Improved clamp structure of band sawing machine

A band saw machine and clamp technology, applied in clamping, sawing machine device, metal sawing equipment, etc., can solve the problems of occupying operating space, lack of operation safety, and operator injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

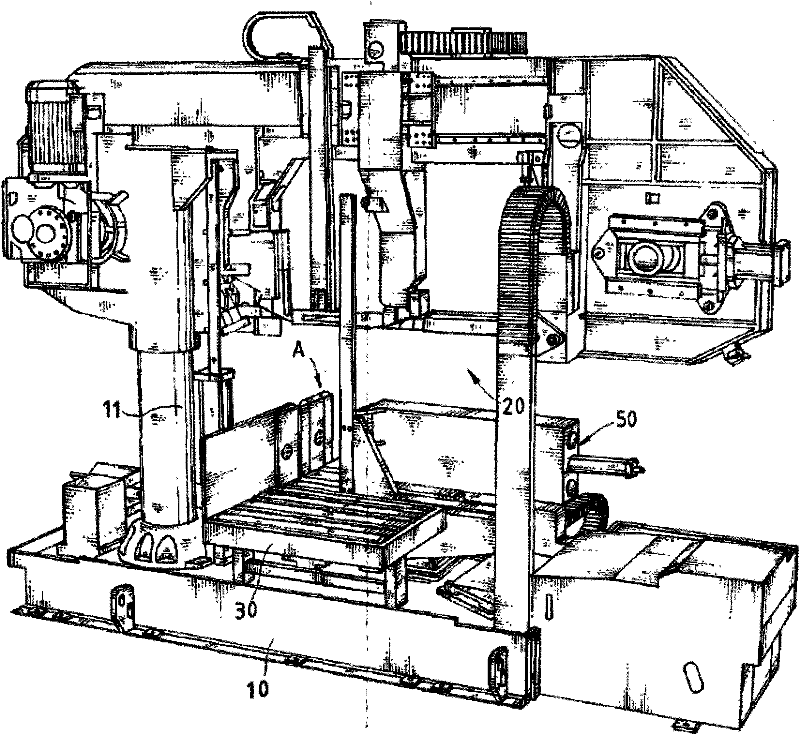

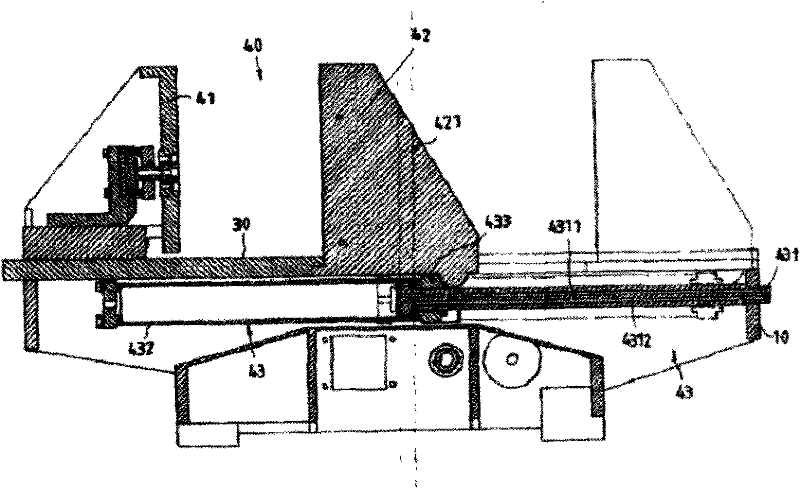

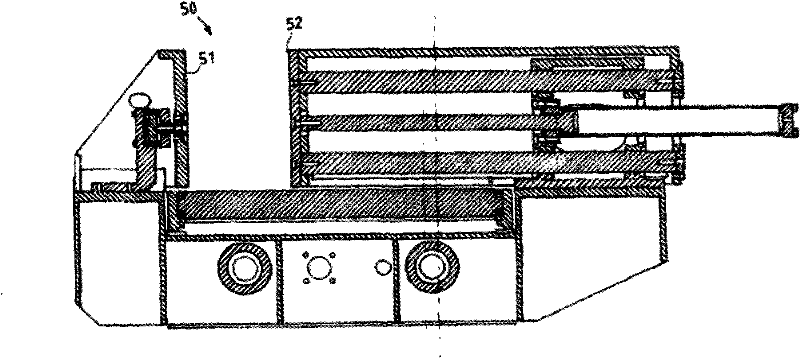

[0022] Example: First, please refer to Figure 1 to Figure 3 As shown, the present invention is an improved clamp structure of a band saw machine. The band saw machine has a base 10, a machine column 11 is fixed on the top surface of the base 10, and a machine column 11 is arranged on the top of the machine column 11. A sawing structure 20, the sawing structure 20 moves up and down with the machine column 11; in addition, the top surface of the base 10 is adjacent to the upper surface of the machine column 11, and a conveying track 30 for conveying workpieces is arranged, and the conveying track 30 A clamp structure 4 is installed at the setting position, and the clamp structure 4 has two first clamps 40 and a second clamp 50 with appropriate spacing, and the first and second clamps 40, 50 have first and second clamps respectively. The fixed clips 41,51 and the first and second movable clips 42,52, between the first and second fixed clips 41,51 and the first and second movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com