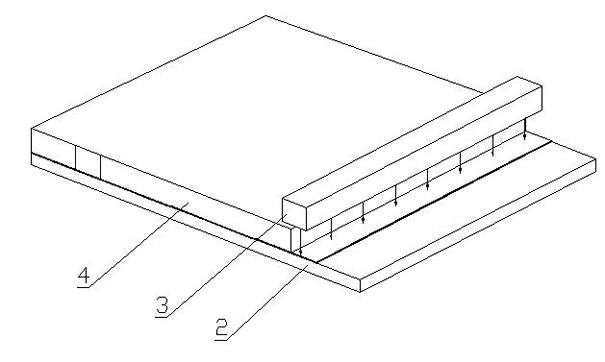

[0027] B. Lay the lower panel 2 flat, and then alternately arrange the rock wool layers 4 and reinforcement ribs 3 and bond them on the lower panel 2 (such as figure 1 shown), and the fibers in the ribs 3 and the rock wool layer 4 are perpendicular to the lower panel 2, and the distance between two adjacent ribs 3 is 5-80 cm. Adhesives can be two-component polyurethane adhesives, two-component epoxy resin adhesives, and the like.

[0028] C. Bond the upper panel 1 to the rock wool layer 4 and the reinforcing rib 3, and the upper panel 1 is parallel to the lower panel 2, and use the bonded test piece as the test piece to be pressed.

[0029] D. Put t...

Embodiment 2

[0034] Another method for making thermal insulation and fireproof decorative panels, the specific steps include the following:

[0035] A. Make the upper panel 1, the lower panel 2, the rock wool layer 4 (the rock wool layer 4 is formed by superimposing and pressing multiple thin fiber layers) and the reinforcing rib 3 respectively.

[0036] B. Lay the lower panel 2 flat, then alternately arrange the reinforcing ribs 3 and the rock wool layer 4 and bond them on the lower panel 2, and the fibers in the reinforcing ribs 3 and the rock wool layer 4 are perpendicular to the lower panel 2 and adjacent to each other. The distance between the two reinforcing ribs 3 is 5-80cm;

[0037] C. Put the bonded lower panel 2, rock wool layer 4 and reinforcing rib 3 on the press, and the press compacts the rock wool layer 4, reinforcing rib 3 and lower panel 2 as a semi-finished product,

[0038] D. Bond the upper panel 1 to the semi-finished rock wool layer 4 and the reinforcing rib 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com