Printing device and printing method

A technology of printing device and printing table, which is applied in the directions of printing device, printing, printing machine, etc., can solve the problems of high cost and complicated device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

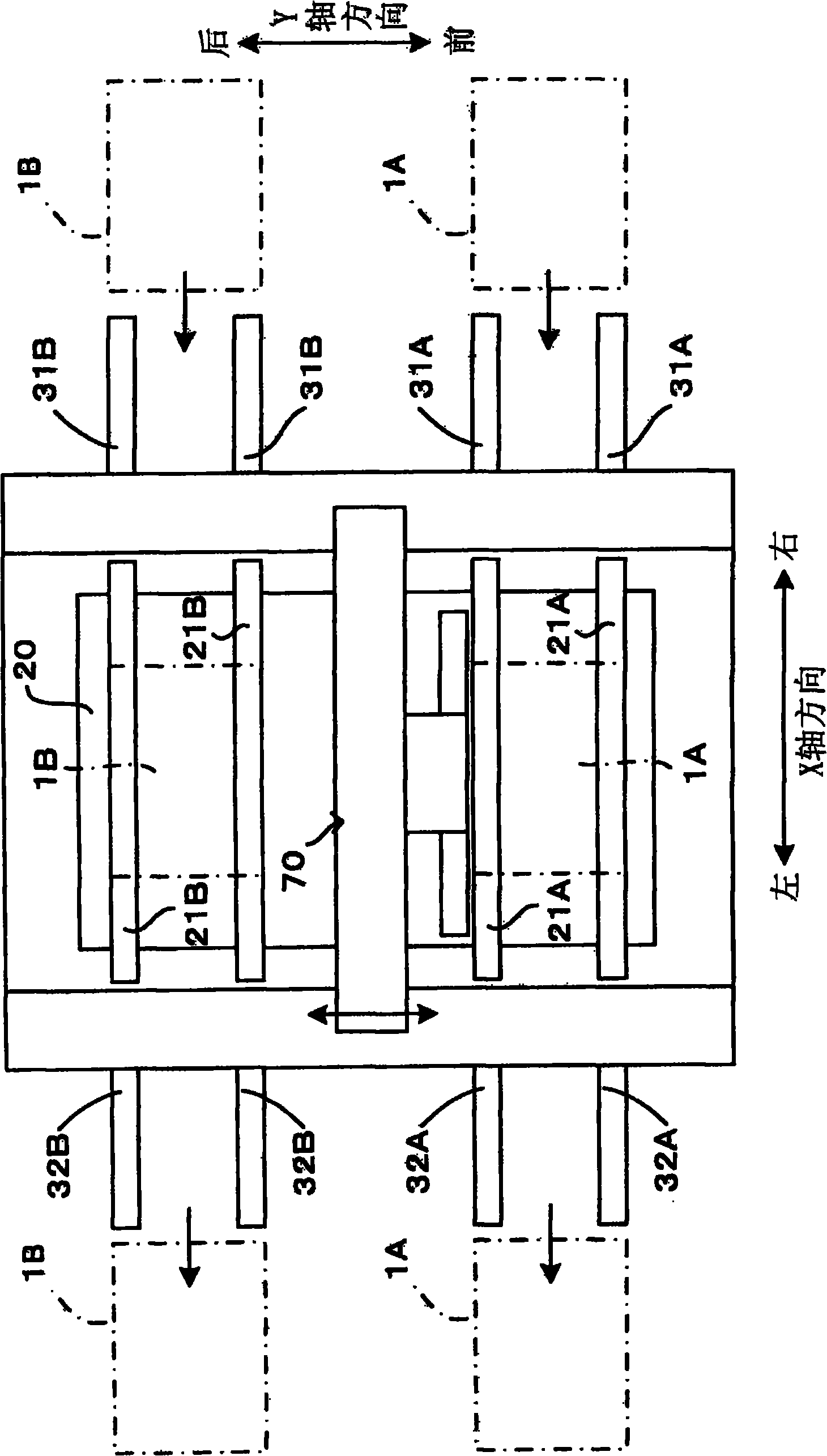

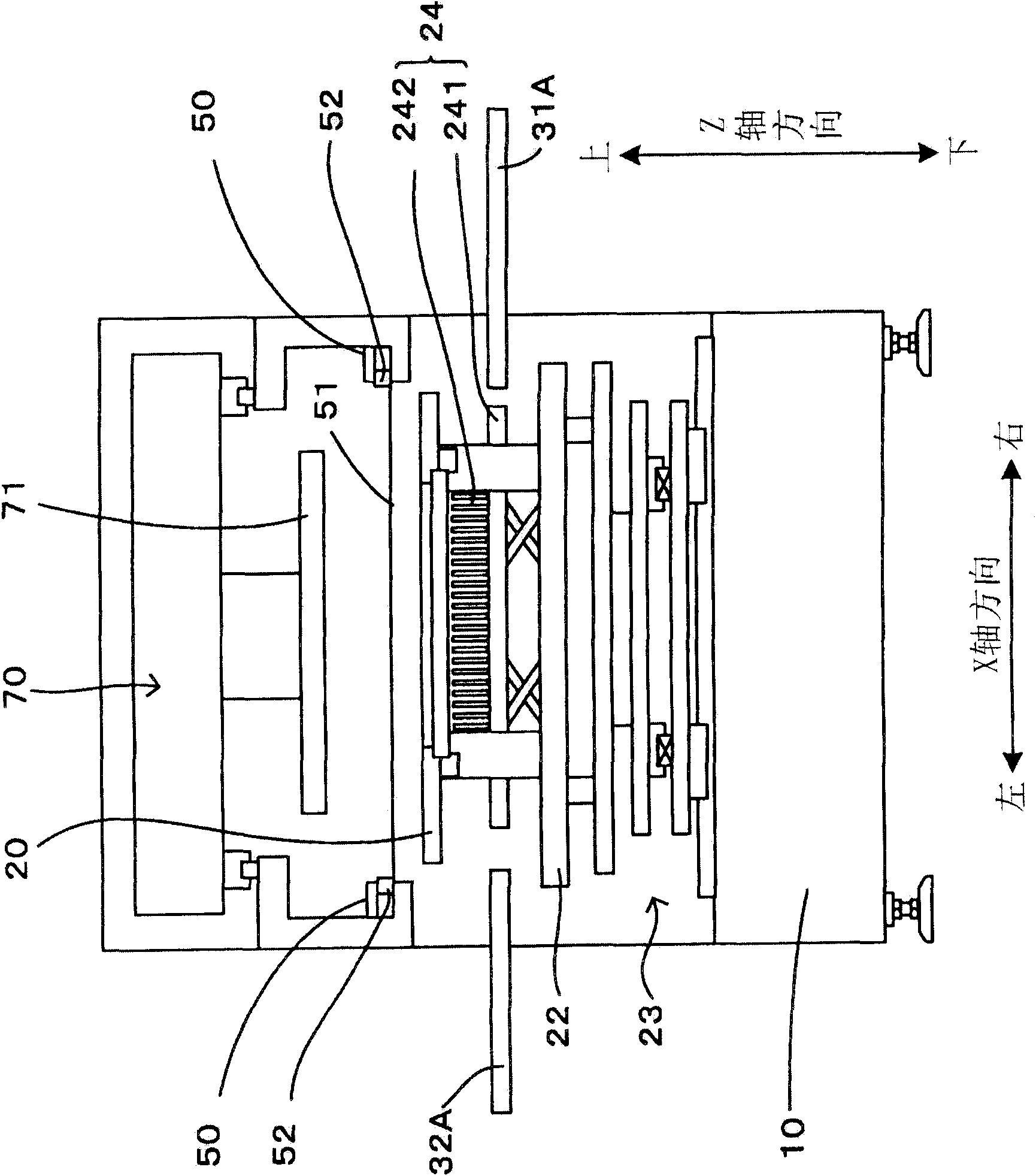

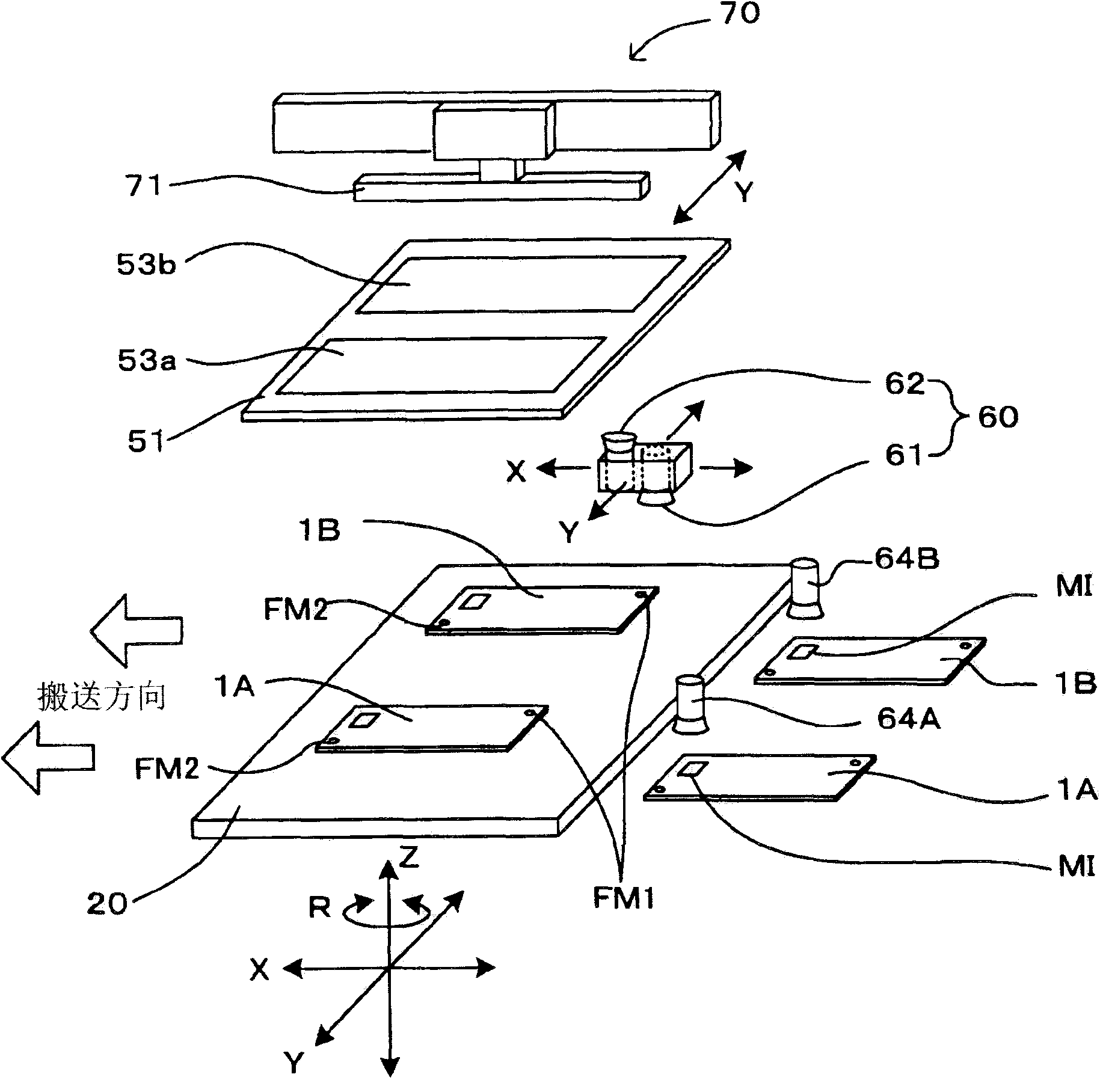

[0027] figure 1 It is a plan view showing one embodiment of the printing apparatus according to the present invention, and shows a schematic configuration of the printing apparatus in a state where no mask is provided. and, figure 2It is a side view showing a schematic configuration of a printing apparatus in a state where a mask is installed. image 3 It is a perspective view schematically showing the positional relationship of a substrate, a mask, and a squeegee. Figure 4 It is a block diagram showing the main electrical configuration of the printing device. In this printing device, a printing table 20 is provided on a base 10 . The printing table 20 has a substrate 1A on the base 10 from figure 1 A pair of conveying parts 21A, 21A that convey from the lower right side to the lower left side. And, according to the driving instruction from the printing table control part 43 of the control unit 40, the conveying part 21A is operated, and the substrate 1A is conveyed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com