Improvements in or relating to stitched perforated sheet materials

A thin, non-perforated technology, applied in the seams of textile materials, thin material processing, and the production of furniture covers, etc., can solve the problem of destroying the aesthetic effect of stitched materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

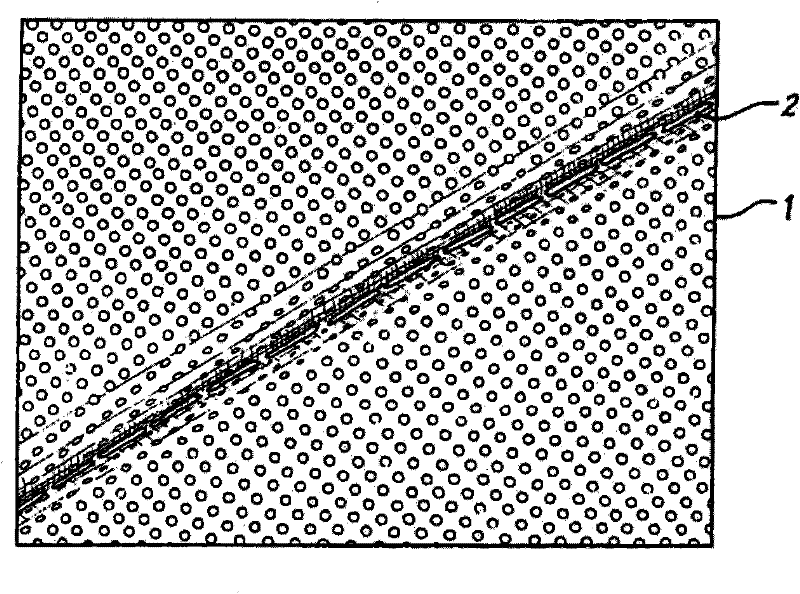

[0020] Figure 1 shows a sheet 1 of perforated leather of the prior art, in which stitch threads 2 penetrate the material. The material 1 is perforated in a regular pattern of perforations evenly spaced on parallel spaced straight lines. By using a conventional sewing machine, a stitch line 2 through the material is formed. The stitches tend to bend and travel between perforations in the material. Therefore, the stitch line is not smooth or straight, and this spoils the appearance of the stitched material.

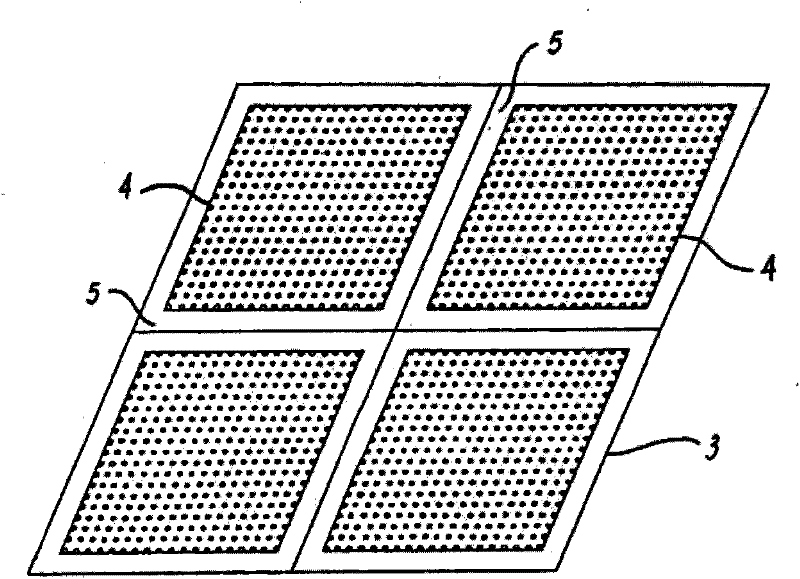

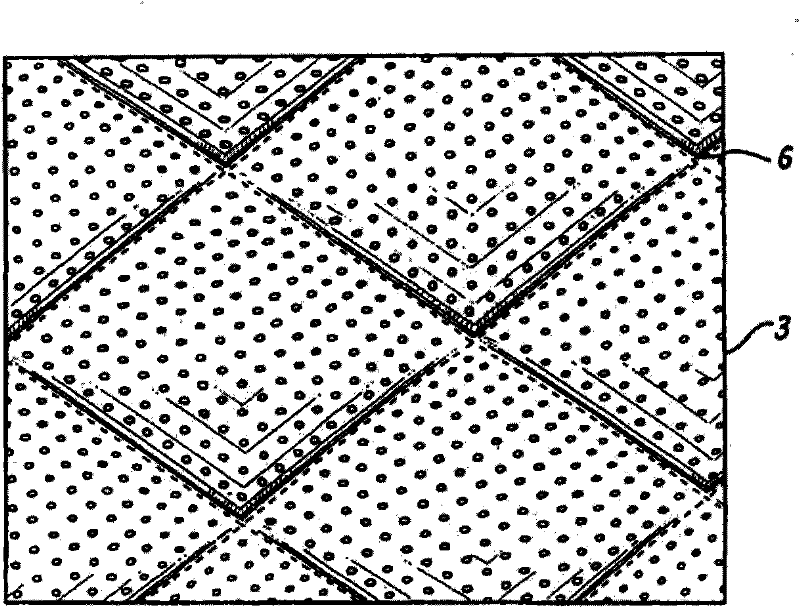

[0021] See now figure 2 with image 3 The method according to the invention involves supplying a sheet 3 of material, in this case leather, which has one or more perforated areas 4 separated by non-perforated areas 5. In this embodiment, each perforation area is substantially diamond-shaped, formed by a series of parallel and evenly spaced perforation lines. The unperforated area 5 includes a strip of unperforated material extending between the perforated areas to form a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com