White organic electroluminescence device based on color conversion and manufacturing method thereof

An electroluminescent device and color conversion technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of different aging rates of luminescent groups, affecting the operating life of devices, and chromaticity shifts, etc., to achieve The effects of chromaticity stability, low cost, and high outcoupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

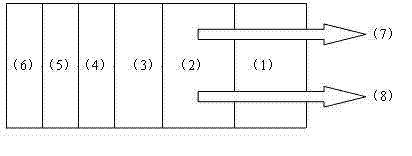

[0031] Below in conjunction with accompanying drawing, example is further described.

[0032] Such as figure 1 As shown, the white organic electroluminescent device in this example has the red fluorescent material MEH-PPV as the color conversion layer, which includes an ITO glass substrate (1), a color conversion injection layer (2), a hole transport layer (3 ), light emitting layer (4), electron transport layer (5), composite cathode layer (6), wherein the color conversion layer is MEH-PPV, and the light emitting layer is made of blue light theme material TBADN doped with 3.0wt% blue light material DSA- Ph, the electron transport layer material is Alq 3 .

[0033] The detailed steps and process of the preparation method of the white organic electroluminescence light-emitting device with the device structure are as follows:

[0034] a. Select an ITO glass substrate (1) that meets the requirements, its effective area is 5mm×5mm, and its surface resistance is 10Ω / □. After sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com