Method for inhibiting bud through bud in organic flue-cured tobacco production

A flue-cured tobacco and organic technology, which is applied in the field of bud suppression in organic tobacco leaf planting, can solve labor-intensive and time-consuming problems, and achieve the effects of reducing production costs, being easy to master, and simple and reasonable in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The test site of the present invention is the organic tobacco leaf production base of the Raw Material Department of China Tobacco Yunnan Industrial Co., Ltd., which is located in Lawu Township, Binchuan County, Dali Prefecture, Yunnan Province.

[0018] Test materials: the variety of flue-cured tobacco is NC297, at the budding stage; the tools used are branch shears (commercially available products).

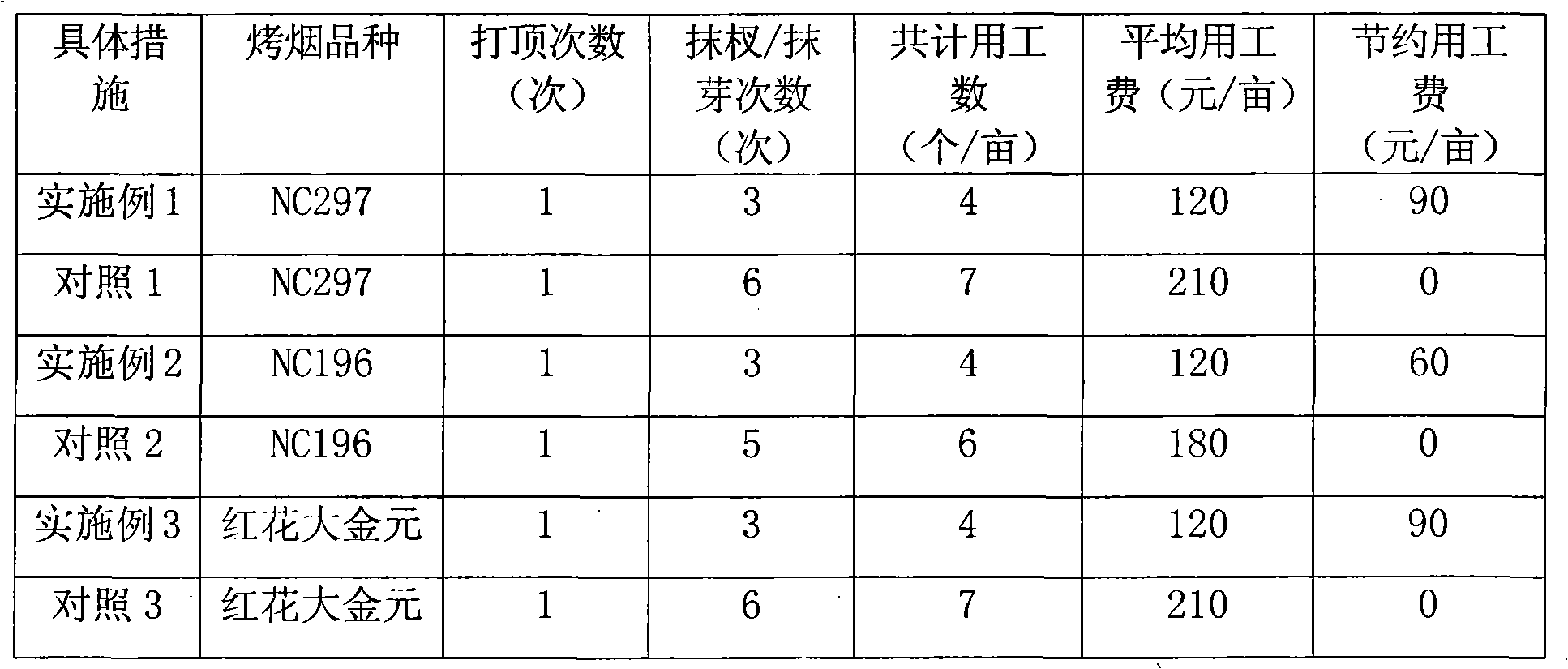

[0019] Specific measures: topping is carried out from the budding of the tobacco plants in the tobacco field to the opening of the central flowers of the tobacco plants. Generally, topping is carried out in the evening on a sunny day. Calculated within 22 leaves of each tobacco plant), and at the same time, the number of leaves left by each tobacco plant is 22 pieces. After topping, when the axillary buds germinate and grow to 10 centimeters in succession, wipe the branches, and leave 5 centimeters of branches at the base of the tobacco branches. Wipe the branches once e...

Embodiment 2

[0021] Test location: Organic Tobacco Leaf Production Base of Raw Material Department of China Tobacco Yunnan Industrial Company, located in Lawu Township, Binchuan County, Dali Prefecture, Yunnan Province.

[0022] Test materials and methods: The variety of flue-cured tobacco is NC196: the center flower is open, and the topping and wiping are done manually.

[0023] Specific measures: In addition to leaving 21 tobacco leaves per plant during topping, and leaving 2 leaflets under the inflorescence at the same time, after topping, when the axillary buds germinate and grow to 5 cm in succession, wipe the branches and keep 3 cm branches at the base of the tobacco branches , and the rest of the measures are the same as in Embodiment 1, and will not be repeated here. The control is the traditional manual topping and bud stroking, a comparative experiment in the same field. After the topping, the axillary buds grow and the bud stroking starts, and the bud stroking is once every 7 da...

Embodiment 3

[0025] Test location: Organic Tobacco Leaf Production Base of Raw Material Department of China Tobacco Yunnan Industrial Company, located in Lawu Township, Binchuan County, Dali Prefecture, Yunnan Province.

[0026] Test materials and methods: The variety of flue-cured tobacco is Honghua Dajinyuan: the center flower is open, and the topping and branching are directly done manually.

[0027] Specific measures: In addition to leaving 18 tobacco leaves per plant during topping, and leaving 2 leaflets under the inflorescence at the same time, after topping, when the axillary buds germinate and grow to 8 cm in succession, wipe the branches and leave 4 cm fork stems at the same time, the other measures are the same as Embodiment 1 is the same and will not be repeated here. The control is the traditional manual topping and bud stroking, and the comparison experiment in the same field. After the topping, the axillary buds grow and start the bud stroking. The bud stroking is once every...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com