System for lifting and sliding large-tonnage steel box girder in land area and shoal area and construction method thereof

A technology of steel box girder and large tonnage is applied in the field of lifting slip system, which can solve the problems of long construction period, low construction efficiency, high cost and high cost, and achieve the effect of shortening construction period, realizing lifting and installation, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

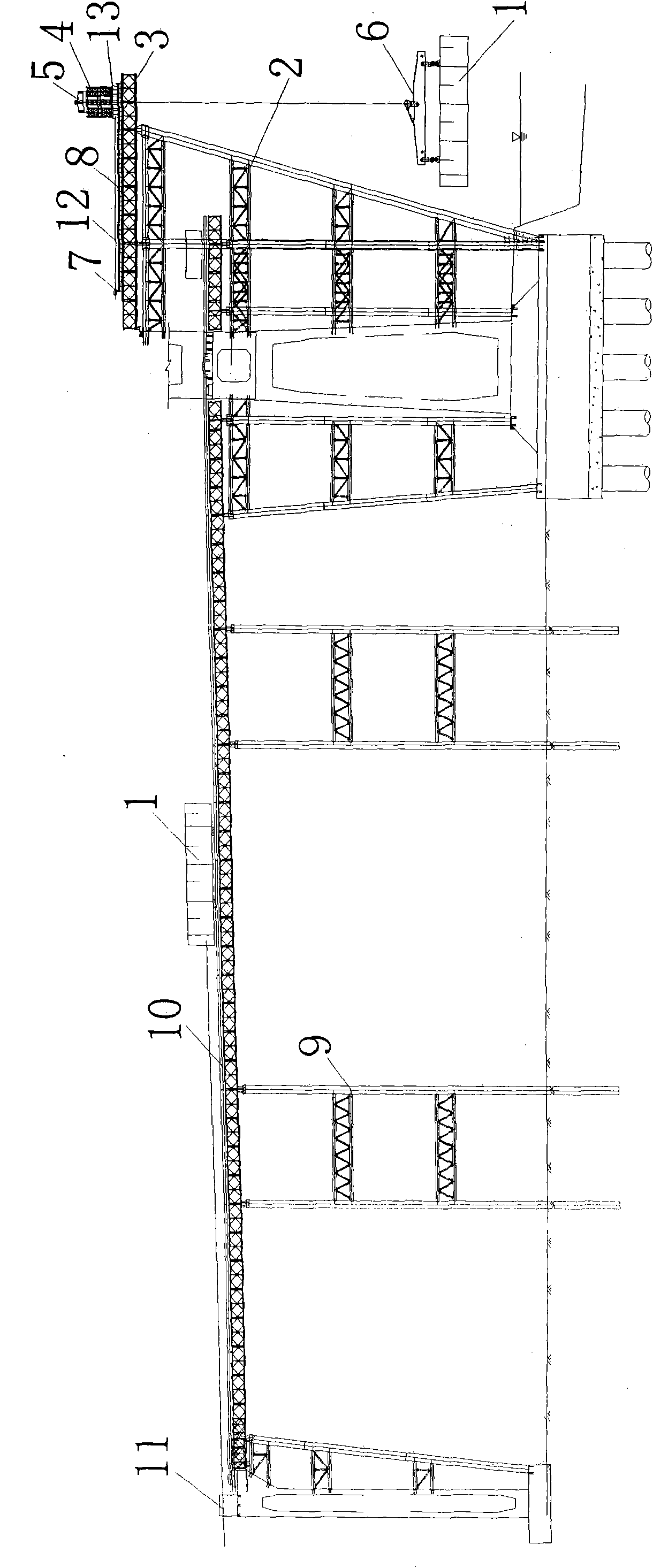

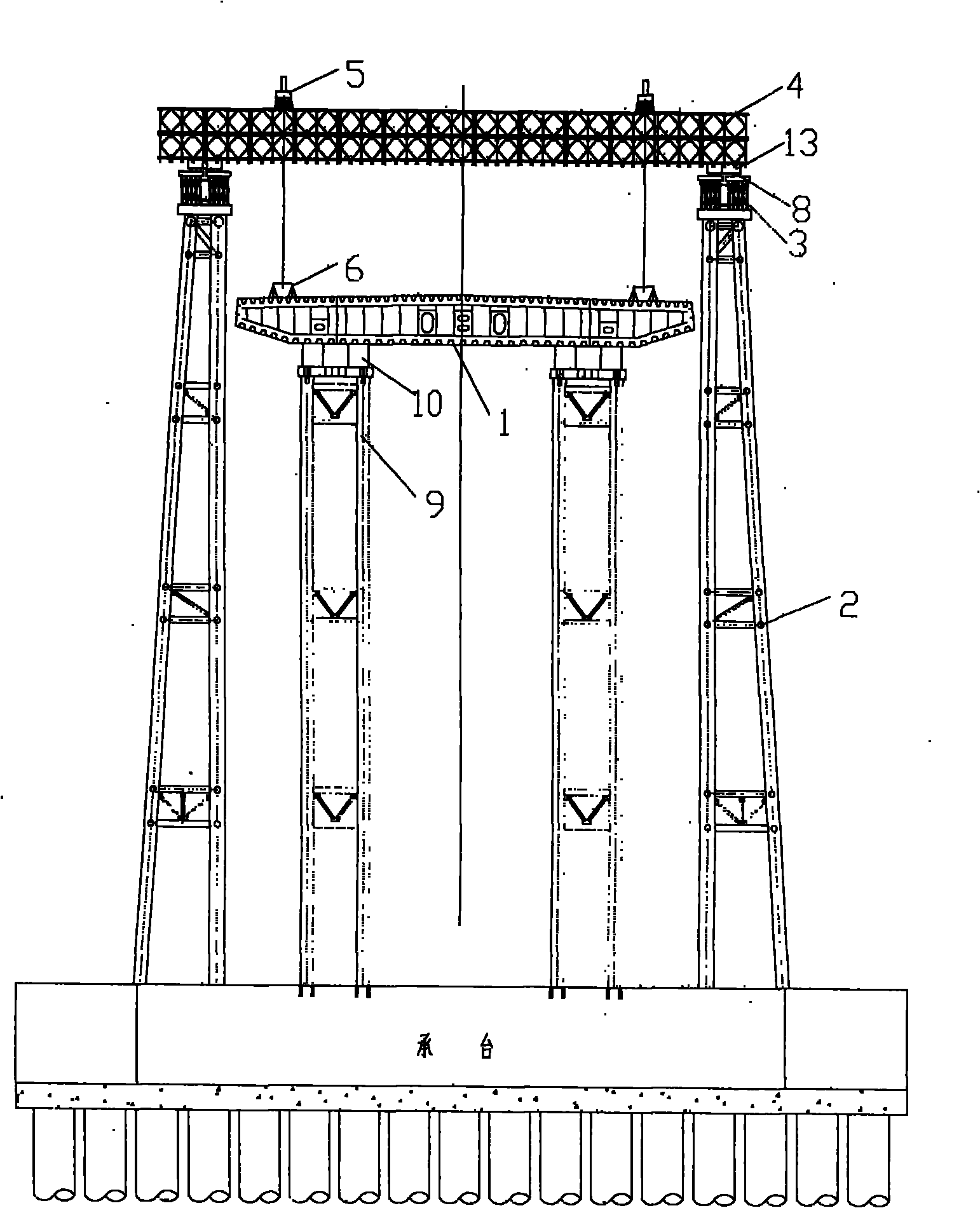

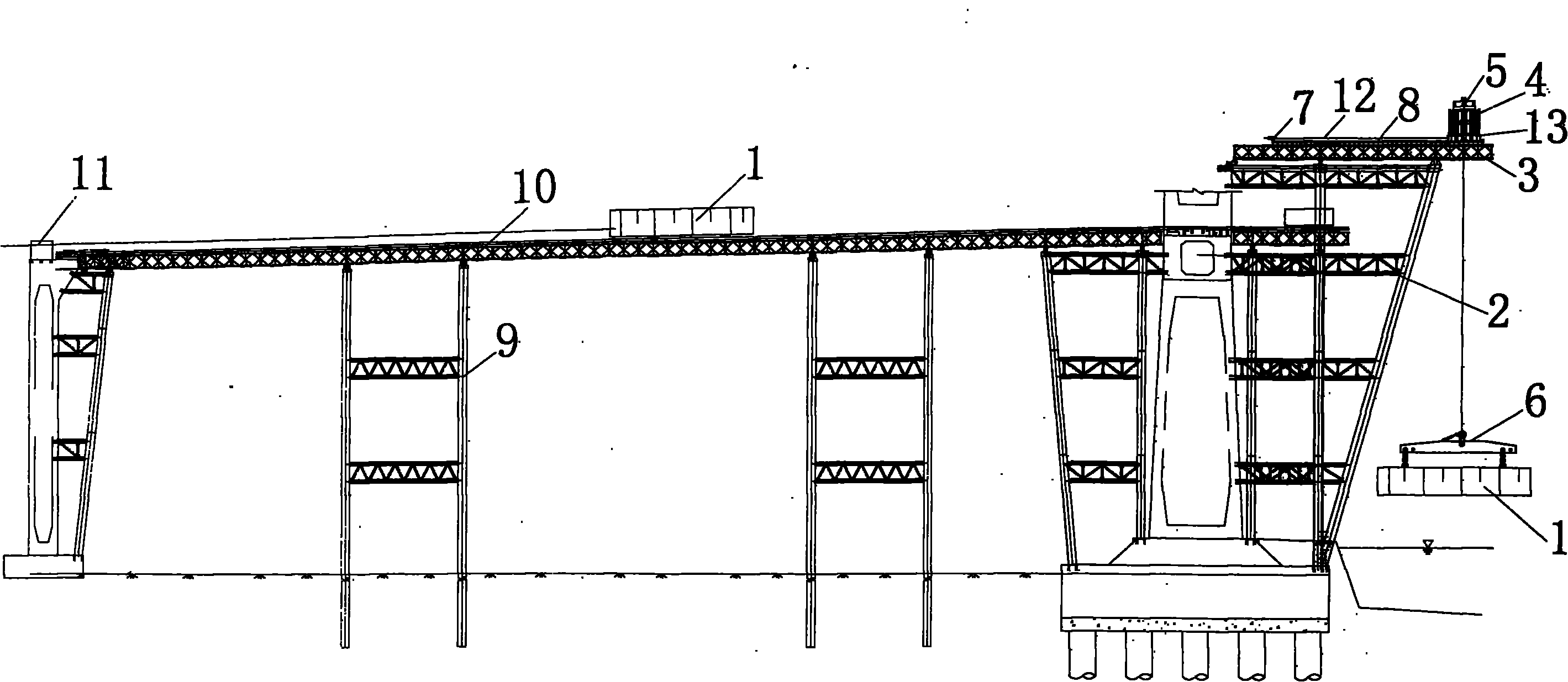

[0024] Such as figure 1 , figure 2 As shown, the present invention is a lifting system for large-tonnage steel box girder in land and shoal areas, which includes two parts: a hoisting system for steel box girder segments and a sliding platform;

[0025] The lifting system includes: lifting bracket 2, lifting longitudinal beam 3, lifting beam 4, lifting device 5 and walking device; the lifting system is arranged next to the pier near the channel, and the river bed at the position of the lifting bracket is excavated to Meet the needs of transportation and parking of steel box girder segments. The traveling device includes: traveling base 13, slide 8, jack 7, steel strand 12, PTFE sliding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com