Three-section combined type ultraprecise positioning table and positioning method thereof

A positioning method and ultra-precise technology, which can be applied to parts and instruments of instruments, etc., can solve the problems of low positioning accuracy and small working stroke, and achieve the effect of shortening positioning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solution of the present invention, a further detailed description is given below in conjunction with the accompanying drawings.

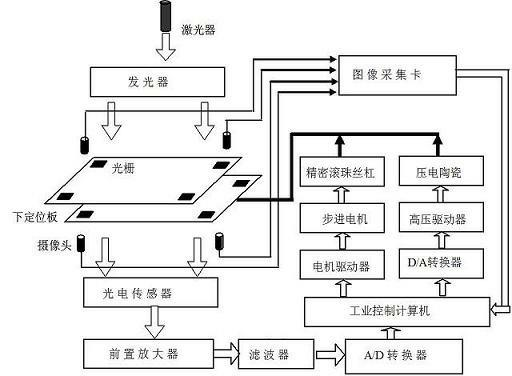

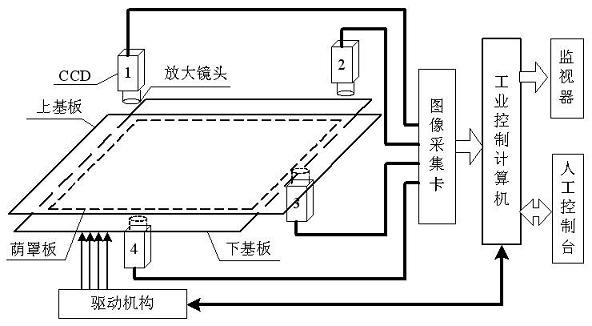

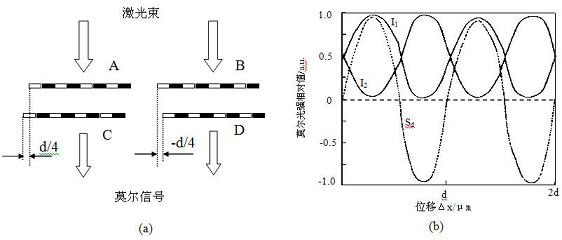

[0020] The combined ultra-precision positioning table of the present invention is as figure 1 As shown, it includes laser grating detection system, computer vision detection system, photoelectric detection circuit, coarse positioning mechanism, micro-positioning mechanism, drive system and microcomputer control system, etc., in order to realize the three-stage combination of coarse positioning, fine positioning and ultra-precision positioning Combined positioning.

[0021] The rough positioning mechanism completes the steps of rough positioning, which can realize lateral movement, longitudinal movement and plane rotation movement, that is, movement in three directions of X, Y and θ, among which the linear movement is controlled by a pulse subdivision driving high-precision stepping motor, And thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com