Device and method for sterilising plastic parisons

A technology for plastic parisons and plastic containers, which can be used in disinfection, chemistry, etc., and can solve problems such as danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

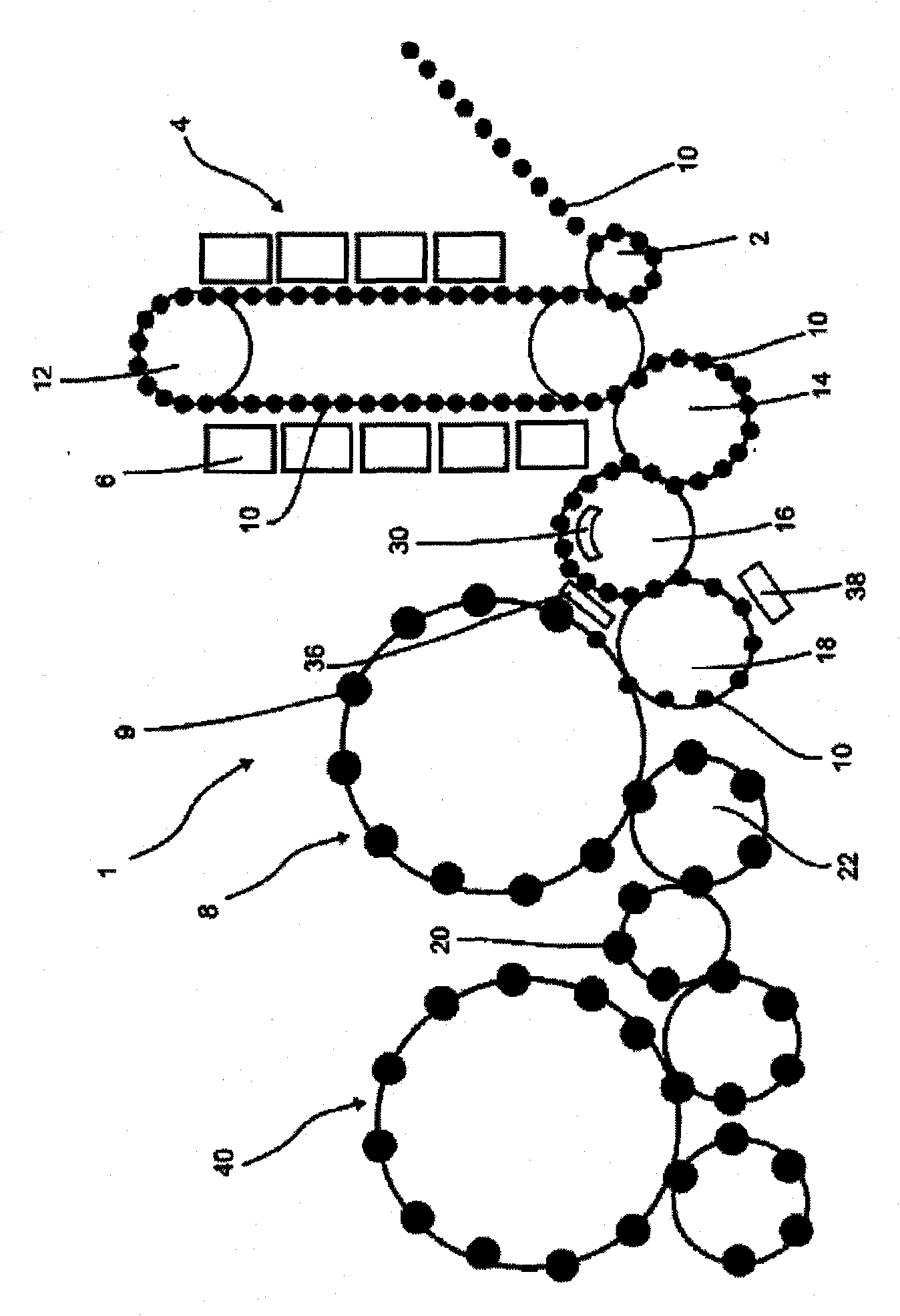

[0030] figure 1 is a rough schematic diagram of a device according to the invention.

[0031] The device 1 has a feeding device 2 which supplies parisons 10 to a heating device 4 in a timed manner or in precise distribution. In this case the heating device 4 has a plurality of heating elements 6 which are each arranged on the outside of the parison 10 in the longitudinal direction of the heating device. Reference numeral 12 designates a conveying device, such as a continuous conveying chain of a corresponding conveying container 10 through the heating device 4 . A conveying device 14 or a subunit 14 of a conveying device follows the heating device 4 . The conveying device 14 is a so-called distribution delay star wheel, by means of which, for example, the distribution between the parisons 10 can be altered. The reference T designates a conveying path along which the plastic parisons 10 or the subsequent plastic containers 20 are conveyed.

[0032] The conveying device 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com