Manufacturing method of hydraulic model

A production method and technology of hydraulic models, applied in the direction of hydraulic models, etc., can solve problems such as difficult model bed setting, work delays, increased workload, etc., and achieve no special technical requirements, small scope of application, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

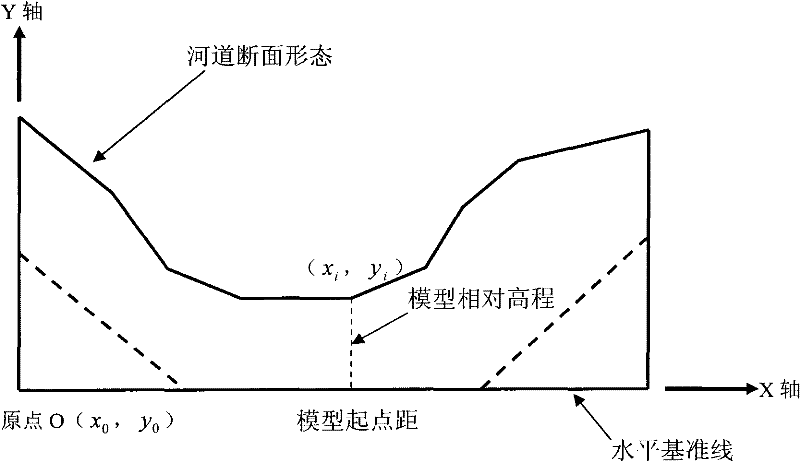

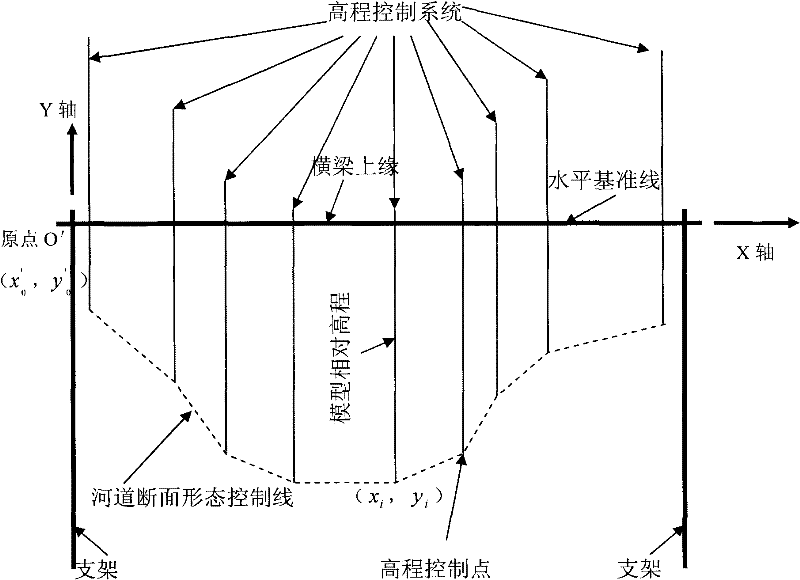

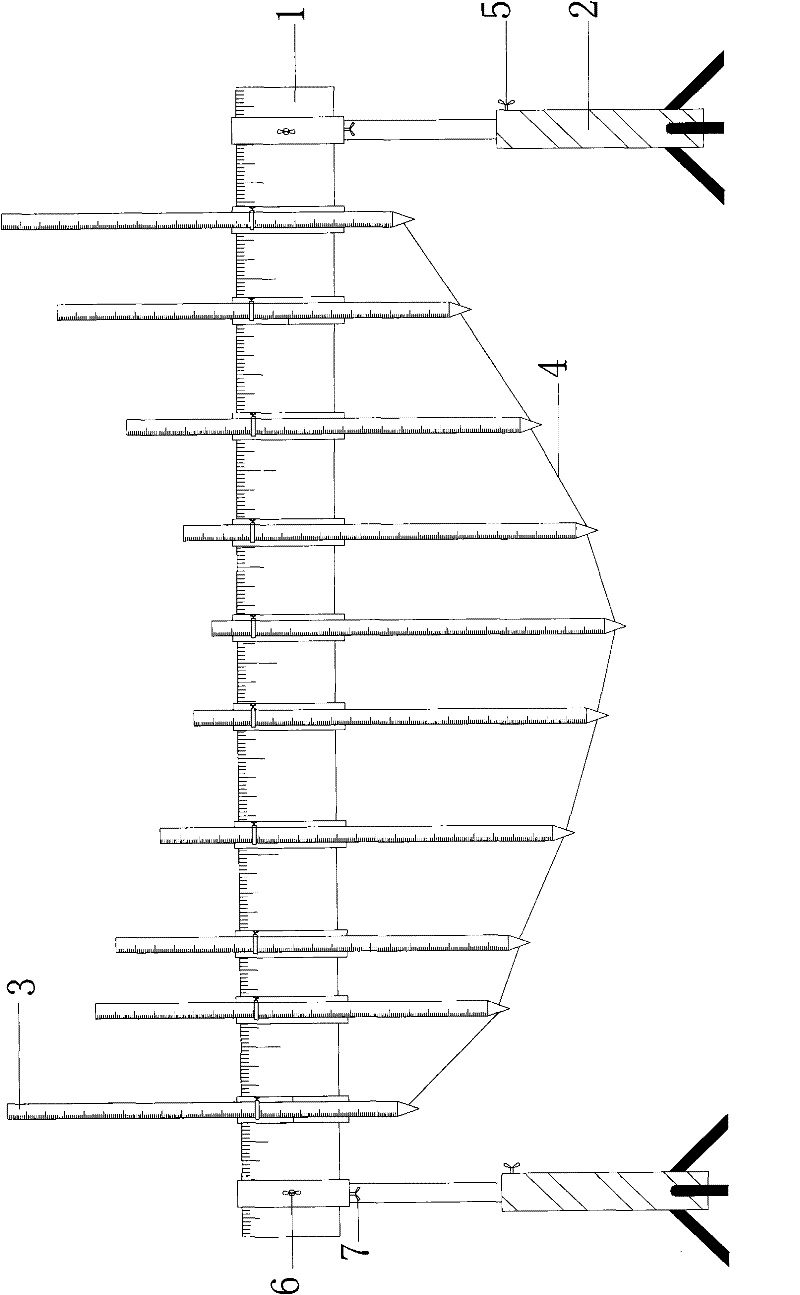

[0018] Usually, the shape of the section template for making the channel section model is as follows: figure 1 As shown, the material of the section formwork is generally plywood. Limited by the strength and specifications of plywood (1.44m×2.4m), the maximum model vertical height difference of a section formwork is not easy to exceed 1m, the average vertical height difference of the model is not easy to exceed 0.5m, and the horizontal distance of the model is not more than 2.4m. Usually a complete A section is composed of several section templates. At the same time, in order to facilitate the embedment of the section template during terrain production, the left and right lower corners of the section template can be sawed off along the thick dotted line in the figure during terrain production, without affecting the accuracy of terrain production. Under normal circumstances, after the topography of the model fixed bed is completed, the section formwork needs to be taken out to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com