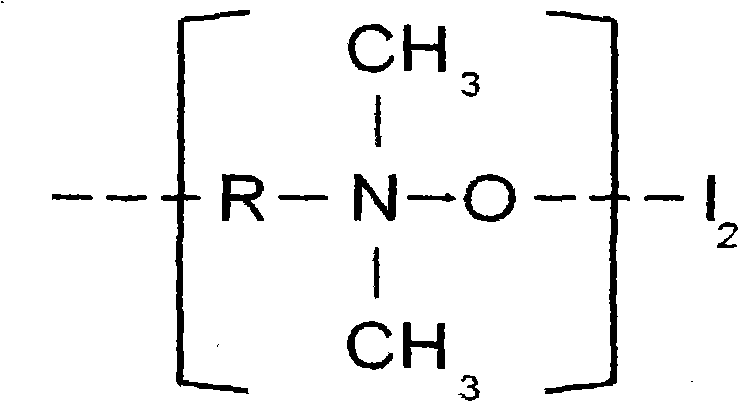

Cocoyl dimethyl ammonium iodine oxide complex

A coco-based dimethyl ammonium oxide and iodine complex technology, which is applied in organic chemistry, biocides, animal repellents, etc., can solve the problem of affecting the elimination of Bacillus subtilis by iodine complexes of non-ionic surfactants Ability, non-ionic surfactant iodine complex bactericidal ability decline and other problems, to achieve the effect of easy-to-obtain raw materials, simple synthesis process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put the raw materials in the following proportions by weight:

[0019] Coco Dimethyl Ammonium Oxide 90 parts

[0020] 6 parts of iodine (I),

[0021] 4 parts citric acid.

[0022] According to the synthesis process route, the cocoyl dimethyl ammonium oxide iodine complex whose appearance is dark purple thick liquid can be produced; the iodine content can be determined above 5% by sodium thiosulfate chemical titration method, and the pH value can be determined At 4-5.

Embodiment 2

[0024] Put the raw materials in the following proportions by weight:

[0025] Coco Dimethyl Ammonium Oxide 86 parts

[0026] Iodine (I) 10 parts,

[0027] 4 parts citric acid.

[0028] According to the synthesis process route, the cocoyl dimethyl ammonium oxide iodine complex whose appearance is dark purple thick liquid can be produced; the iodine content can be determined above 8% by sodium thiosulfate chemical titration method, and the pH value can be determined At 4-5.

Embodiment 3

[0030] Put the raw materials in the following proportions by weight:

[0031] Coco Dimethyl Ammonium Oxide 82 parts

[0032] 12 parts of iodine (I),

[0033] 6 parts of citric acid.

[0034] According to the synthesis process route, the cocoyl dimethyl ammonium oxide iodine complex with the appearance of dark purple thick liquid can be produced; the iodine content can be determined above 10% by sodium thiosulfate chemical titration method, and the pH value can be determined At 4-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com