Method and sensor for detecting relative sliding velocity between plate and mould in stamping process

A technology of relative sliding and sliding speed, which is applied in the direction of devices using optical methods, can solve the problems of methods and sensors without sliding speed, and is not suitable for stamping and forming of sheet metal, so as to achieve strong anti-multipath effect, reduce interference, Ease of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

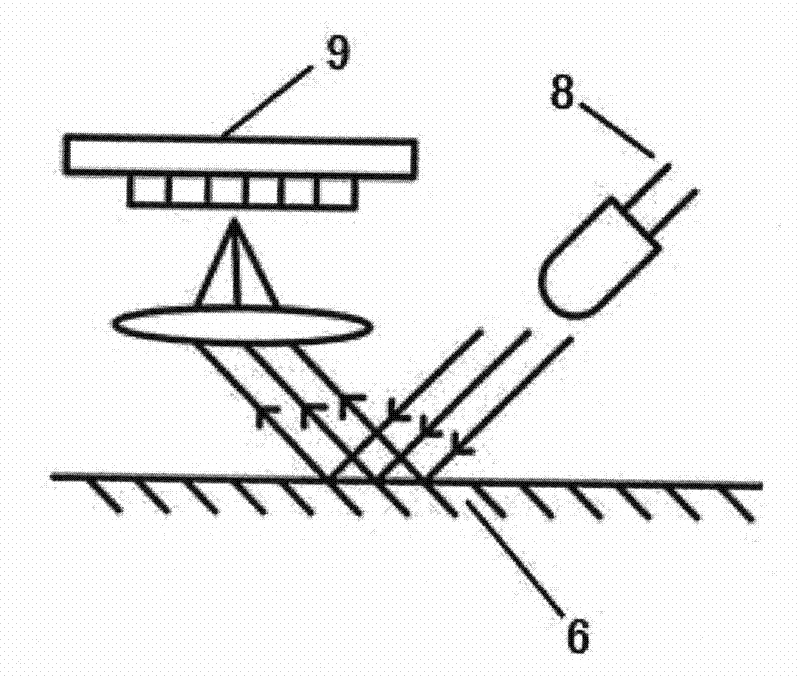

[0061] The sliding speed sensor is installed on the universal plate formability testing machine for deep drawing test detection, and the sliding speed of the flange part is detected during the deep drawing process.

[0062] First, put the detection sensor into the die, install the die on the test bench, then connect the detection sensor to the control box, and use the computer serial port to connect the control box to the computer (CPU). At the same time, connect the control box Power supply 16 ensures that the control box works. Drawing die and detection sensor installation holes such as Figure 7 As shown, the system is connected as shown in Figures 8 and 9.

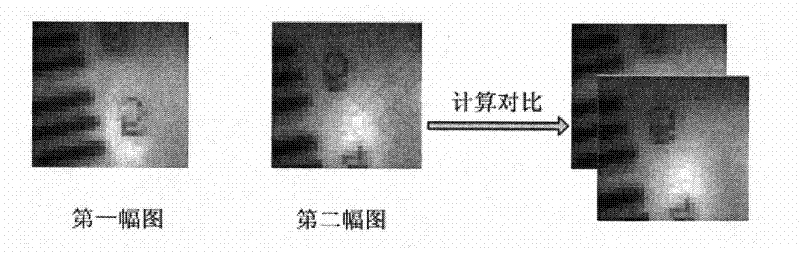

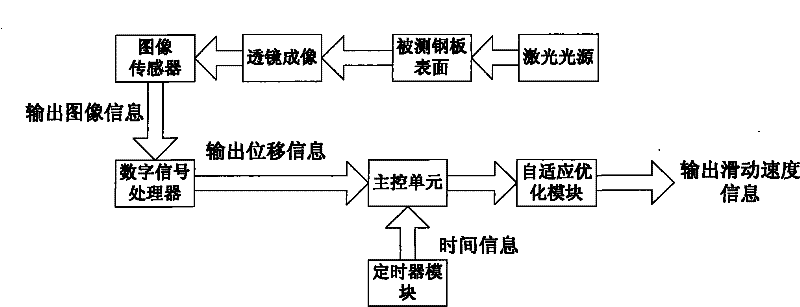

[0063] The detection sensor includes a main control unit (MCU) 5, a laser displacement detection unit 12 connected to the main control unit (MCU) telecommunication, and the main control unit (MCU) includes a communication module 2 connected by telecommunication, a storage module 1, An adaptive optimization module 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com