Throttle body negative pressure testing device

A technology of a throttle body and a testing device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as the stability and improvement of the unfavorable throttle body, the inability to guarantee the product quality, the cumbersome operation process, etc. problem, to achieve the effect of simple structure, convenient operation and improved detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

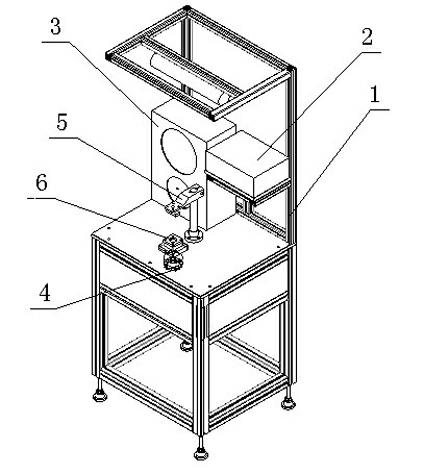

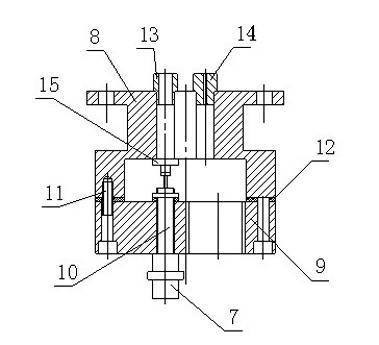

[0014] like figure 1 , throttle body negative pressure testing device, which includes aluminum alloy bench 1, stepper motor controller 2, negative pressure display 3, negative pressure switching chamber 4, clamping mechanism 5 and positioning platform 6, clamping mechanism 5 and The positioning platform 6 is fixed on the mounting plate including the aluminum alloy stand 1, the throttle body is fixed on the positioning platform 6 and clamped by the clamping mechanism 5, and the negative pressure switching chamber 4 is installed under the mounting plate, and the negative pressure switching chamber 4 is Switchable, the negative pressure switching chamber 4 is composed of an upper cover 8, a lower cover 9, a measuring hole, a threaded cylinder 10, a plug 15, an air inlet joint 7, and a connecting screw 11. At l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com