Fully automatic production device of convenient miscellaneous-cereal glutinous porridge

A technology for whole grains and production devices, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of easy loss of nutrients, high production temperature, no uniform motion driving device for steel mesh belt rings, etc., and achieves golden color and luster. Easy maintenance, fast heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

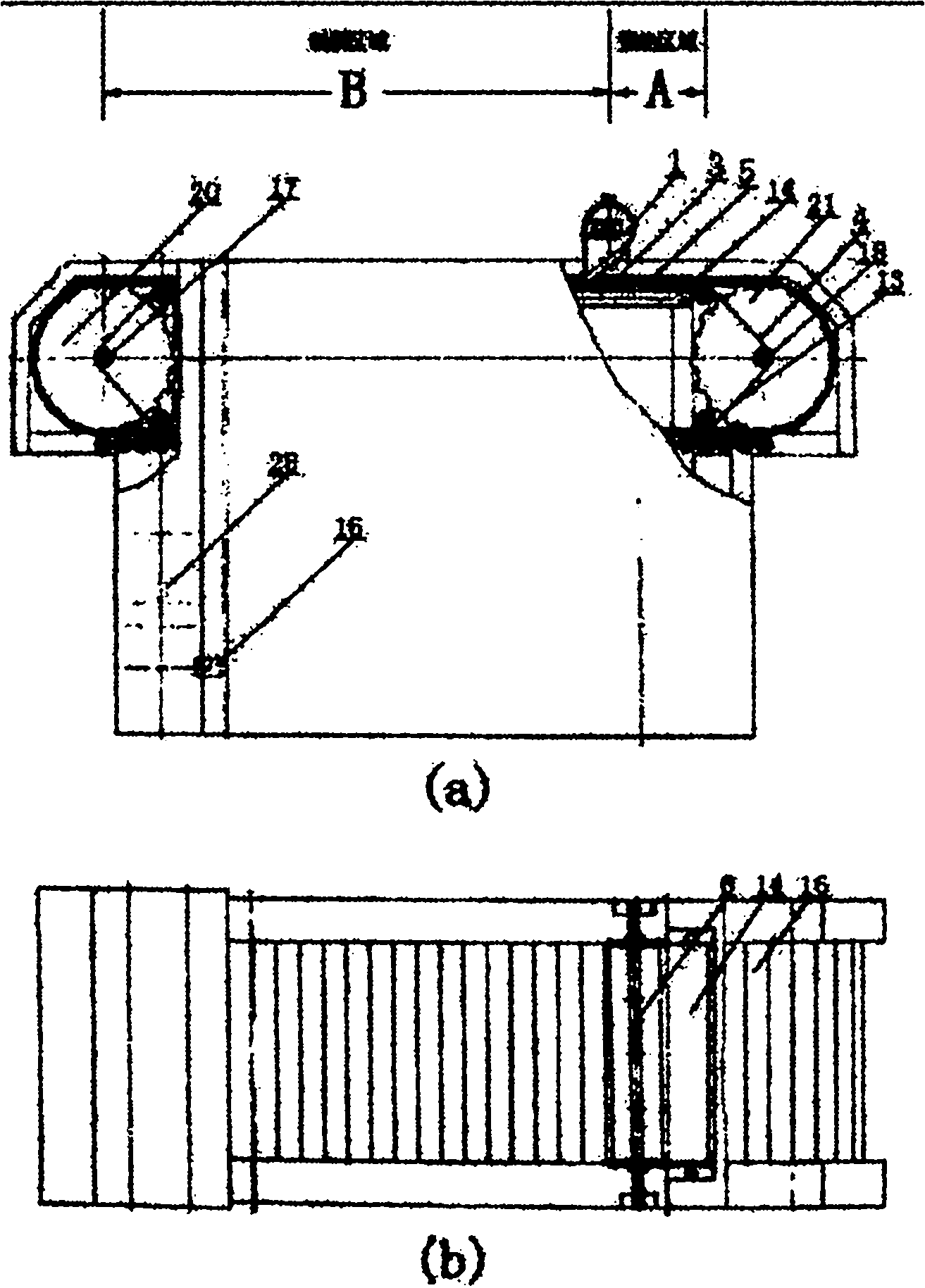

[0022] Such as figure 1 (a) and figure 1 As shown in (b), this embodiment includes: a film-making head 1, an open shaft seat 2, an electromagnetic furnace heating table 3, a steel plate ring belt 4, and a crawler-type workbench 5, wherein: the open shaft seat 2 is fixedly arranged on the crawler-type workbench On both sides of 5, the central axis of the film-making head 1 is set on the open shaft seat 2 and the three feed ports above the film-making head 1 are connected to the pump through hoses, and the steel plate ring belt 4 is sleeved on the crawler-type workbench 5. The inner side is located above the heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com