Microstrip antenna element with controllable directional diagram

A technology of microstrip antenna and pattern, applied in the direction of antenna, antenna grounding device, electrical components, etc., can solve the problems of changing the maximum point of the antenna array, low antenna efficiency, and high external dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

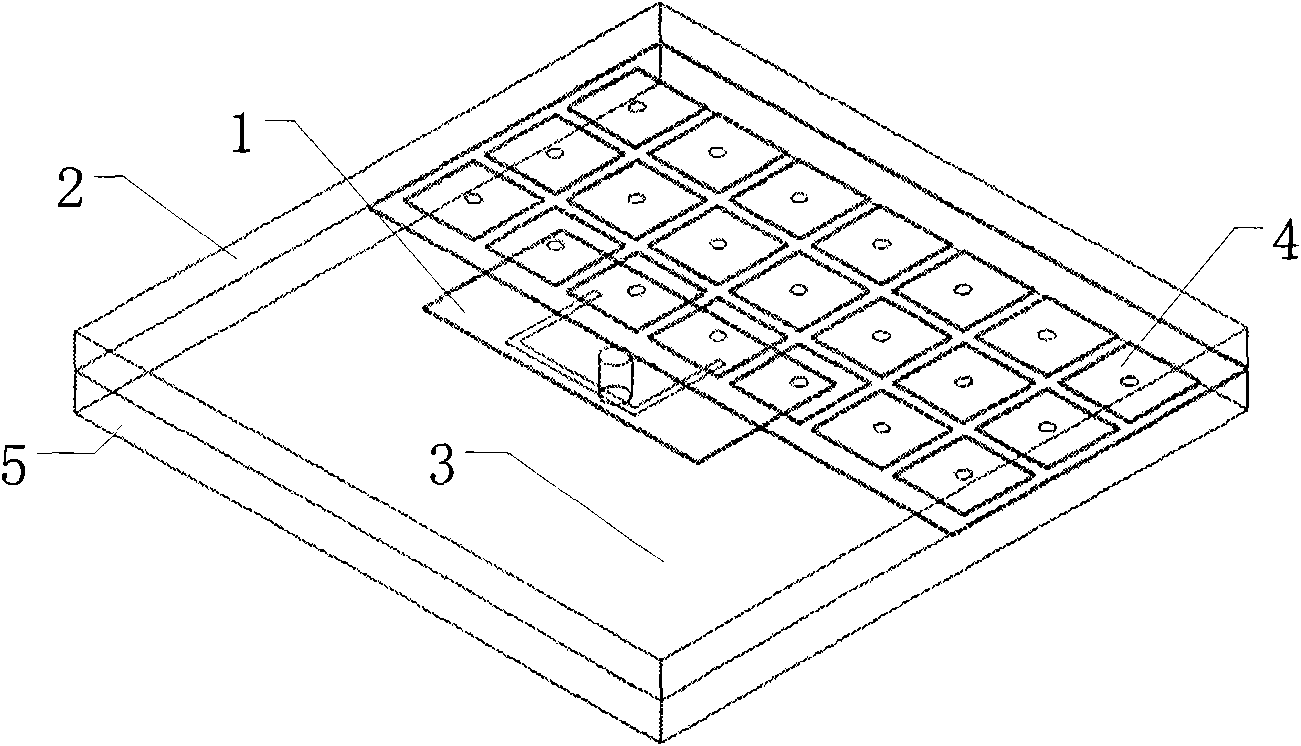

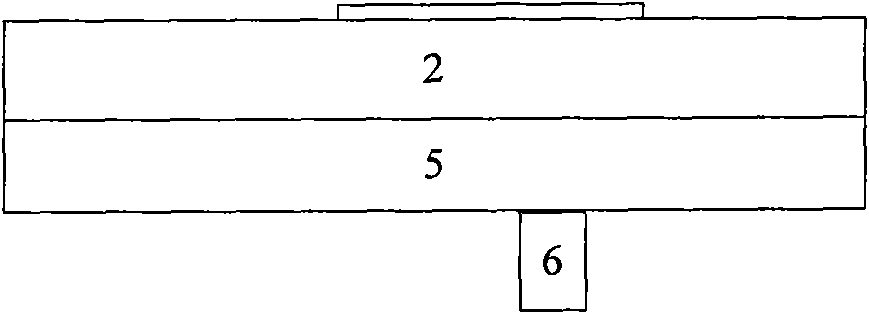

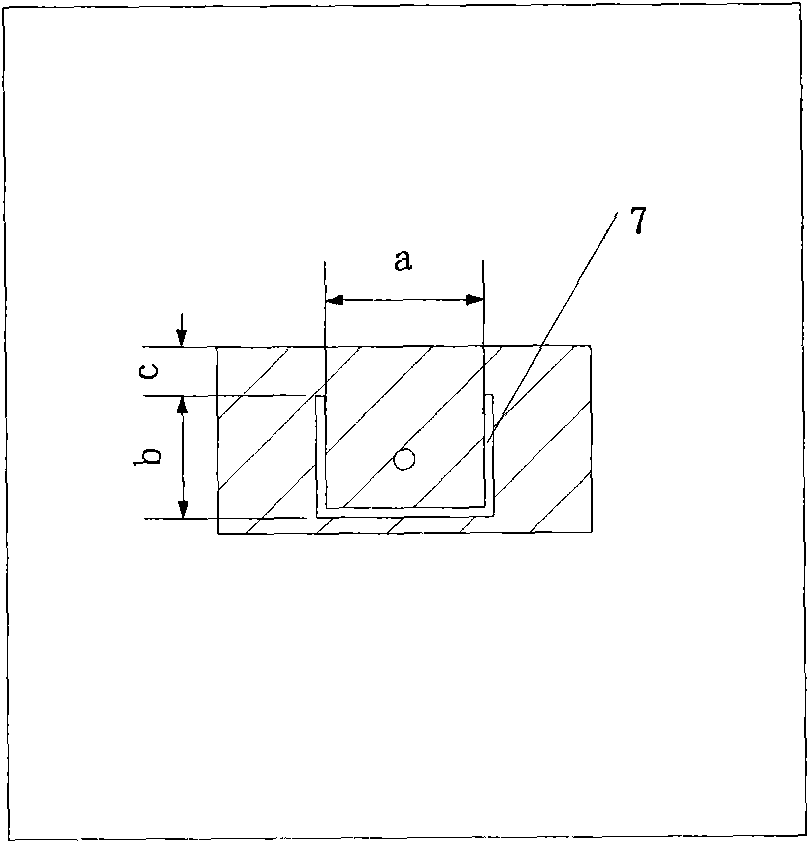

Embodiment 1

[0022] to combine figure 2 Or 6, a microstrip antenna unit with a controllable pattern, using double-layered dielectric boards, the area of the two dielectric boards is 50mm×50mm, the surface of the first layer of dielectric board 2 is etched with the microstrip antenna unit 1, and its The size is 21.6mm×11.4mm; the microstrip antenna unit 1 has a U-shaped slit 7 etched on the first layer of dielectric substrate 2, the dielectric constant of the first layer of dielectric substrate 2 is 2.7, the thickness is 3.5mm, and the U-shaped slit The width of the U-shaped slots is 0.6mm, the distance between the U-shaped slots parallel to each other is 10mm, and their length is 15.5mm. Feed. The upper surface of the second dielectric board 5 is composed of a metal ground 3 and an EBG metal patch 4, the lower surface of the second dielectric board 5 is a complete metal ground 9, and the EBG metal patch 4 passes through the second metal via hole 8. The layer dielectric board 5 is conn...

Embodiment 2

[0024] to combine figure 2Or 7, further improvement on the basis of the embodiment can obtain a microstrip antenna unit with a controllable pattern, using double-layered dielectric boards, the area of the two-layer dielectric boards is 50mm×50mm, and the first layer of dielectric boards 2 Surface etching microstrip antenna unit 1, the size of which is 21.6mm×11.4mm; microstrip antenna unit 1 has a U-shaped slit 7 etched on the first layer of dielectric substrate 2, and the dielectric constant of the first layer of dielectric substrate 2 is 2.7, the thickness is 3.5mm, the width of the U-shaped slot is 0.6mm, the distance between the U-shaped slots parallel to each other is 10mm, and their length is 15.5mm, the distance between the upper edge of the U-shaped slot and the upper edge of the microstrip antenna unit 1 is 3.1mm, and fed through the coaxial probe 6. The upper surface of the second dielectric board 5 is composed of a metal ground 3 and an EBG metal patch 4, the lo...

Embodiment 3

[0026] combine figure 2 Or 8, improving Embodiment 2 to obtain a microstrip antenna unit with a controllable pattern, using double-layer dielectric boards, the area of the two-layer dielectric boards is 50mm×50mm, and the surface of the first layer of dielectric board 2 Etching the microstrip antenna unit 1, the size of which is 21.6mm×11.4mm; the microstrip antenna unit 1 has a U-shaped slit 7 etched on the first layer of dielectric substrate 2, the dielectric constant of the first layer of dielectric substrate 2 is 2.7, The thickness is 3.5mm, the width of the U-shaped slot is 0.6mm, the distance between the U-shaped slots parallel to each other is 10mm, and their length is 15.5mm, and the distance between the upper edge of the U-shaped slot and the upper edge of the microstrip antenna unit 1 is 3.1mm , and fed through the coaxial probe 6. The upper surface of the second dielectric board 5 is composed of a metal ground 3 and an EBG metal patch 4, the lower surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com