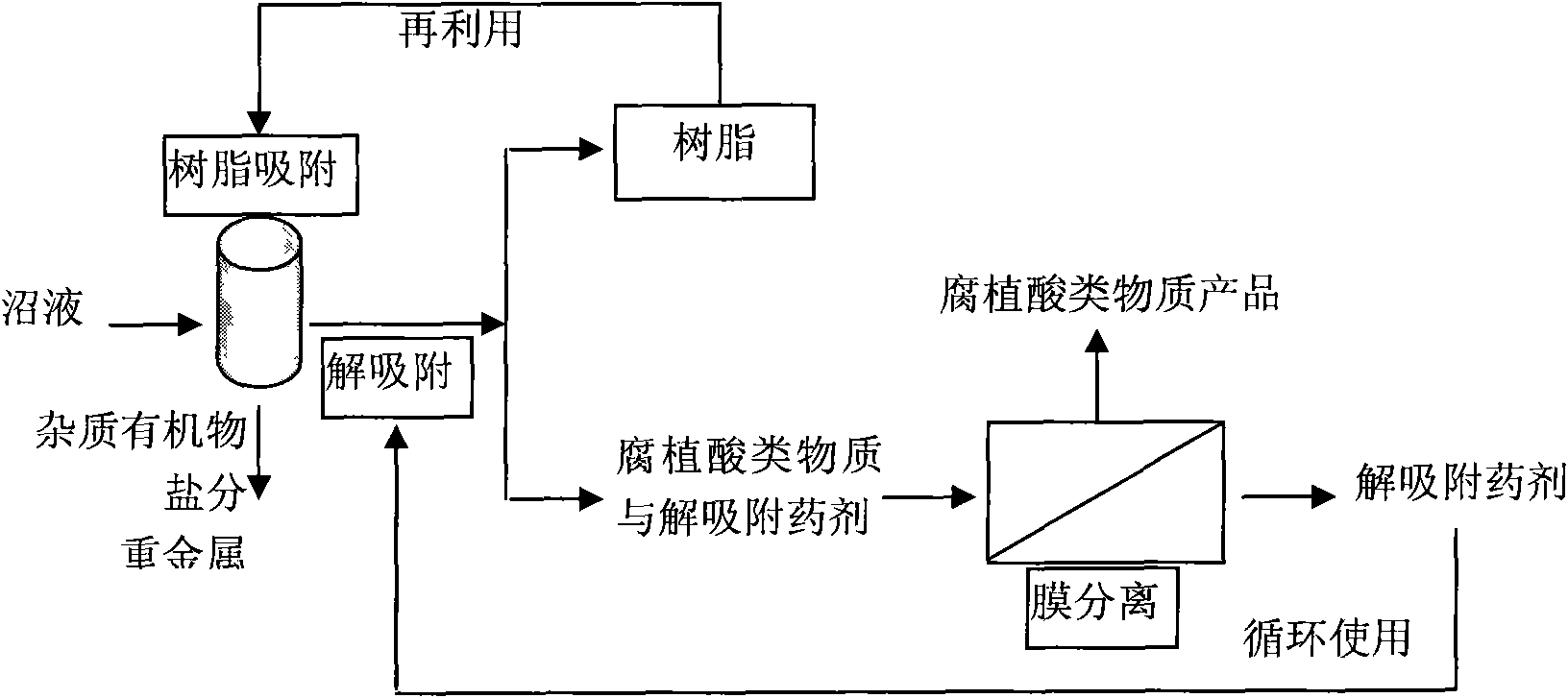

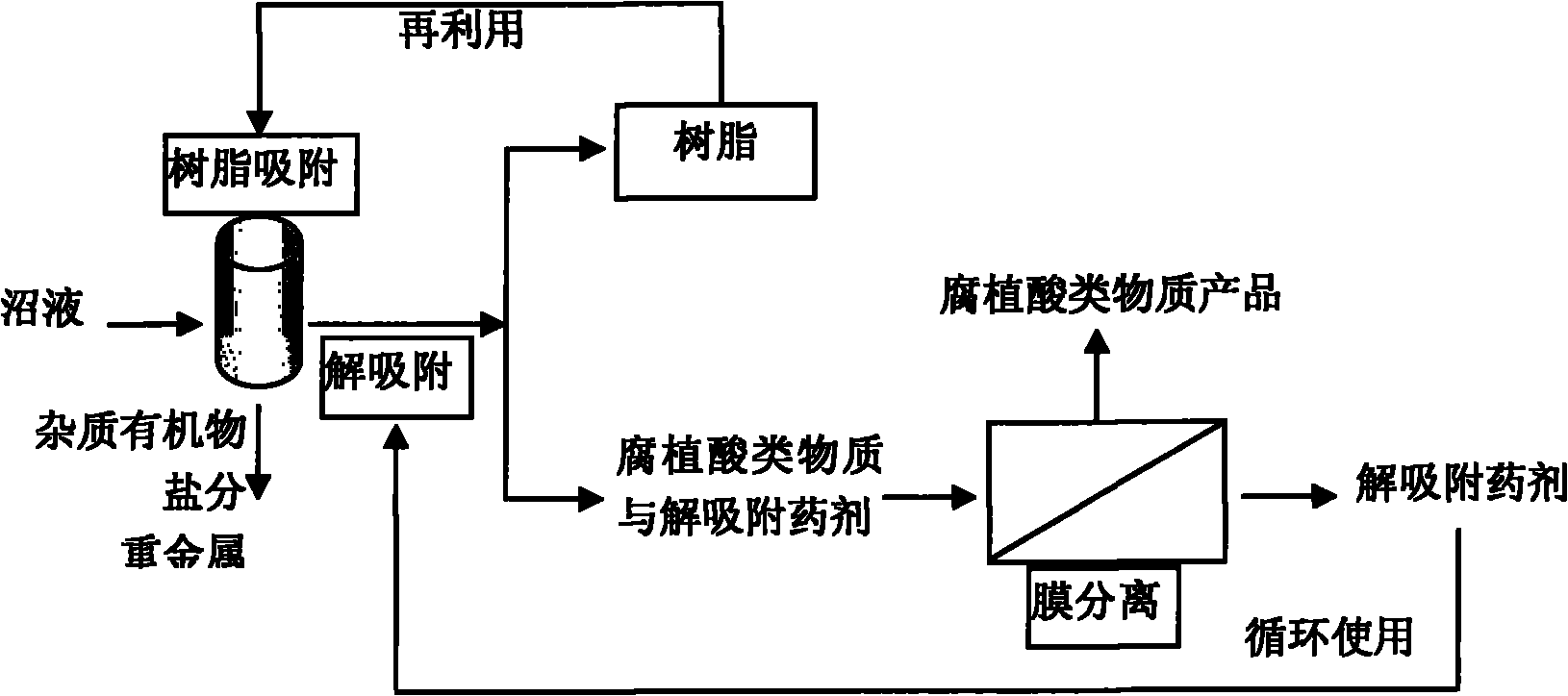

Method for extracting humic acid substances from methane fluid

A humic and acid technology, used in organic chemistry and other directions, can solve the problems of low recovery rate and low purity, and achieve the effect of improving purity, improving purity and concentration, and improving the level of resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Landfill leachate is a typical biogas slurry. Taking a domestic waste landfill as an example, the amount of leachate produced is 100m 3 / d, after being treated by a membrane bioreactor (MBR), the effluent COD concentration is 1700mg / L, and the concentration of humic acid substances is 1000mg / L (HS content is 59%). In this embodiment, humic acid substances are separated and extracted from the above-mentioned treated water.

[0031] The 717 resin was selected, and the three-stage series method was used for adsorption. The total amount of resin required is 6t, the cross section of the resin column is Φ1.6m, and the height is 1.6m. Filter the biogas slurry through sand filtration to remove suspended matter, and the pretreated biogas slurry enters the 717 resin column. The apparent hydraulic retention time of the leachate is 2 hours, and then the desorption liquid prepared by the desorption agent (the desorption solution used here is The medicament consists of NaCl, NaOH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com