Self-cleaning device for dirt between barrels of washing machine

A washing machine and self-cleaning technology, which is applied in the field of washing machines, can solve the problems of secondary pollution and the inability to clean the dirt in the outer barrel well, and achieve good effect, solve the problem of secondary pollution, and be convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with the accompanying drawings, the device for self-cleaning dirt between washing machine barrels of the present invention will be further described in detail with regard to two embodiments of the present invention.

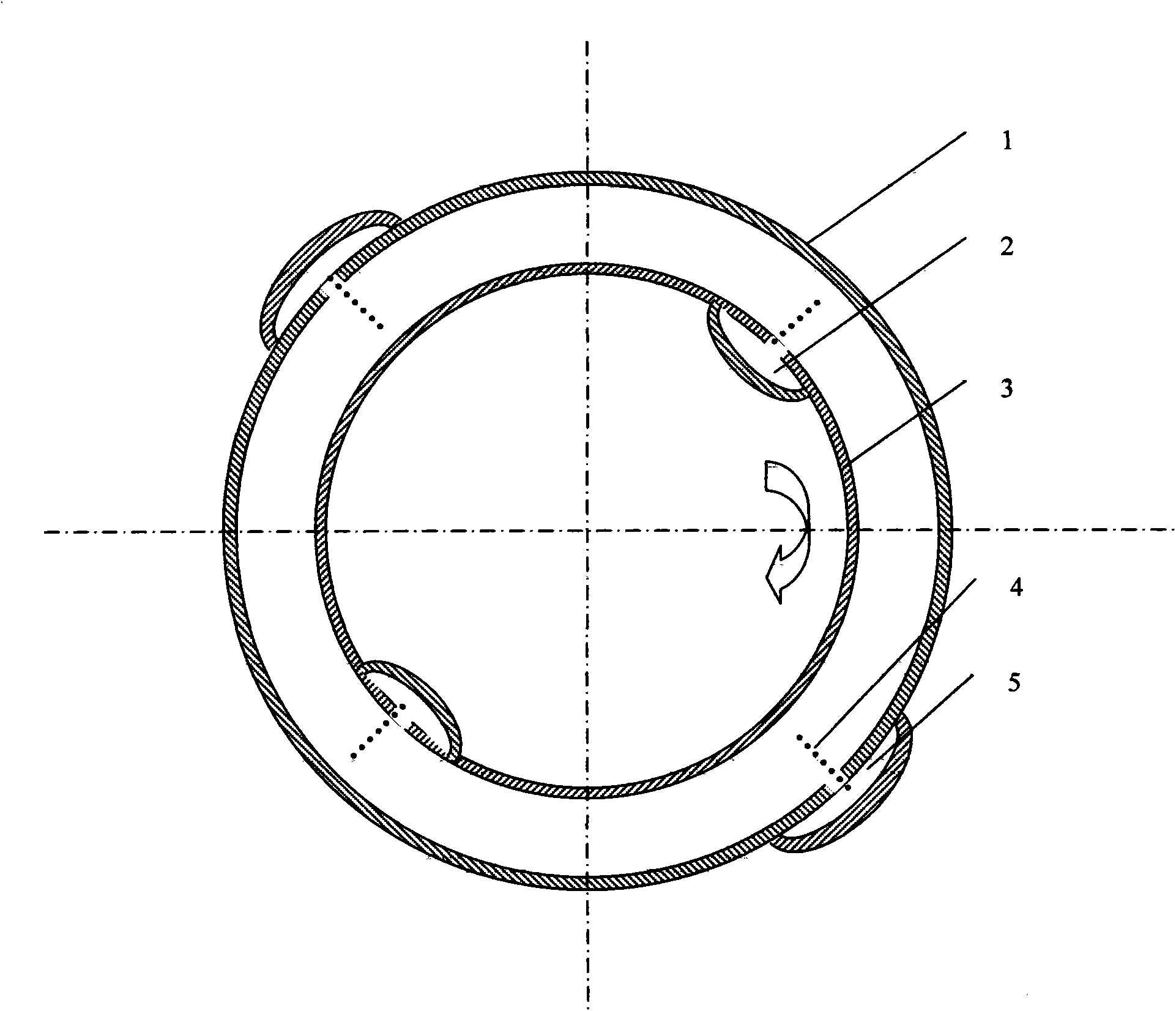

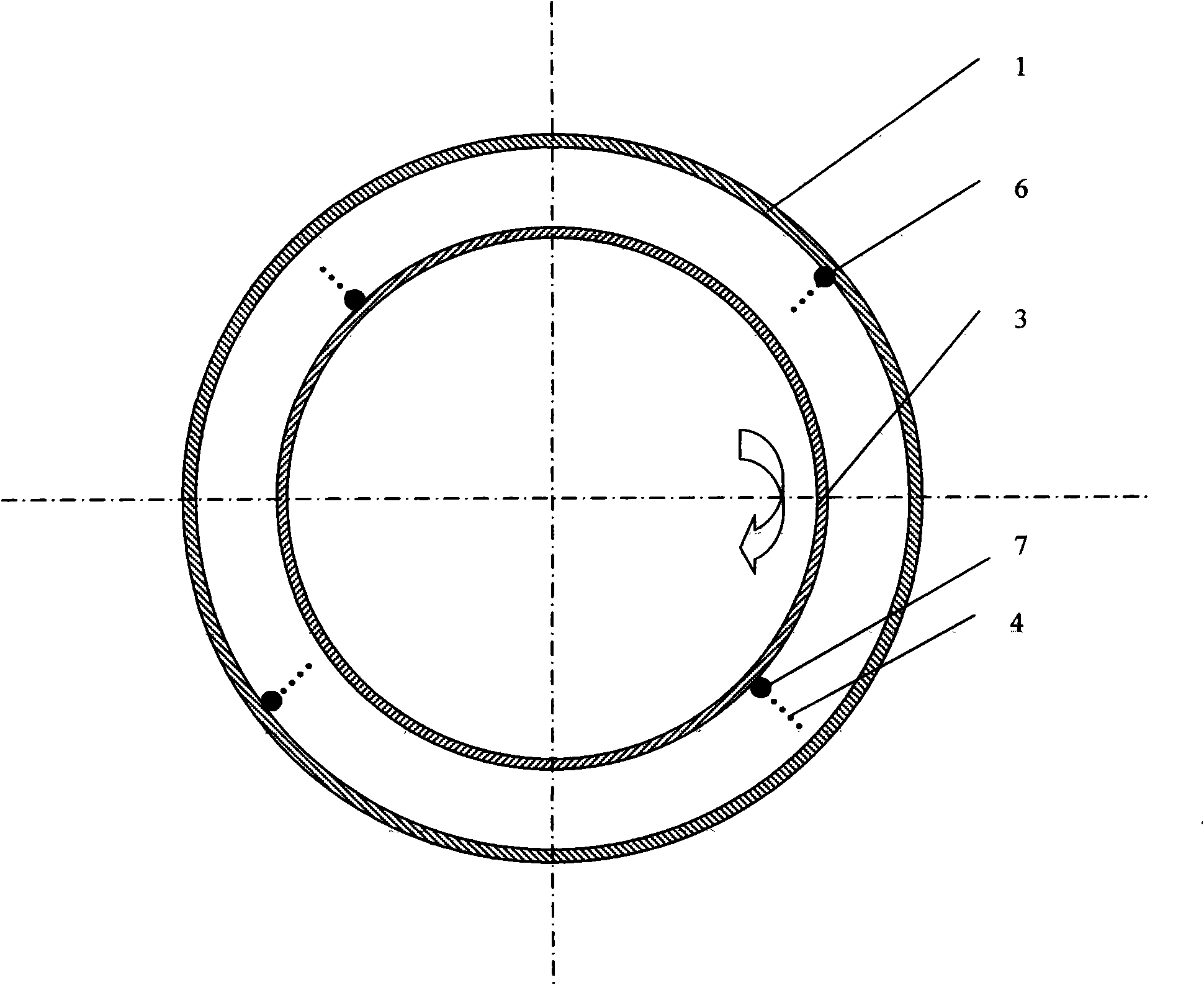

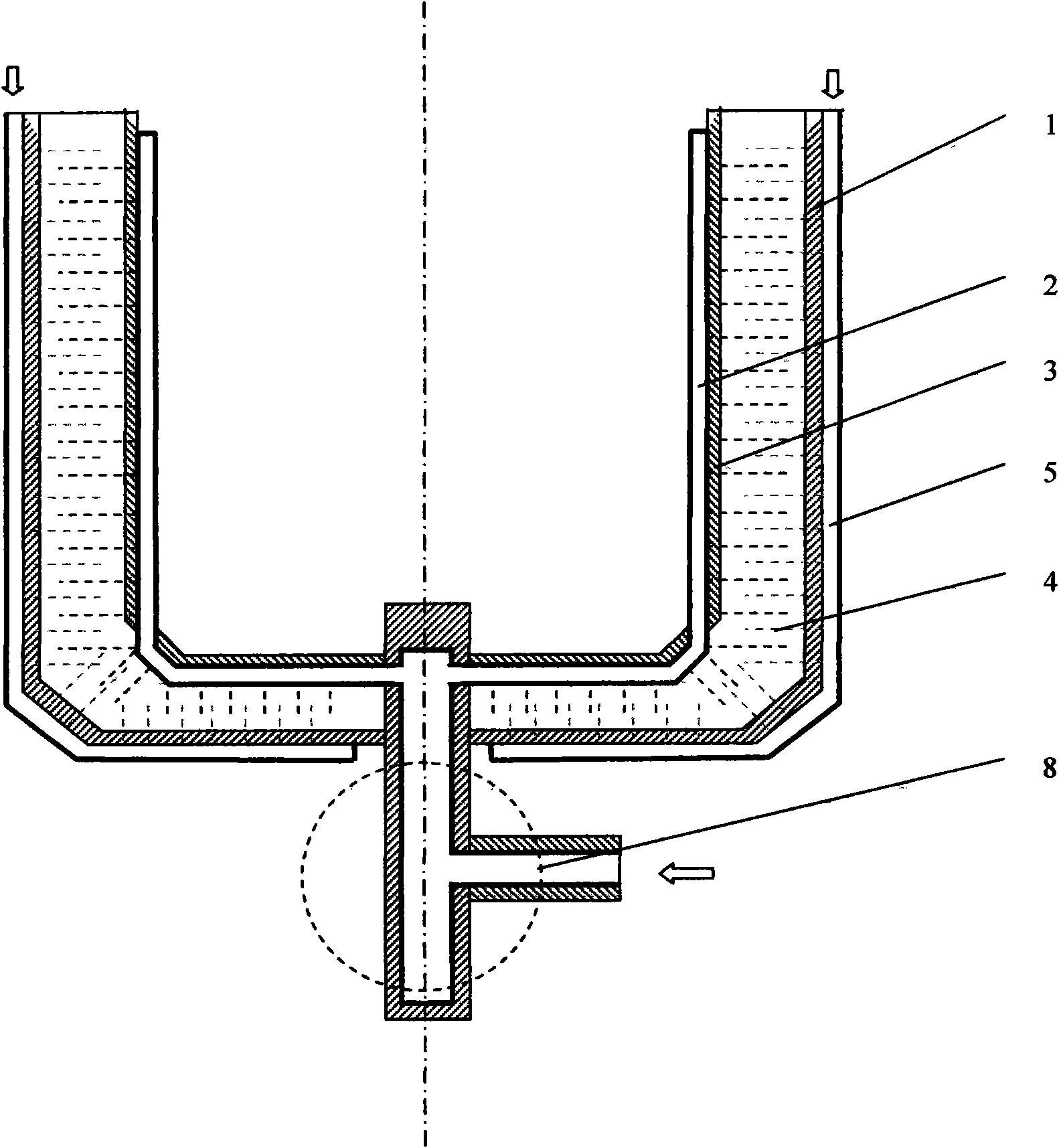

[0029] 1 and 1b in the figure are the outer barrel of the washing machine, 2 and 2b are the built-in inner barrel water flow channel when the water flow channel is directly integrated with the inner barrel when the water flow channel is manufactured, 3 and 3b are the inner barrel of the washing machine, and 4 and 4b are the liquid sprayed from the small holes. A water curtain with a certain pressure, 5 and 5b are the built-in outer barrel water flow channel when the water flow channel is directly integrated with the outer barrel when the water flow channel is manufactured, 6 is the external outer barrel water flow channel when the water flow channel is set with another pipeline, and 7 is When the water flow channel is provided with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com