Ultrahigh-speed shuttleless narrow loom

An ultra-high-speed, narrow-width technology, applied in the field of weaving, can solve the problems of large assembly maintenance, poor weaving precision, and low weaving speed, and achieve the effects of convenient use and maintenance, good stability, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

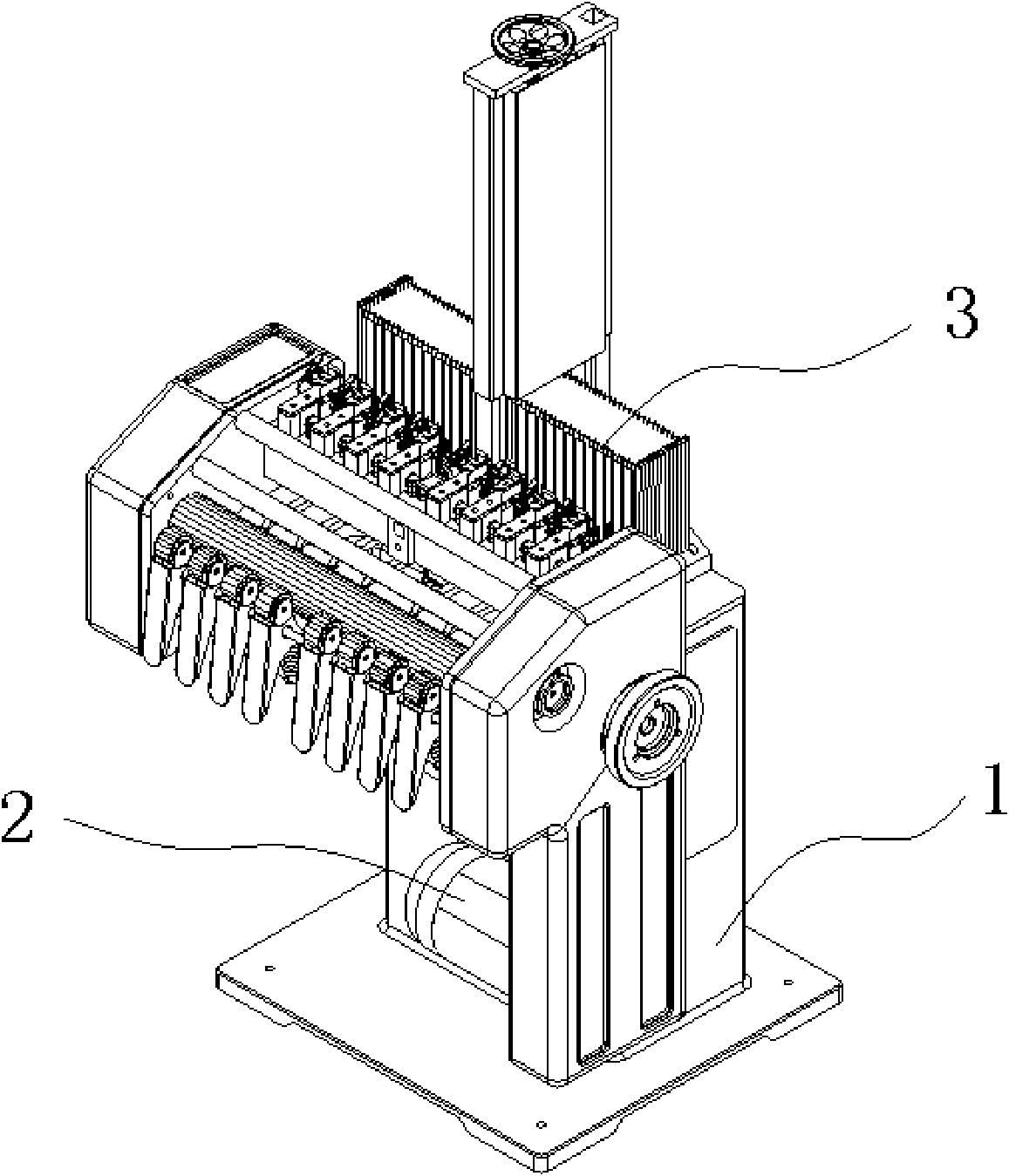

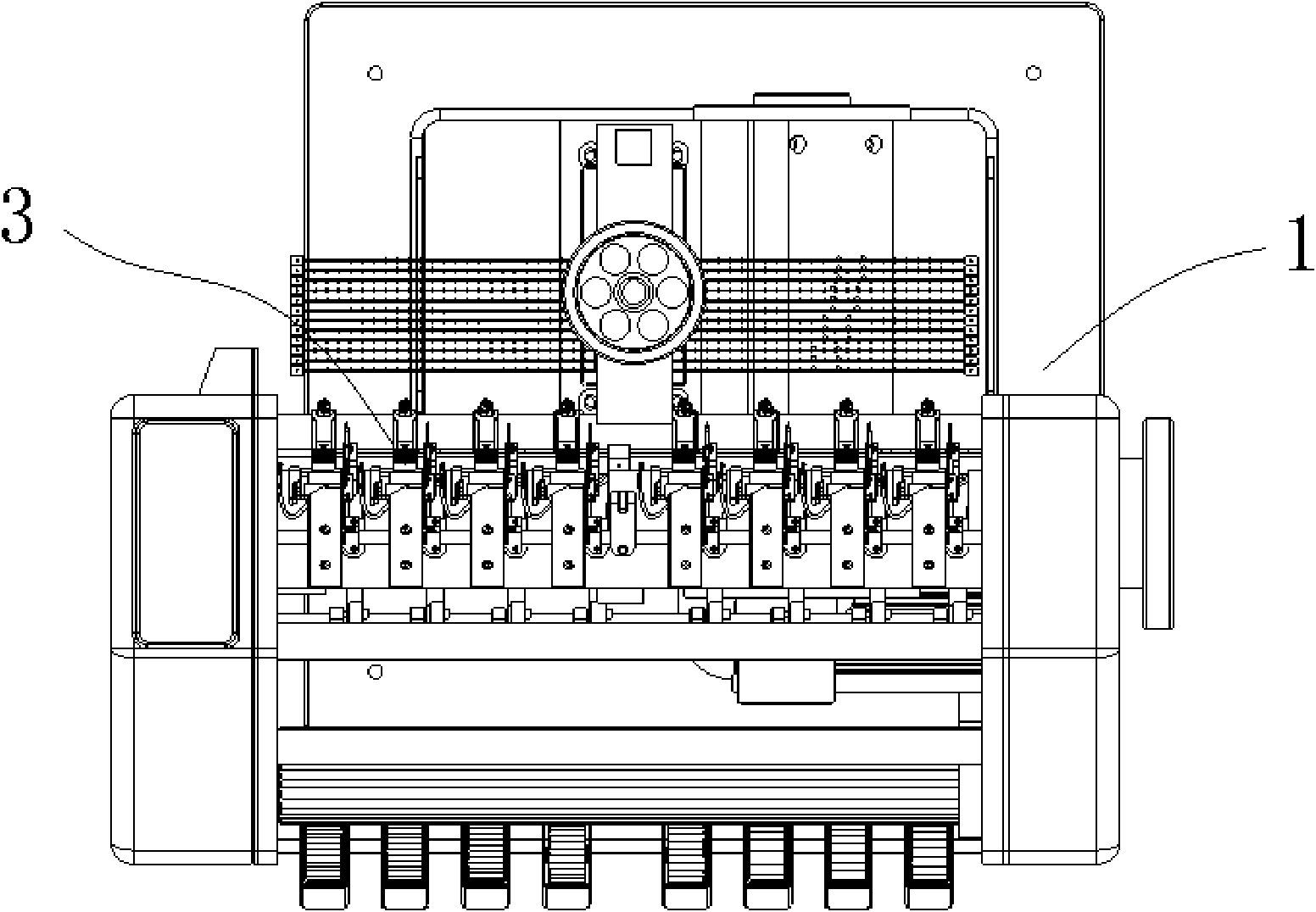

[0030] see figure 1 , figure 2 , a kind of ultra-high-speed shuttleless narrow-width loom in this embodiment is provided with a frame 1, and a drive device 3 installed in the frame works by a weaving mechanism 3 driven by the drive device through transmission systems such as worm gears, chain sprockets, etc. .

[0031] The weaving mechanism 3 comprises a weft insertion mechanism 31, a heald frame mechanism 32, a flower plate chain 33, and a rocker arm 34. A reeding device is arranged between the weft insertion mechanism 31 and the heald frame mechanism 32, and a hemming device, a winding device, glue delivery mechanism.

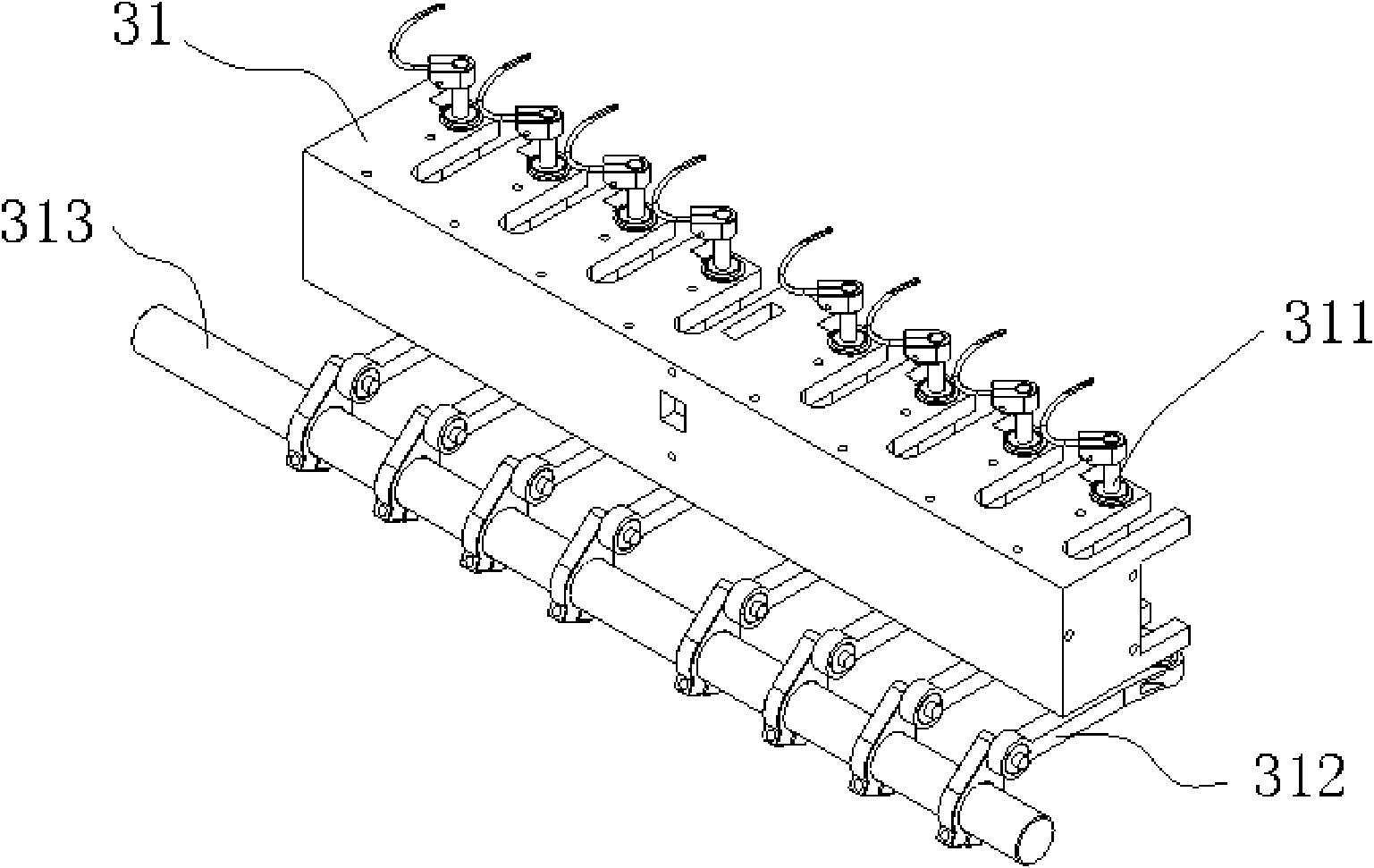

[0032] Such as image 3 As shown, the weft insertion mechanism 31 is a structure of the integral base segment clamping type, and the tensioning seam is made by wire cutting at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com