Water and air double-cooled hydraulic cylinder

A hydraulic cylinder and water-gas technology, which is applied in the direction of fluid pressure actuation device, etc., can solve the problems of short service life, simple structure of oil cylinder cooling jacket, poor cooling effect, etc., so as to improve service life, good cooling effect and avoid premature damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

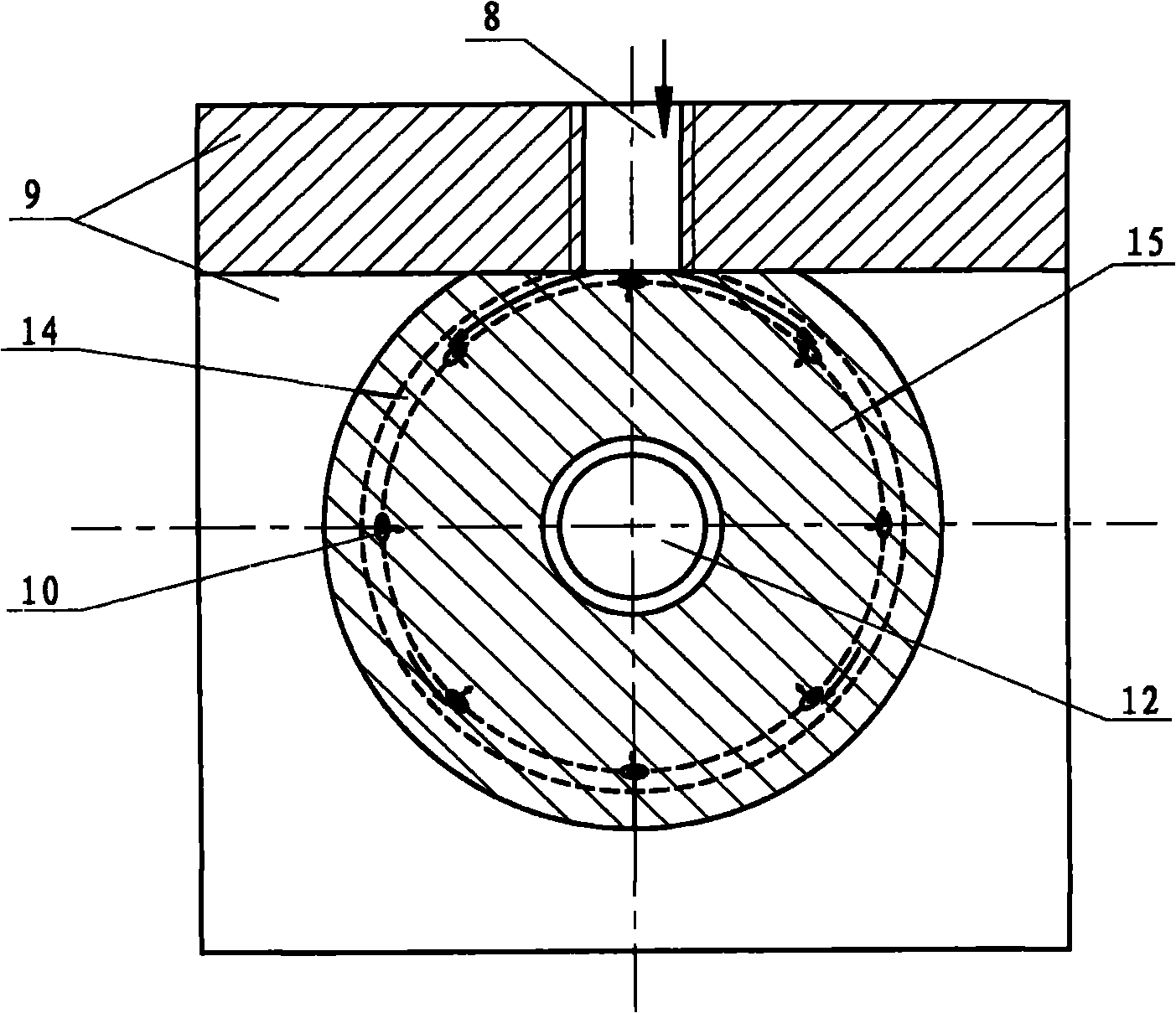

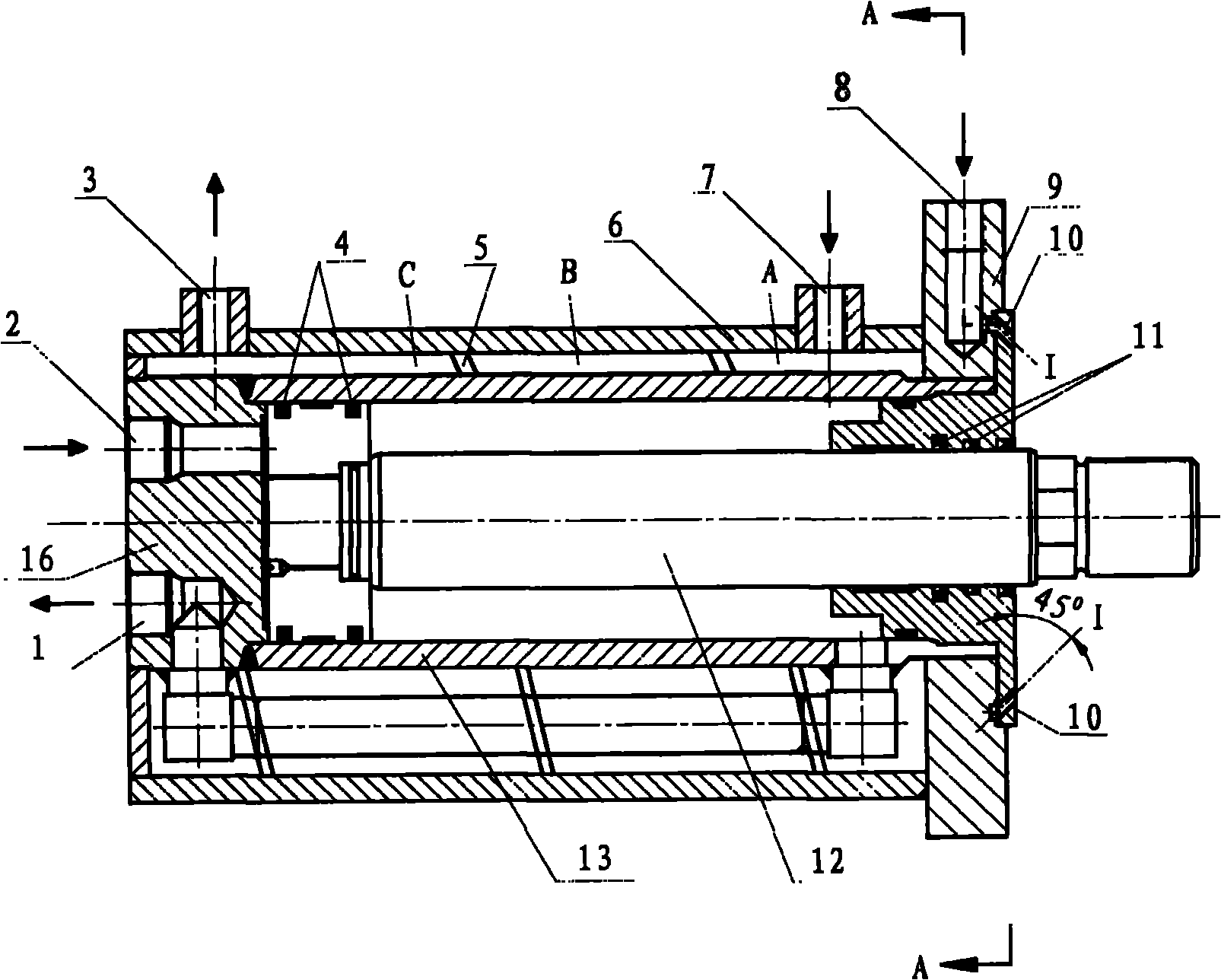

[0022] Now, embodiments according to the present invention will be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. Hereinafter, the embodiments are described in order to explain the present general inventive concept by referring to the figures.

[0023] Such as figure 1 and figure 2 As shown, the water-air double-cooled hydraulic cylinder for the sliding taphole of the converter in the exemplary embodiment of the present invention includes: a water-cooled spiral plate 5, a water-cooled jacket 6, an air-cooled end cover 9, a piston rod 12, an oil cylinder body 13, and an oil cylinder Shaft end sealing cover 15 and oil cylinder sealing cover 16.

[0024] In this embodiment, the water-cooling jacket 6 is roughly hollow cylindrical, and a water outlet 3 and a water inlet 7 separated from each other are provided on the cylinder, and the water inlet 7 is used to inject cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com