Device and method for assisting gas metal arc welding by using externally applied magnetic fields

A technology of melting pole gas and external magnetic field, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of signal interference, narrow applicable current range, and limited promotion, so as to improve the short-circuit transition welding process , device and method are simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

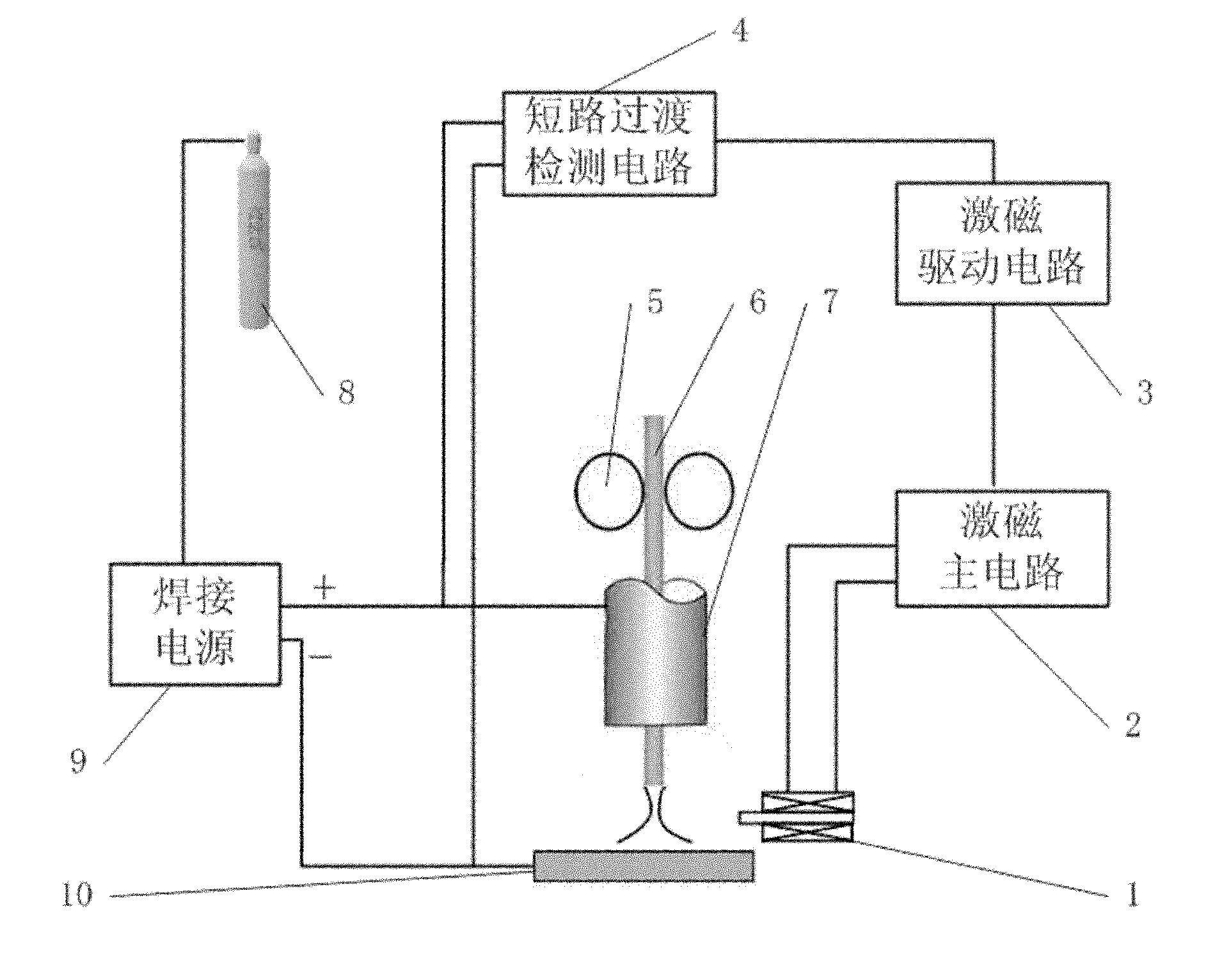

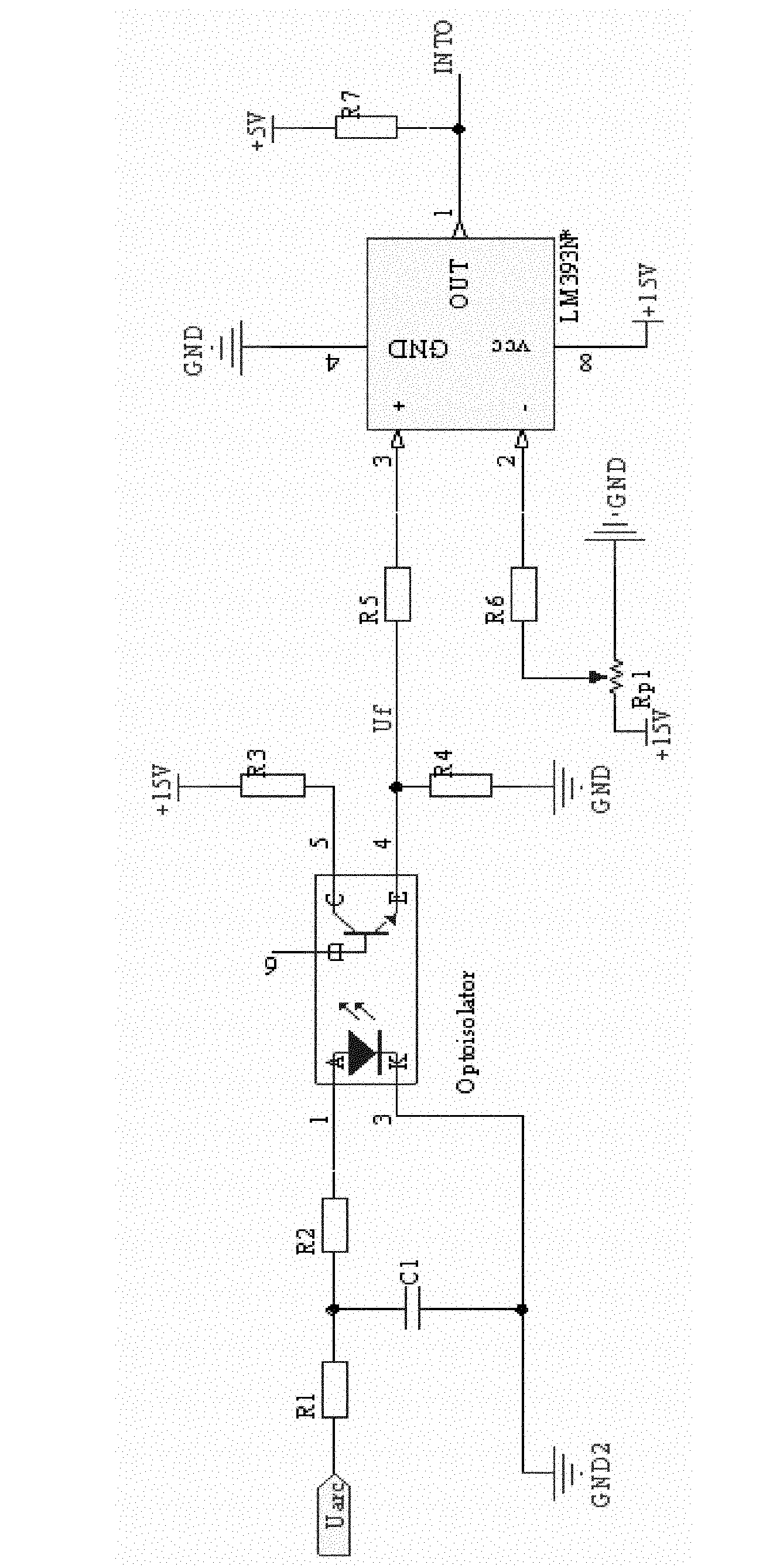

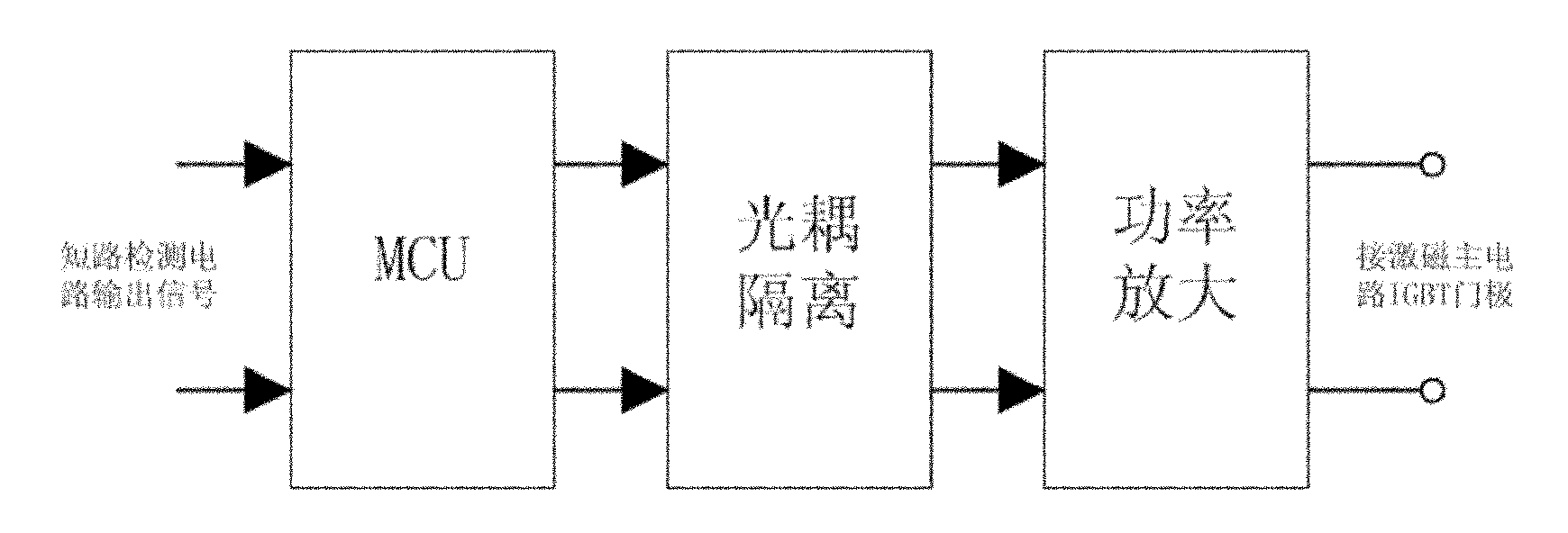

[0043] The specific embodiment of the present invention sees Figure 1-Figure 4 , this embodiment includes a welding power source 9, a wire feed motor 5, a welding wire 6, a conductive tip 7, a shielding gas cylinder 8, and the necessary equipment for conventional MIGMA welding of a welding workpiece 10, and also includes a short-circuit transition detection circuit 4, an excitation drive Circuit 3, excitation main circuit 2 and magnetic head device 1; the positive pole of the welding power supply 9 is connected to the conductive tip, and the negative pole is connected to the welding workpiece 10, and at the same time, two wires are respectively drawn from the positive pole and the negative pole of the welding power supply 9 to the short-circuit transition detection circuit 4 The input end of the short-circuit transition detection circuit 4 is connected to the input end of the excitation drive circuit 3, the output of the excitation drive circuit 3 is connected to the input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com