Reverse-osmosis apparatus

A technology of reverse osmosis and equipment, applied in the direction of reverse osmosis, semi-permeable membrane separation, membrane, etc., can solve the problems of efficiency deterioration and concentration increase, and achieve the effects of reducing pressure loss, favorable efficiency, and saving pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

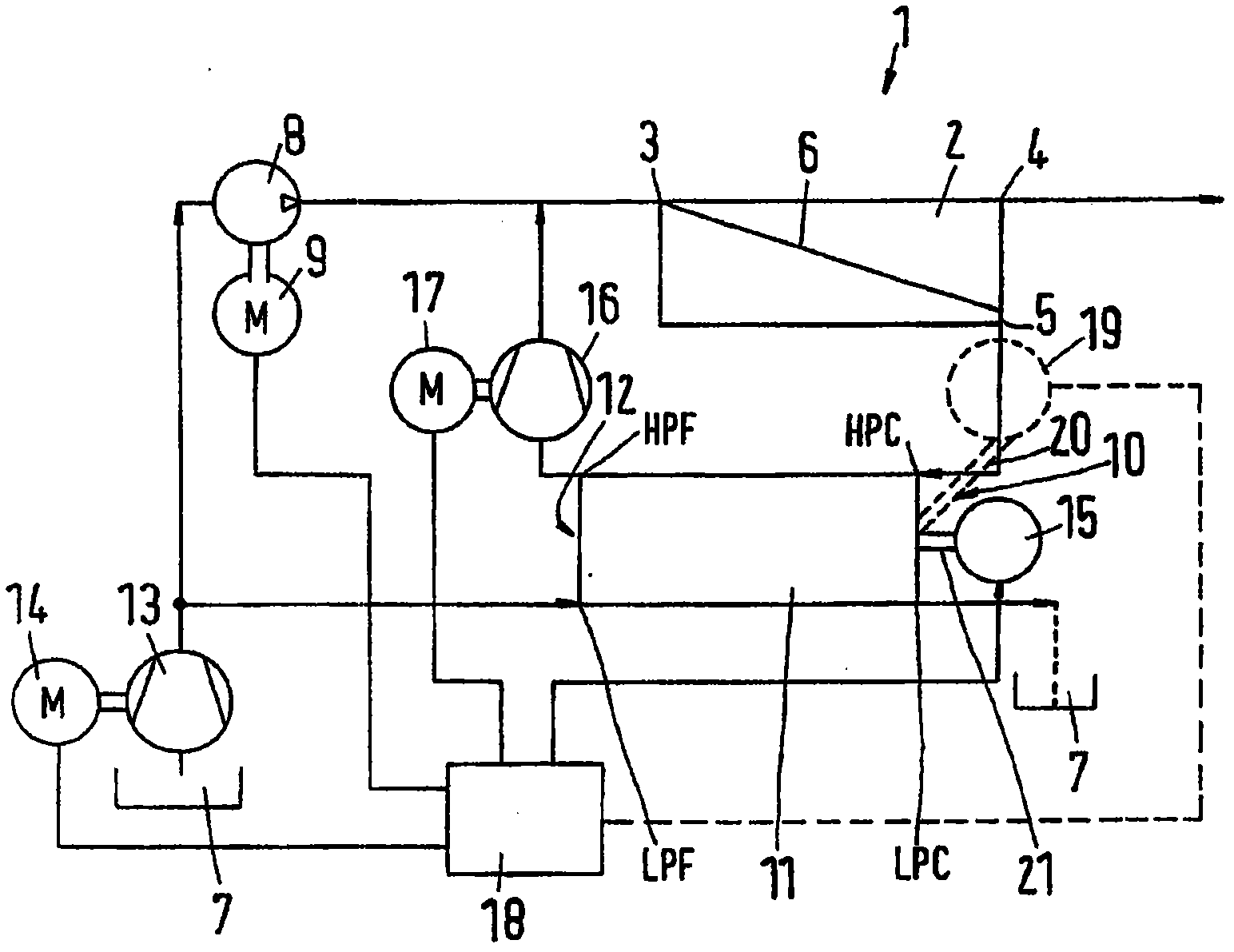

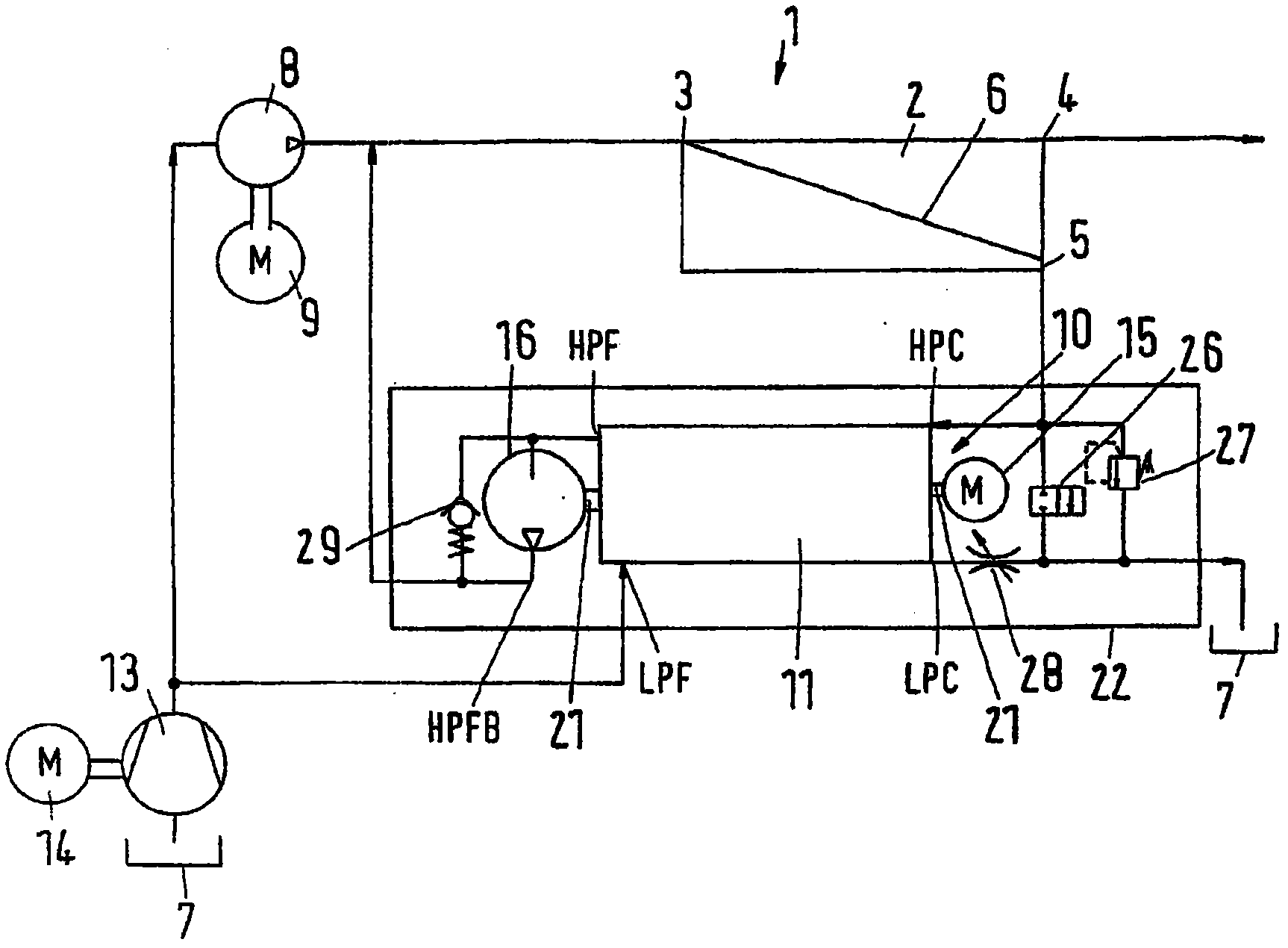

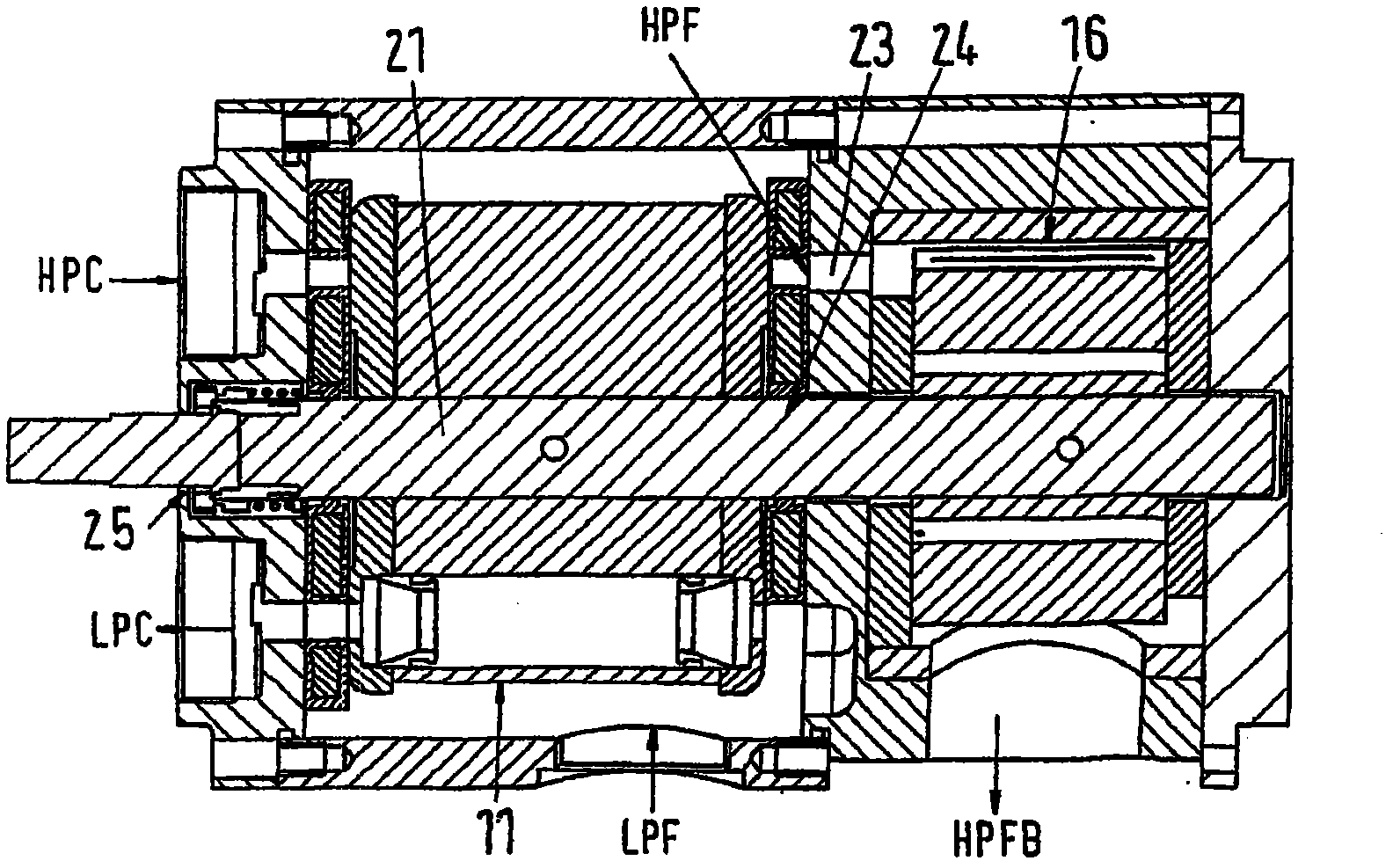

[0028] figure 1 A reverse osmosis plant 1 is schematically shown, which may also be called a reverse osmosis device or a reverse osmosis structure.

[0029] The reverse osmosis plant has a membrane unit 2 with an inlet 3 , a permeate outlet 4 and a concentrate outlet 5 . A membrane 6 is arranged between the inlet 3 and the permeate outlet 4 .

[0030] The membrane unit 2 is supplied with water from a supply 7 , for example the sea, by means of a high-pressure pump 8 driven by a motor 9 . The high-pressure pump 8 can be, for example, a piston pump. The motor 9 can be designed as an electric motor, which is controlled by a frequency converter. Thus, the high-pressure pump 8 can be operated with a variable rotational speed and thus with a variable delivery capacity.

[0031] The water in the reserve 7 is called "feed water" for simplicity.

[0032] The concentrate outlet 5 is connected to the concentrate side 10 of the pressure exchanger 11 , to be precise with the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com