Upper cover plate sealing device of full automatic sewage removing machine

A sealing device, fully automatic technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of short service life, cumbersome installation and disassembly, easy damage to the gasket, etc., to enhance the static sealing performance, installation and maintenance. The process is simple and the effect of ensuring the sealing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

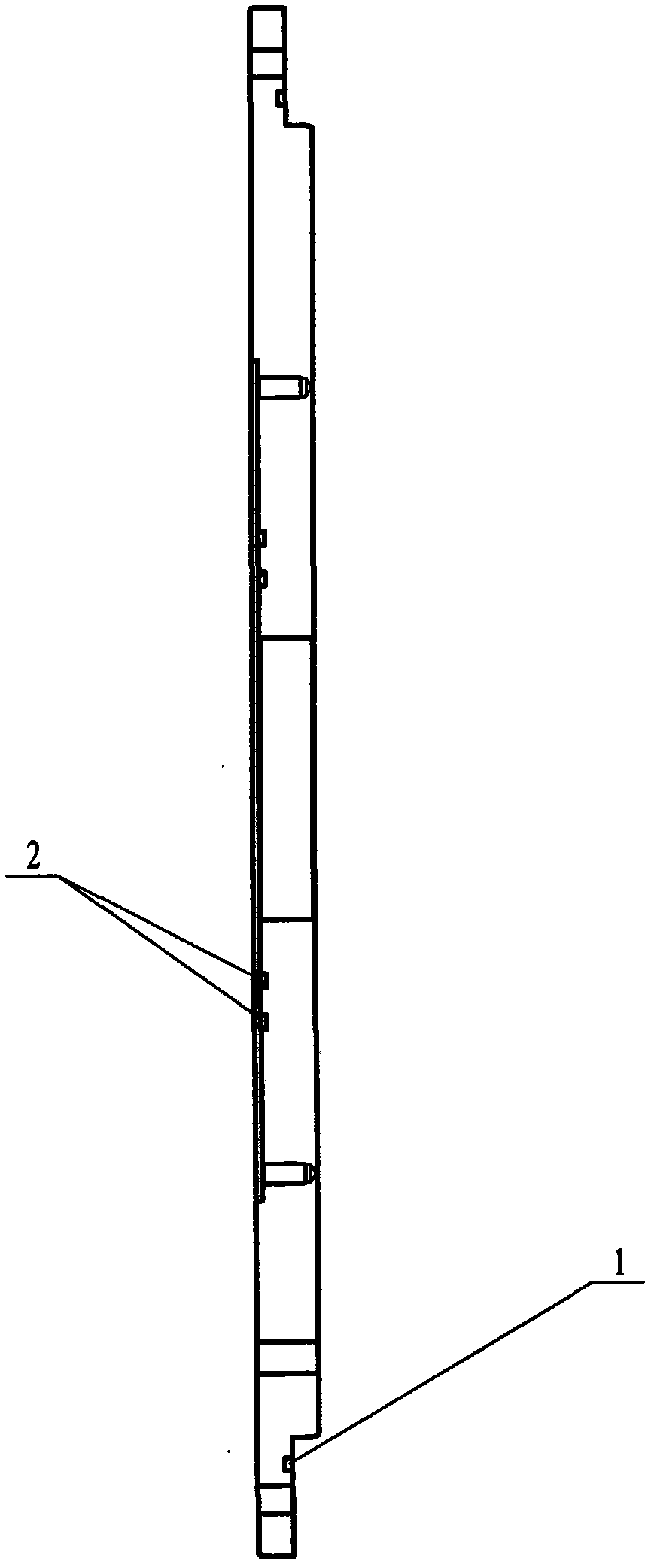

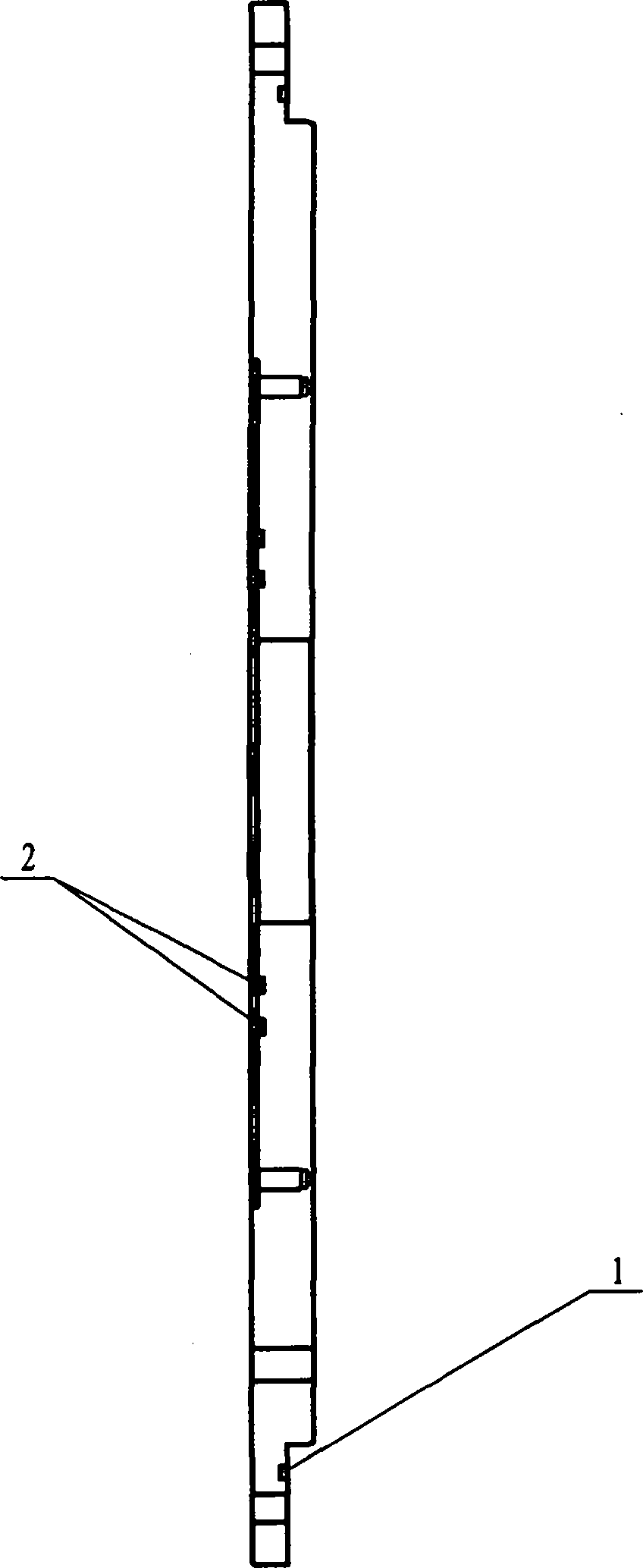

[0011] Concrete embodiment of the present invention is shown in accompanying drawing, now with reference to figure, be specifically described as follows:

[0012] As shown in the figure, three O-ring grooves are opened at the upper cover of the automatic sewage decontamination machine. The position of the second track and the third track is at the joint between the top of the upper cover plate and the connecting seat of the upper reducer, that is, the two O-ring grooves 2 of the upper cover plate and the connecting seat of the upper reducer. There is a small chamfer on the inner side of the three O-ring grooves to give the O-ring deformation and outflow space. When the O-ring is worn, the supplementary characteristics of the O-ring can ensure that the sealing ring will not be caused by wear and corrosion. The sealing effect is reduced, and the sealing time and product service life are prolonged.

[0013] Insert the O-ring through the O-ring groove. When the equipment is press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com