Tungsten alloy target material and preparation method thereof

A technology of tungsten alloy and target material, which is applied in the field of high-density tungsten alloy target material and its preparation, can solve the problems of unfavorable discharge intermittent sintering of particle pores, unfavorable sintering of large-size products, uneven temperature distribution, etc., to increase density and sintering time, reducing sintering time, and inhibiting the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

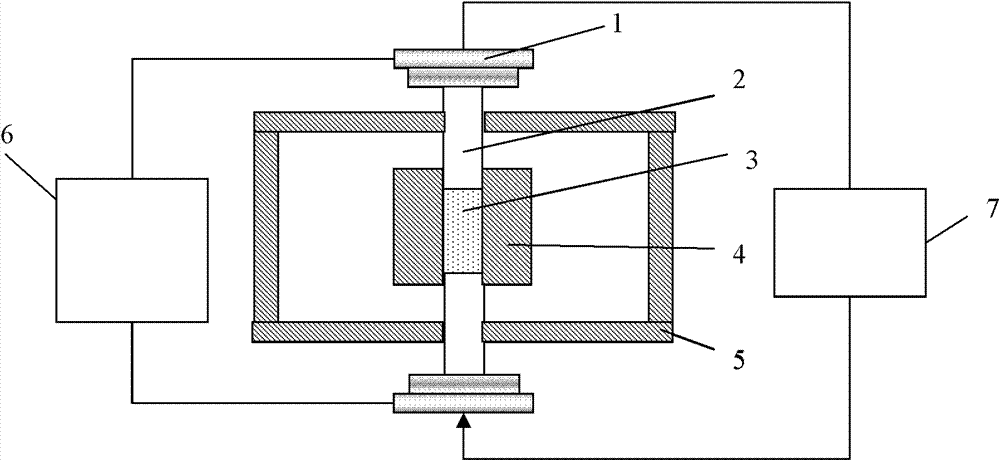

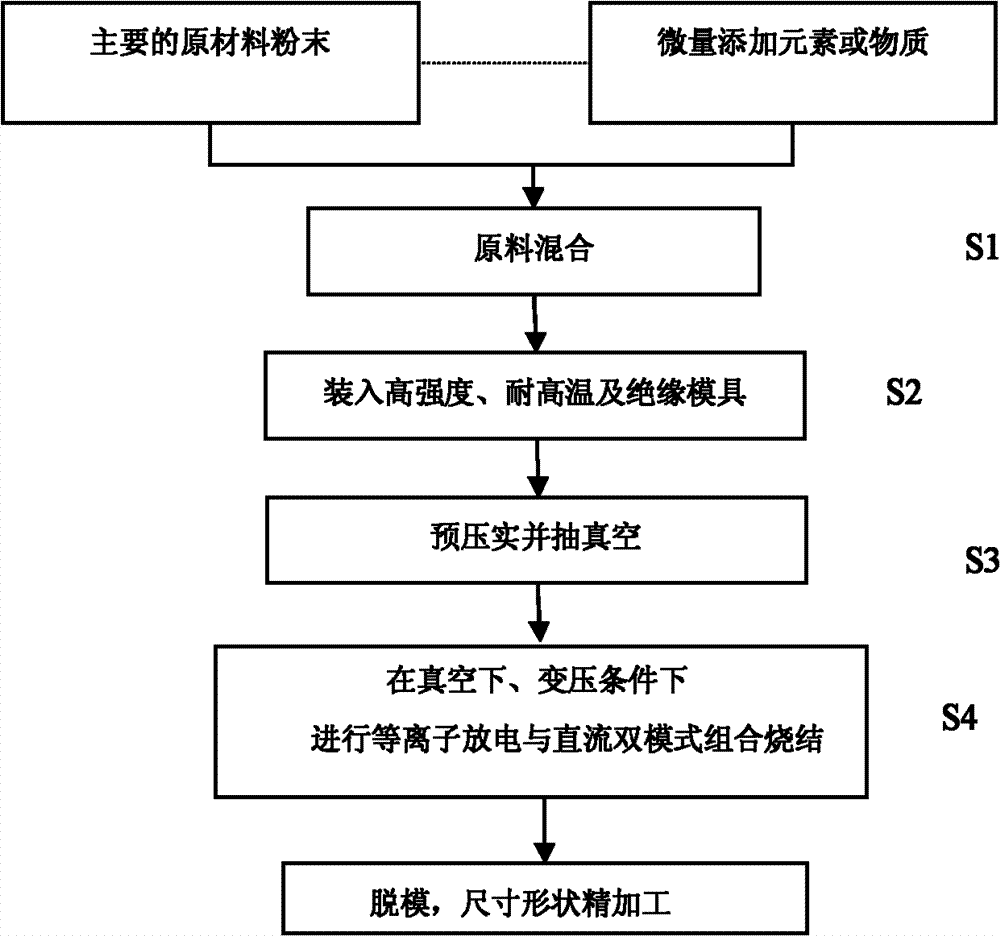

[0043] Sintering mode: variable voltage, fixed pulse current and fixed direct current dual-mode sintering, using devices such as figure 1 As shown, the operation steps are as follows figure 2 shown.

[0044] W powder with an average particle size of 0.5-30 μm (purity 99.99%), Ti powder with an average particle size of 20-30 μm (purity 99.99%) and yttrium powder with an average particle size of 20-30 μm (purity 99.99%), according to Weigh at a weight ratio of 89.8:10:0.2, ball mill for 4 hours under the protection of inert gas (Ar gas) and mix evenly, then place it in a rectangular high-strength, high-temperature-resistant and insulating mold of 800mm×580mm. Sintering with fixed pulse current and fixed direct current dual mode. Pre-compact and evacuate to 5×10 -4 Pa, start direct current direct heating sintering, the direct current density is 2.80mA / mm 2 , heat up to 1200°C, hold for 8 minutes, during which the pressure is continuously increased from 10MPa to 30MPa; mainta...

Embodiment 2

[0046] Sintering mode: variable voltage type, variable frequency variable amplitude pulse current and fixed direct current dual mode sintering, using devices such as figure 1 As shown, the operation steps are as follows figure 2 shown.

[0047] W powder (purity 99.99%) with an average particle size of 0.5-30 μm and Ti powder (purity 99.99%) with an average particle size of about 30 μm were weighed in a ratio of 80:20 by weight, in an inert gas (Ar gas) After ball milling under protection for 5 hours to mix evenly, place it in an 800mm×580mm rectangular high-strength, high-temperature-resistant and insulating mold. Sintering with variable frequency and variable amplitude pulse current and fixed direct current dual mode. Pre-compacted and evacuated to 3.2 x 10 -4 Pa, ion sintering at a temperature of 1400°C, where the pulse current density ranges from 11.67mA / mm 2 increased to 14.58mA / mm 2 , and the frequency is reduced from 82Hz to 65Hz, the duty cycle is constant at 89%,...

Embodiment 3

[0049] Sintering mode: variable voltage type, fixed pulse current and variable direct current dual mode sintering, using devices such as figure 1 As shown, the operation steps are as follows figure 2 shown.

[0050] W powder (purity 99.99%) with an average particle size of 0.5-30 μm, TiH with an average particle size of 10-30 μm 2 powder (purity 99.99%), weighed in a ratio of 90:10 by weight, ball milled for 7 hours under the protection of an inert gas (Ar gas) and mixed evenly, then placed in a rectangular high-strength, high-temperature-resistant and insulating mold of 800mm × 580mm Inside. Using fixed pulse current and variable direct current dual mode sintering, pre-compacted and vacuumed to 2.5×10 -4 Pa, turn on the DC and pulse current source, when the DC voltage is fixed at 400V, the current density changes from 2.81mA / mm over time 2 Slowly change to 3.31mA / mm 2 , at the same time, the pulse current frequency is 80Hz, and the density is 12.71mA / mm 2 , the duty cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com