Front axle automatic meshing device of cross-country four-wheel-drive vehicle

A four-wheel drive and meshing device technology, applied in control devices, vehicle components, transportation and packaging, etc., can solve problems such as unreliable electronic components, insufficient electronic driving force, and inability to shift gears in time, so as to improve fuel economy, Improve convenience and reliability, and compact layout of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

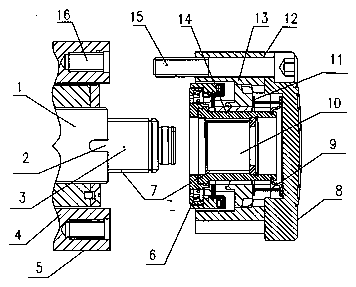

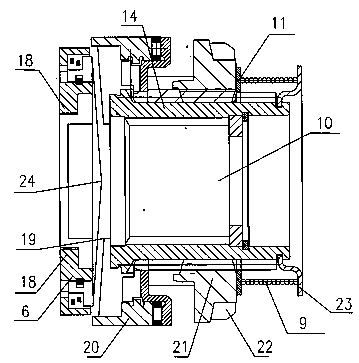

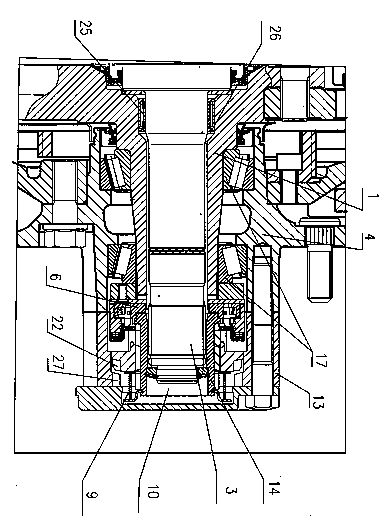

[0012] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0013] An automatic engagement device for the front axle of an off-road four-wheel drive vehicle, including a power transmission part 5 composed of a front wheel hub 4, a steering knuckle 1 and a front axle half shaft 3, the tires are mounted on the front wheel hub 4, and the outer wall of the steering knuckle 1 passes through the cone The bearing 17 is fixedly installed in the middle of the front wheel hub 4, and the drive shaft connected with the engine power is connected with the front axle half shaft 3. The left end of the front axle half shaft 3 is installed in the middle of the steering knuckle hole 26 of the steering knuckle 1 through the roller bearing 25. Automatic wheel side locker 8 is made up of housing 13, base 14, gear 6 and return spring 9, the right end of front axle shaft 3 stretches in the base hole 10 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com