A sheet metal positioning device on a bending machine

A technology of positioning device and bending machine, applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of difficult to overcome the impact of sheet metal, the influence of gear positioning accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

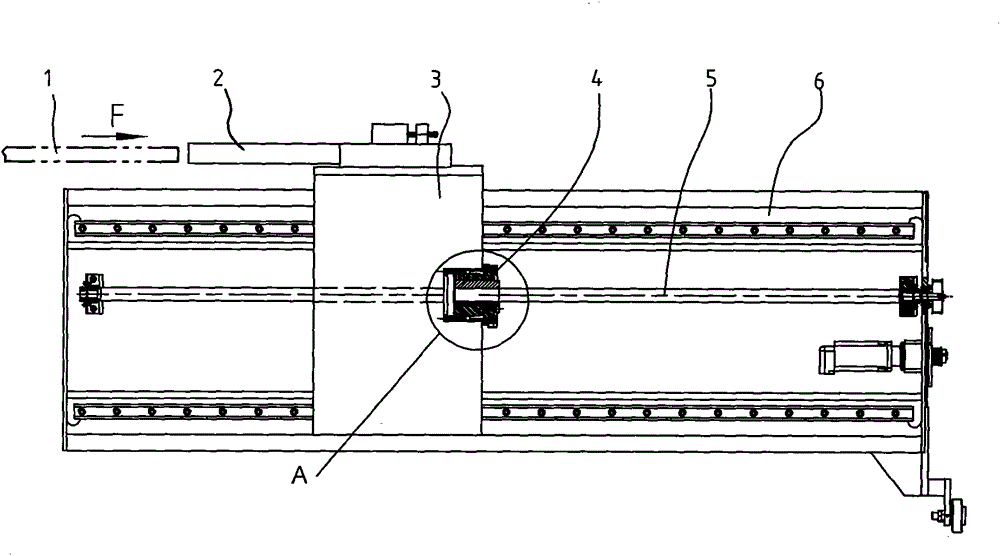

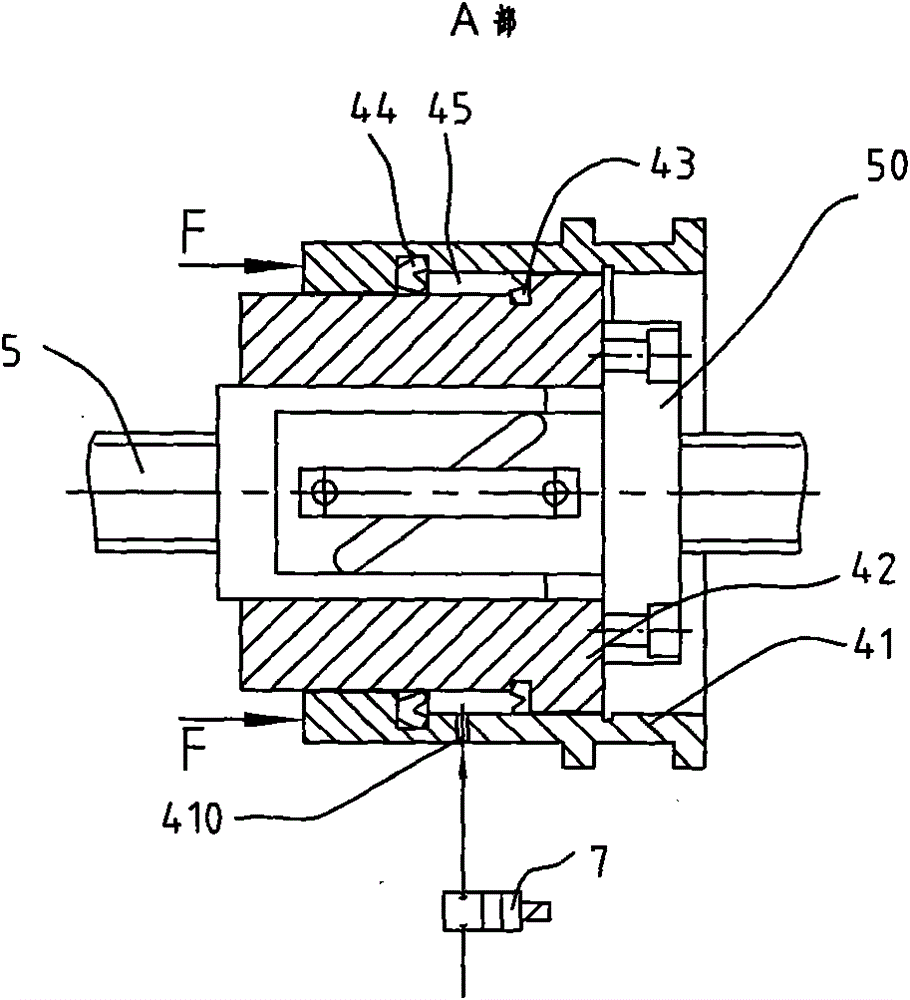

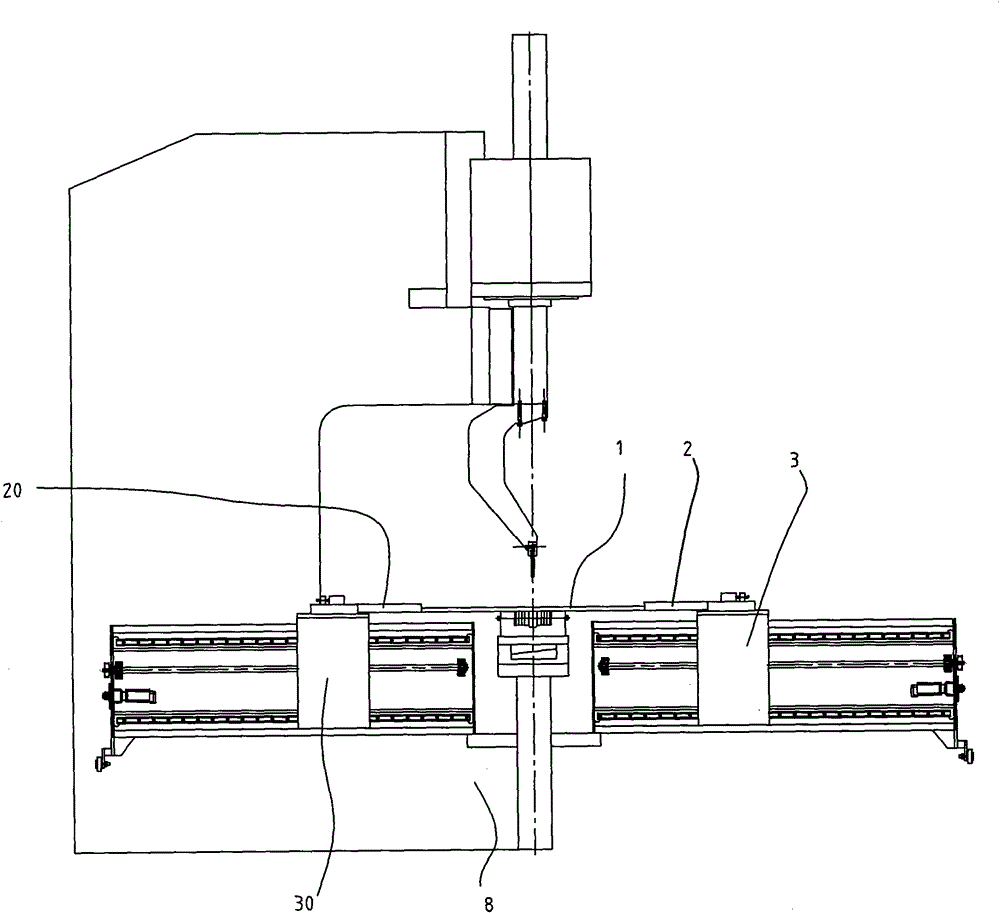

[0013] The present invention as figure 1 , 2 , 3, set at the front and / or rear of the bending machine 8 workbench, including a bracket 6, a moving frame 3, a screw rod 5 arranged on the bracket 6 for driving the moving frame 3 to move forward and backward, and a finger 2 and a pneumatic buffer compensation device 4; the finger 2 is arranged on the moving frame 3, and the working surface of the finger 2 faces the blade of the bending machine 8; the moving frame 3 passes through the pneumatic buffer compensation device 4 links to each other with described screw mandrel 5.

[0014] The pneumatic buffer compensation device 4 includes a screw nut 50 for screw connection with the screw rod 5 , a piston 42 sleeved outside the screw nut 50 and a cylinder sleeve 41 sleeved outside the piston 42 The cylinder liner 41 is fixedly connected to the moving frame 3; there is a pressure air cavity 45 between the cylinder liner 41 and the piston 42, which can make the moving frame 3 perform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com