Pressure-while-drilling measuring device and measurement method thereof

A measuring instrument and formation pressure technology, applied in the field of pressure measuring instruments and its measurement, can solve the problems that the formation pressure data is not real-time, and the formation pressure can not be monitored in real time while drilling, so as to achieve easy start-up and shutdown, avoid the difficulty of going into the well, The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

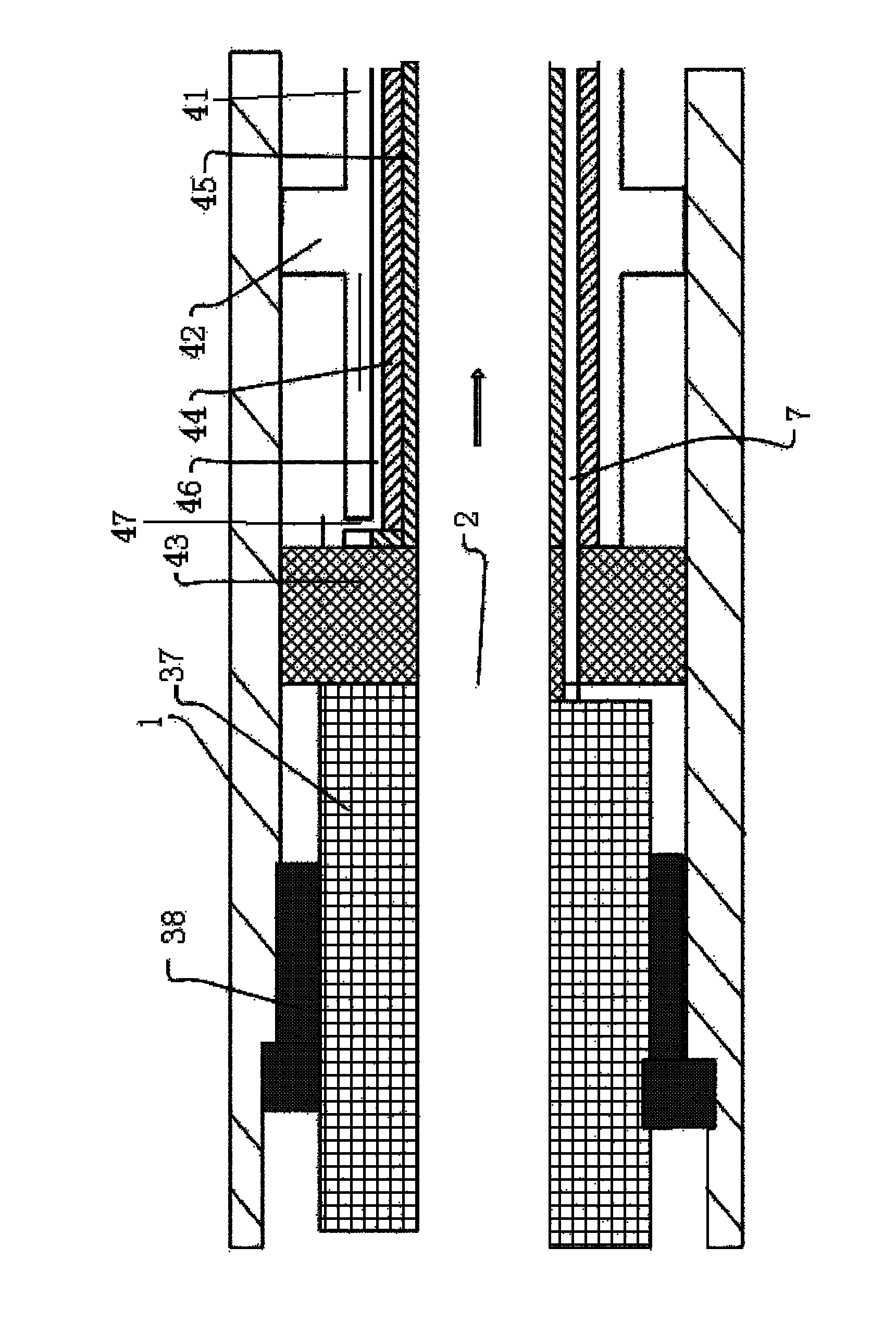

[0016] Such as figure 1 As shown, the present invention includes an outer casing 1 of the device, and a central flow channel 2 is arranged in the outer casing 1 . The outer casing 1 is provided with a diverting and pressurizing mechanism 3 , an actuator 4 and an oil circuit reversing mechanism 5 in sequence. The actuator 4 is provided with a suction mechanism 6 .

[0017] Such as figure 2 As shown, the flow splitting pressurization mechanism 3 includes a splitter tube 31 arranged in the outer shell 1, a splitter channel 32 is arranged between the splitter tube 31 and the outer shell 1, and the inlet end of the splitter tube 31 is provided with a communication splitter channel 32 and a central flow channel. Channel 2 split inlet 33. A hollow splitter piston 34 is arranged in the splitter cylinder 31 , a spring 35 is arranged between the splitter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com