Hydraulically driven low-temperature reciprocating pump capable of reducing influence of low temperature on piston rod seal

A piston rod and reciprocating pump technology, applied in the field of hydraulically driven low-temperature reciprocating pumps, can solve problems such as seal failure, hydraulic oil leakage, and temperature reduction of the piston rod surface, and achieve the effects of ensuring the life of the seal, preventing frosting, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

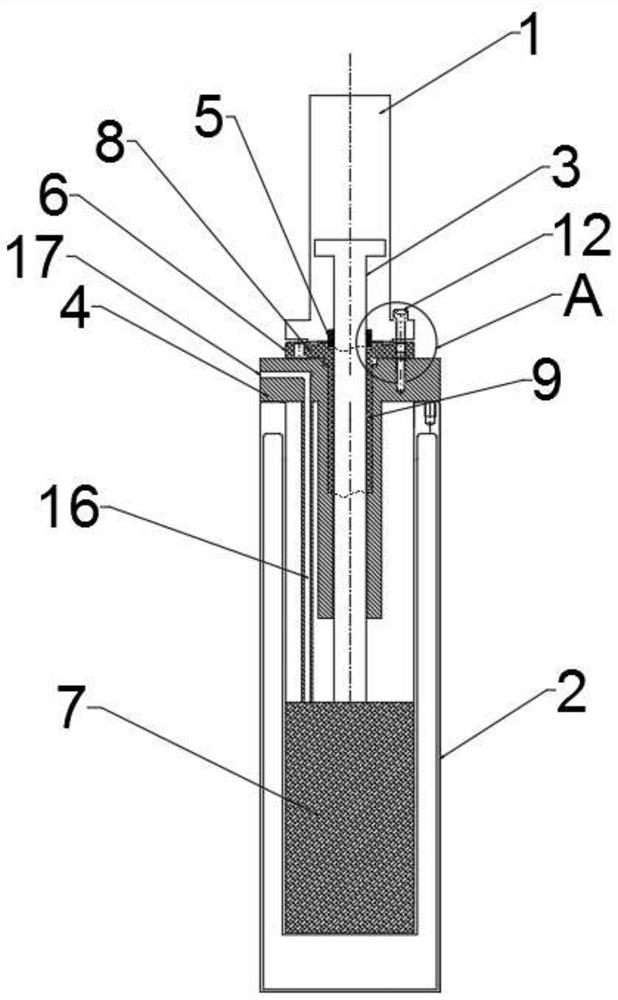

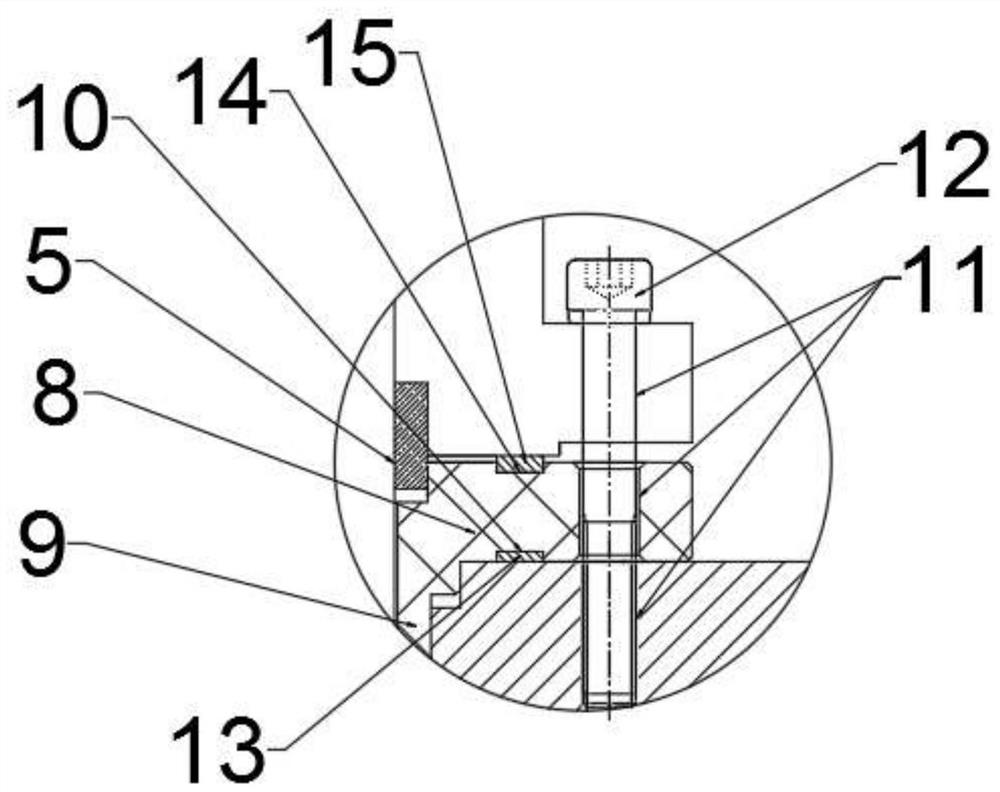

[0020] refer to figure 1 , the present invention provides a technical solution: a hydraulically driven low-temperature reciprocating pump that can reduce the impact of low temperature on the seal of the piston rod, including a cylinder body 1, a pump body 2 and a piston rod 3, and the pump body 2 includes a vacuum storage tank 7 and a pump The body end cover 4 and the vacuum storage tank 7 are equipped with cryogenic media with extremely low temperature, such as liquid nitrogen or liquid methane and other media; the opening of the pump body 2 is provided with a pump body end cover 4; the pump body end cover 4 is fixedly connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap