Method for grouting floor slab bushing hole reservation preembedding die and grouting die

A construction method and casing technology, applied in the direction of formwork/formwork/work frame, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of water leakage, large chisel area, poor force, etc., to avoid dislocation The effect of excessive error, accurate installation position and small operation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

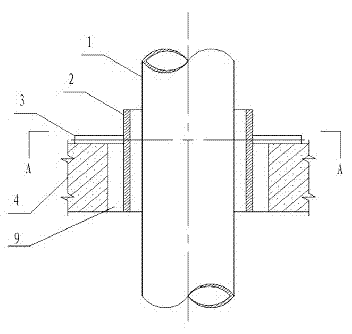

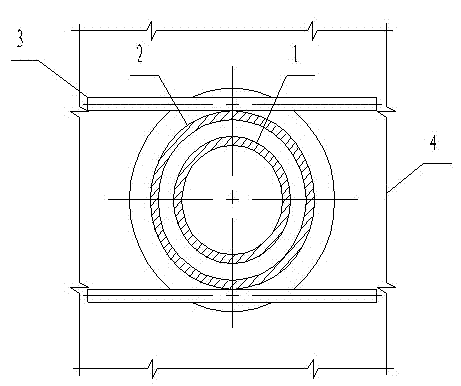

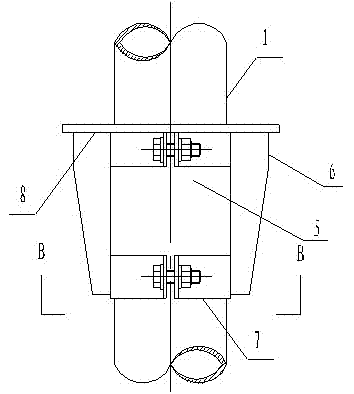

[0043] Pre-embedded grouting molds are reserved for floor casing holes, such as Figure 1 to Figure 5As shown, its structure is as follows: it is composed of a clamping cylinder body 5 and a plane template 8 fixed on the top of the clamping cylinder body. The clamping cylinder body 5 is an arc-shaped plate bent from a thin plate with a thickness S of 3 mm, including a combination The two standpipe wrapping plates forming a hollow cylinder and the snap ring connecting piece that fixes the two standpipe wrapping plates with open and close clamps, the snap ring link is the open and close snap ring 7, and the plane formwork on the top of the clamping mold cylinder 8 is made of a steel plate with a thickness S of 4mm according to the required size, including two flat formworks that are respectively fixed on the two riser wrapping plates and seamlessly spliced together. The flat steel plate of 40×4mm is used as the bottom of the plane formwork 8. The oblique support plate 6 reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com